The RAS Multibend Center bending Center can create radii on heat pump covers from individual bending steps. Almost any radius with the highest quality standards can be bent. Means: Maximum part design flexibility and no additional investment in special tools.

Eingesetzte Maschine:

Multibend-Center

Panel bender RAS Multibend-Center with 2 station gantry loader at Arcobaleno in Italy bends panels for pellet heating systems. This however is just an example of the variety of products, this Northern Italian job shop folds on the flexible metal bending system.

www.arcobalenolamiere.com

Eingesetzte Maschine:

Multibend-Center

The UpDown RAS XLTbend folding machine for semi-automatic bending of wrapper for a heating stove made of 3 mm mild steel. The hybrid gauging system automatically positions the part for subsequent bends. The virtual navigator (ViN) indicates the exact blank loading position to the operator.

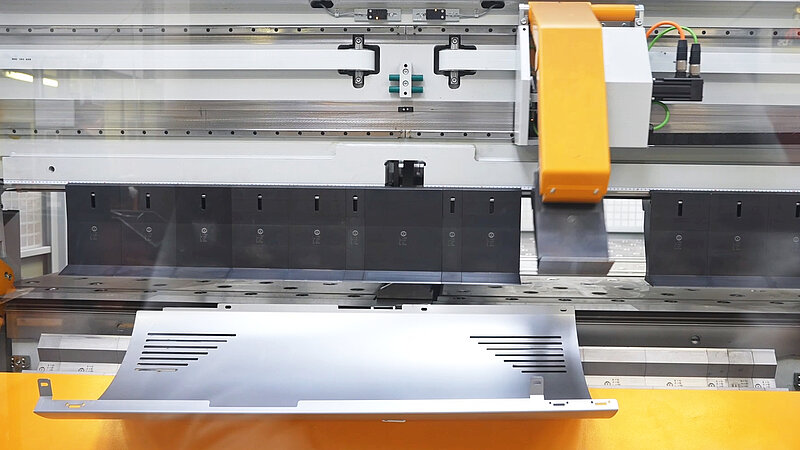

On the Hargassner shop floor space is limited. The pallet oven specialist therefore requested a special solution with an intelligent loading and unloading robot for the production of their boiler trims. The blanks are provided by a Stopa storage system and the robot can pick and load blanks from up to 4 different stacks of material without a need of being programmed. The unloading robot stacks the finished parts on pallets and also calculates its movements fully automated.

www.hargassner.at

Eingesetzte Maschine:

Multibend-Center

Producing and distributing hot air has been the job of Gustav Nolting GmbH for almost 100 years. The German company specializes in innovative air heating technology. Some of the sheet metal parts are very large and thus ideal for the folding technology. With the RAS XLTbend the company achieved profitability effects significantly above the initial expectations.

www.gustav-nolting-gmbh.de

Over the years, the pellet stove has more and more taken on the role of a well-being stove, but above all it has become a design and decoration object. The RAS Multibend Centers ECO supplies Palazzetti directly with finished enclosure parts for the stoves, which do not need to be post-processed, and this in consistent and visually flawless quality. The quality of the end product in terms of surface finish is outstanding. With the bending center, Palazzetti is highly efficient on one hand, as the automatic tool setup significantly reduces the cycle time of the machining operations. On the other hand, they are very flexible, as the automatic tooling system allows them to switch extremely quick from one program to another.

www.palazzetti.de

Eingesetzte Maschine:

Multibend-Center