The video shows the production speed of air ducts produced in a sequence on the RAS DuctZipper in L-shape. The sheet edges will be just inserted into the guide rail and clamped with the Autopilot. While the first duct runs through the machine a second operator can already insert the following duct. This increases the throughput and lowers the unit costs.

Eingesetzte Maschine:

DuctZipper L-Form

The RAS DuctZipper duct seaming machines reduce the traditional three steps (rollform the receiver lock, rollforming the flange and finally closing the seam) down to only one easy run through the machine. The result is a clean joint and an extremely tight duct. When producing large size air ducts the Duct Zipper in L-shape shows its superiority by easy use, halved staffing needs and doubled operating speed and 40–50% less floor space.

Eingesetzte Maschine:

DuctZipper L-Form

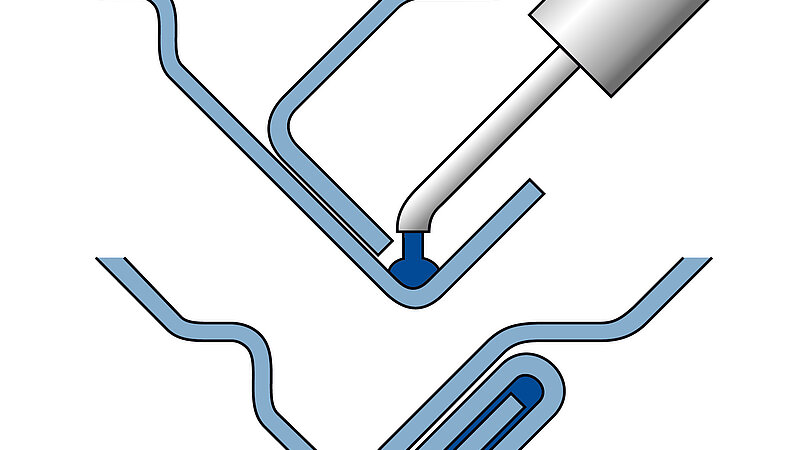

While producing air ducts on the RAS DuctZipper, the SealJet injector seals the seam joint during the run. The SealJet injects a sealant into the seam pocket before the rollers of the DuctZipper close the seam. Sealing is clean, fast, meets hygiene requirements, is corrosion and temperature resistant.

Eingesetzte Maschine:

DuctZipper V-Form

The RAS DuctZipper-V forms and closes the seamed joint on small and medium size air ducts. Professional air ducts can hardly be produced faster, more easily and more economically. The RAS DuctZipper closes a duct bent on three sides with a seam in a single pass. The support system guides the duct through the DuctZipper and simplifies material handling for small and medium size ducts. The AutoPilot and the improved entry guiding system ensure a consistent seaming quality and super tight air ducts.

Eingesetzte Maschine:

DuctZipper V-Form