In parts for agricultural machinery sometimes formed sections are already in the blank. The video shows how the RAS UpDownBend folding machine handles these situations. When bending large-size and heavy sheetmetal parts for agricultural machinery, the advantages of the UpDown folding technology become obvious. Parts with positive and negative bends can be produced by a single operator as they do not need to be flipped during the bending sequence.

Eingesetzte Maschine:

UpDownCenter-2

The RAS Multibend Center panel bender folds aluminum treadplates and creates tool boxes, as they are often used on pickup trucks. Due to the unique 3D bending technology the treadplate material surface will not be scratched during bending.

Eingesetzte Maschine:

Multibend-Center

The GIGAbend folding machine is the ideal solution for bending heavy parts. This video shows a GIGAbend specially equipped with a gripper system. Our customer Kubota uses this machine bending excavation buckets. He has further automated the machine using a robotic loading and material handling system.

www.kubota.com

Eingesetzte Maschine:

GIGAbend

When bending large-size and heavy sheetmetal parts for agricultural machinery, the advantages of the UpDown folding technology become obvious. Parts with positive and negative bends can be produced by a single operator as they do not need to be flipped during the bending sequence.

www.amazone.de

Eingesetzte Maschine:

UpDownCenter-2

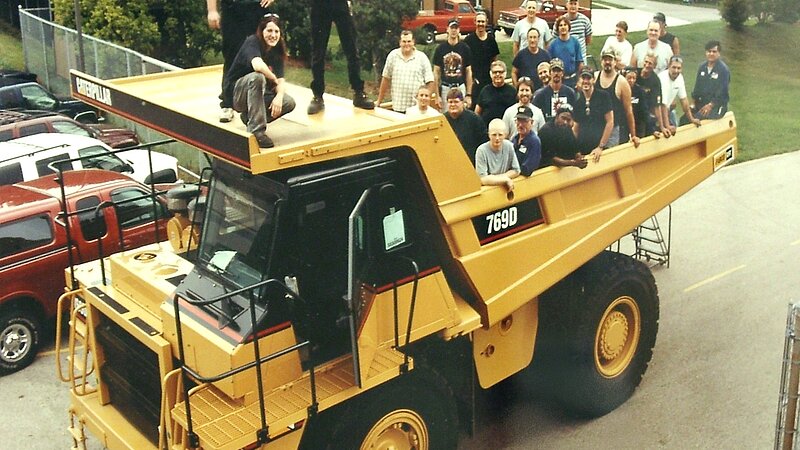

The production principle at Helgesen is networking. As a subcontractor, the company located in Hartford, Wisconsin (USA) is closely associated with its customers. This starts in the joint product design and goes through the flow preparation until delivery. Nate Marshall explains, “RAS GIGAbend is one of our core machines for the production of platforms on the right and left of Caterpillar's construction truck. We produce 15 of these platforms every day. All panel type and structural components are bent on the GIGAbend.“

www.helgesen.com

Eingesetzte Maschine:

GIGAbend