Low-cost solution with all the

functionality of a high-end

bending center

Multibend-Center ECO Bending centers

MBC ECO: Equipment for leather industry

Multibend-Center ECO: Large blanks

ECOauto: Multibend-Center ECO with autom...

Multibend-Center ECO bends pellet stoves

Panel Bender RAS Multibend Center ECO

Multibend-Center ECO: Small batch sizes

Multibend-Center ECO at manufacturer Kim...

Multibend-Center ECO: Shelves

Panel Bender RAS Multibend Center ECO

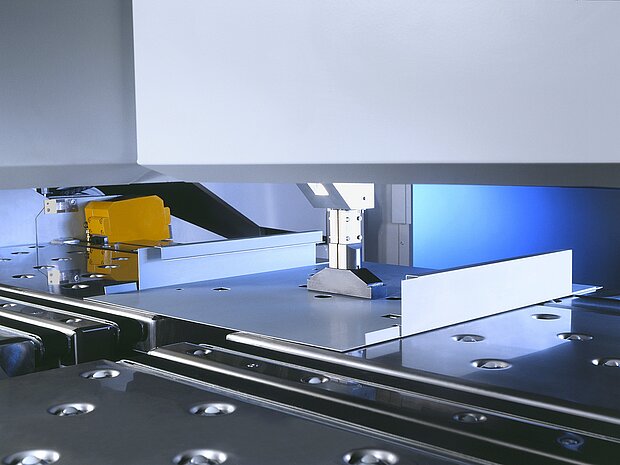

- Manual blank loading

- Manual unloading of bent parts (same side)

- Automatic blank squaring

- Automatic UpDown bending sequences

- Automatic tool setup

- Highest level of productivity

- Highest level of precision and repeatability

- Scratch free bending, no wear of tools

- One-click part programming

- Small floor space required

The equipment package

Multibend-Center ECO panel bender package includes:

- Suction cup measuring table for manual blank loading

- Magic-Eye blank scanner for optical blank measuring

- Automatic blank transfer to the manipulator

- Manipulator for part rotation and positioning

- Up and down bending

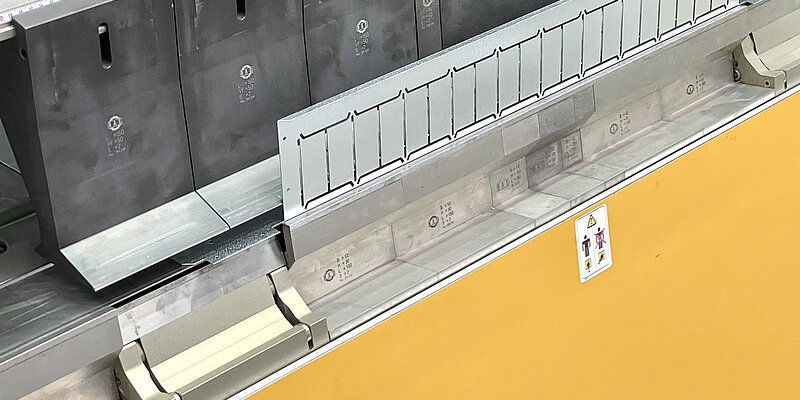

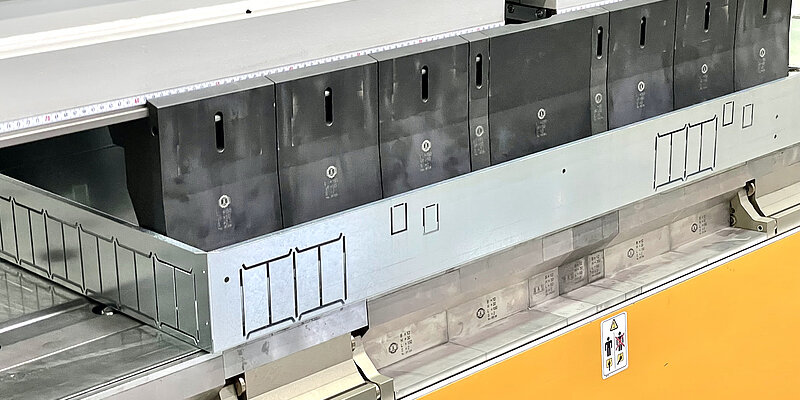

- Tool changer for automatic tool setup

- Tools for the upper beam, bending beam and lower beam

- Roto-foot corner tool for turning in and out of bent flanges

- Automatic transport of the bent parts back to the operator

Optionally the package can be completed with:

- Bendex Office software

- Automatic programming of the bending sequences

- Ranking of alternative bending sequences

- 3D bending sequence simulation

- Software updates of the Bendex Office software for one year

- Folding beam with manual crowning option

- UpDownTools for interrupted bend lines

- Tab tools for bending welding tabs

- Reinforced tools for 2.5 mm mild steel components

|

RAS 79.22-2 ECO |

RAS 79.26-2 ECO |

RAS 79.31-2 ECO |

|---|---|---|---|

| Working length max | 2160 mm / 85" | 2560 mm / 100.8" | 3060 mm / 120.5" |

| Material thickness max (400 N/mm² / 58,000 PSI) | 2.0 (2.5) mm / 14 (13) ga | 2.0 (2.5) mm / 14 (13) ga | 2.0 / 14 ga |

| Box height max (four sides) | 203 mm / 8" | 203 mm / 8" | 203 mm / 8" |

| Blank length max | 2260 mm / 88.9" | 2660 mm / 104.7" | 3160 mm / 124.5" |

| Blank width max | 1500 mm / 59" | 1500 mm / 59" | 1500 mm / 59" |

| Machine dimensions | 7250 x 5500 mm / 285" x 210" | 8050 x 5950 mm / 317" x 234" | 9050 x 6200 mm / 360" x 245" |

CBC Srl manufactures custom equipment for leather goods and shoe factories, specialized in cutting and leather processing. By doing so, the Italian company adds order and efficiency to the leather goods production. At its Prato factory, CBC designs, develops and manufactures the finished products, which are made from steel blanks. These products utilize production space more efficiently, shorten process times and increase workplace safety. The RAS 79.22-2 ECO Multibend Center panel bender, with a bending length of 2160 mm, reduces energy consumption and increases throughput and flexibility. But let's start at the beginning.

Over the years, the pellet stove has more and more taken on the role of a well-being stove, but above all it has become a design and decoration object. The RAS Multibend Centers ECO supplies Palazzetti directly with finished enclosure parts for the stoves, which do not need to be post-processed, and this in consistent and visually flawless quality. The quality of the end product in terms of surface finish is outstanding. With the bending center, Palazzetti is highly efficient on one hand, as the automatic tool setup significantly reduces the cycle time of the machining operations. On the other hand, they are very flexible, as the automatic tooling system allows them to switch extremely quick from one program to another.

Kimmel GmbH & Co. KG started automating manufacturing processes more than 20 years ago. By using a panel bender RAS Multibend-Center ECO with a working length of 2560 mm, the sheet metal parts specialist from Simbach in Bavaria, Germany, is able to react very flexible to order peaks. Volker Kimmel concludes: "With the RAS bending center, we have achieved all our objectives. Easy operation, flexible response to new challenges, low space requirements, and automation within bounds to counteract the increasingly critical labor shortage."