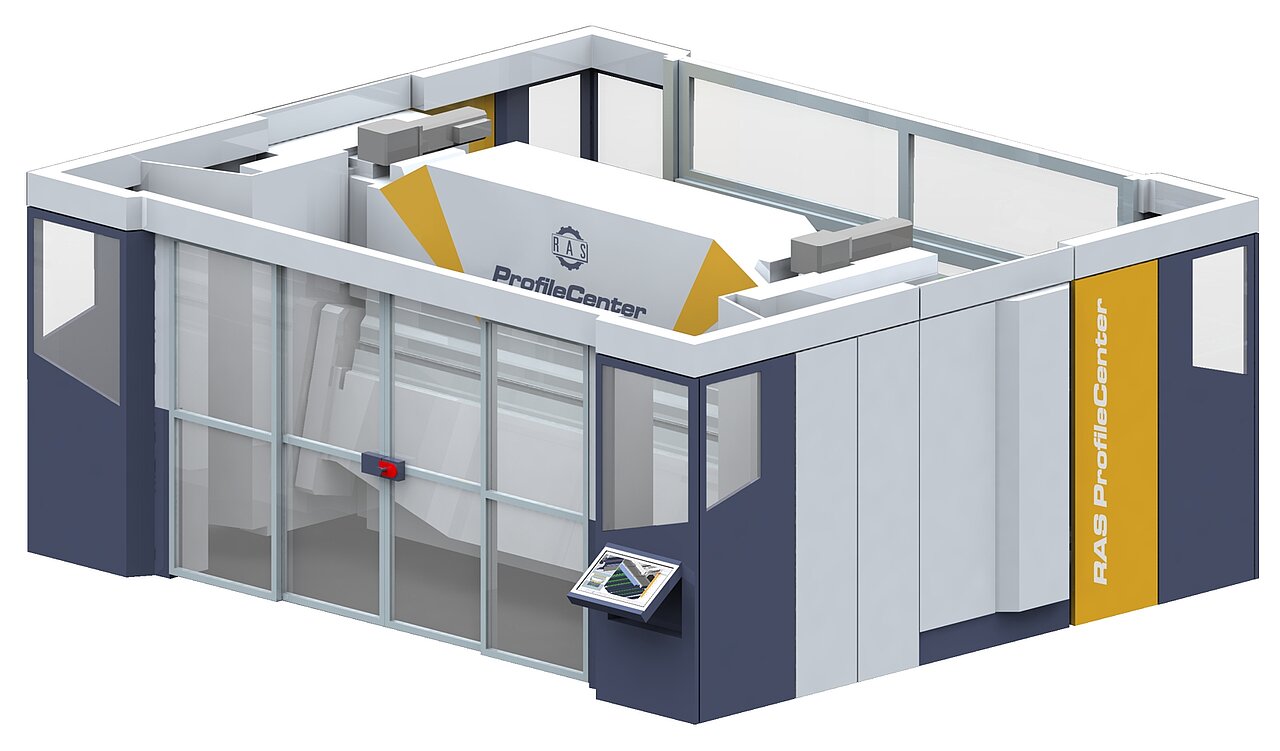

Profile bending

Precisely in batch size 1

Flexible and automatic profile bends profiles such as door frames, window frames, elevator entries, electrical cabinet components or cable ducts in batch size 1. The unique FlexGripper handling system moves, rotates and flips the blank automatically during the bending process.

Machine highlights

- Fully automated squaring, handling, bending and

unloading of profiles - Flexible bending - up and down

- Automated bending sequences: short cycle times, low costs per part

- No manual interaction needed: high productivity

- Highest levels of precision and repeatability

- Scratch-free bending: no tool wear

- Ideal for batch size 1

- Machine automatically adjusts to thicknesses and material type

- Automatic one-click part programming

- No operator bending expertise required even for complex profiles

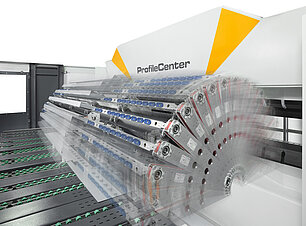

Complex geometries can

be bent due to large free

areas around the tools