Revolutionary manufacturing technology

The world's first fully automatic folding center for precise and efficient sheet metal processing

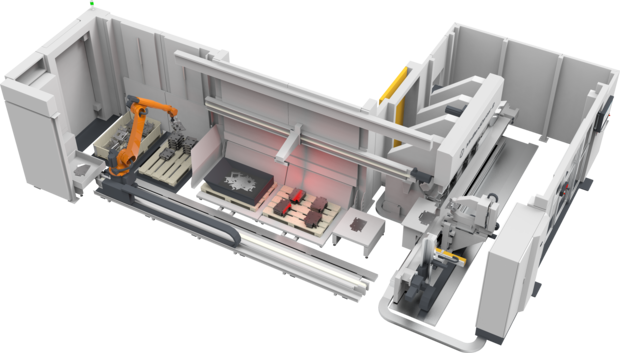

The RAS MiniBendCenter of the second generation is an innovative panel bending center that sets new standards in automated sheet metal processing. As the world’s first fully automated folding center for small parts, it enables seamless automation across the entire production chain: from automatic tool setup and blank loading, to precise alignment and measurement. A smart manipulator positions the sheet metal with high accuracy for the bending process, which can be performed both upwards and downwards.

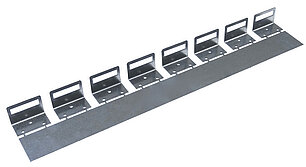

Fully automated bending is possible from sheet sizes as small as 50×40 mm, making the system ideal for manufacturers who demand maximum precision in small-part sheet metal fabrication.

- Only swivel bending center for small parts starting at 50x40 mm

- Automatic easy loading by robot (from bulk material or from stack)

- Automatic unloading by robot (stack on pallet or bulk material on pallet with frame)

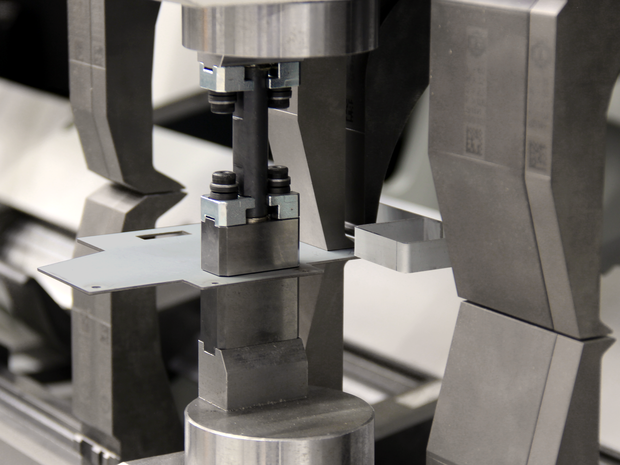

- Automatic tool set-up

- Scanning of the supplied blanks

- Servo-electric manipulation for bent part positioning

- Automatic bending sequences with up and down bending

- Maximum precision and repeat accuracy

- Unmanned operation during the night shift

Fully automatic bending of

even complex parts up to

3 mm sheet steel

Efficiency and precision thanks to high-precision servo-electrics and intelligent robotics

With the introduction of high-precision servo-electrics, the MiniBendCenter 2 sets new standards in terms of efficiency and precision. The integration of an intelligent robot revolutionizes the loading of punched or laser-cut blanks as well as the unloading of the finished bent parts, which it deposits or stacks unsorted as required. The newly implemented pallet changing station optimizes the material flow by providing a central point for feeding in new blanks and removing the processed parts. With these innovations, the MiniBendCenter 2 not only guarantees low unit costs, but also a quantum leap in productivity in automated sheet metal processing.