Blank loading

Intelligent robotic blank loading

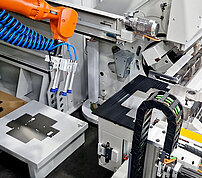

A camera system enables the intelligent loading robot to recognize the position of the blanks of a bulk material quantity on a pallet. The software calculates which blanks form the top layer and which parts the robot can access. The robot then picks up one of the available blanks and feeds it to the MiniBendCenter 2.

Of course, the robot can also grip the blanks in stacks. The blanks do not have to lie exactly on top of each other. And the best thing is that the robot does not need to be taught or programmed. Simply start a bending program and the machine does the rest.

- No programming or teaching necessary

- Robot grips the blank and feeds it to the bending center

- Parts that are upside down are sorted out

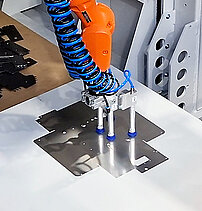

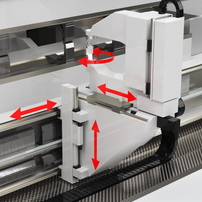

Multifunctional vacuum gripper

The multifunctional vacuum gripper allows different blank geometries to be fed without changing suction cups. Each individual suction cup is programmable and can be controlled separately. Two suction cups are fixed and the position of two suction cups can be adjusted.

- Additional flexibility gain for very different blanks

- Ideal for unmanned production

- The arrangement of the suction cups enables a variety of unloading options

Bending sequence

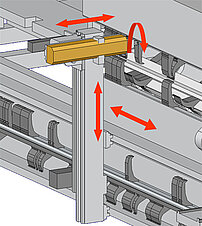

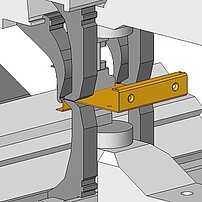

Automatic tool setup

The fast and automatic tool changer places the clamping and bending tools into position. Tools not used for a job are stored in the tool magazine. Due to its rotation axis in the gripper, the tool changer can place a tool in the upper or lower clamping beam as well as in the upper and lower folding beam.

- Automatic tool change in the shortest possible time

- Precise took positioning

- Unmanned shifts due to automatic tool setups

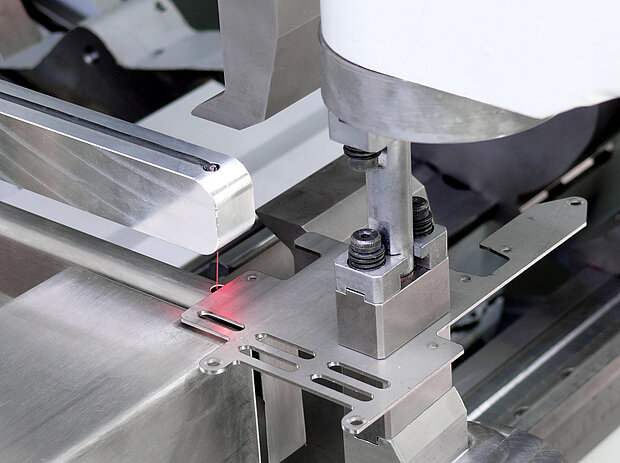

Manipulator

In the new generation of the MinibendCenter 2, the manipulator clamps, rotates and positions the bent part using high-precision servo-electric drives. As it can even move between the tools, its design opens up an extremely wide range of applications.

- Precise positioning and turning

- Highest bending precision

- Constant repeat accuracy

- Very small parts can be bent

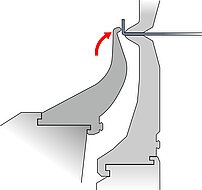

Bending up and down

The folding beams of the MiniBendCenter 2 can bend the sheet metal flanges up and down. The part does not need to be flipped when the bending direction changes. The workpiece always remains horizontal. There is no need to lift the part as with press brake bending.

- Simple bending sequences and therefore simple programming

- Fast bending cycles

- Low unit costs

Unloading and stacking bent parts

Intelligent robotic unloading

The intelligent robot not only loads the blanks, but also unloads the bent parts. The robot knows the position of the provided pallets and unloads the finished parts there. The robot can set up several stacks next to each other.

If the bent parts are not sensitive, the robot can also place them unsorted in a bulk container.

- No programming or teaching required

- The robot can unload finished parts stacked or unsorted