High productivity

due to fast bending

sequences

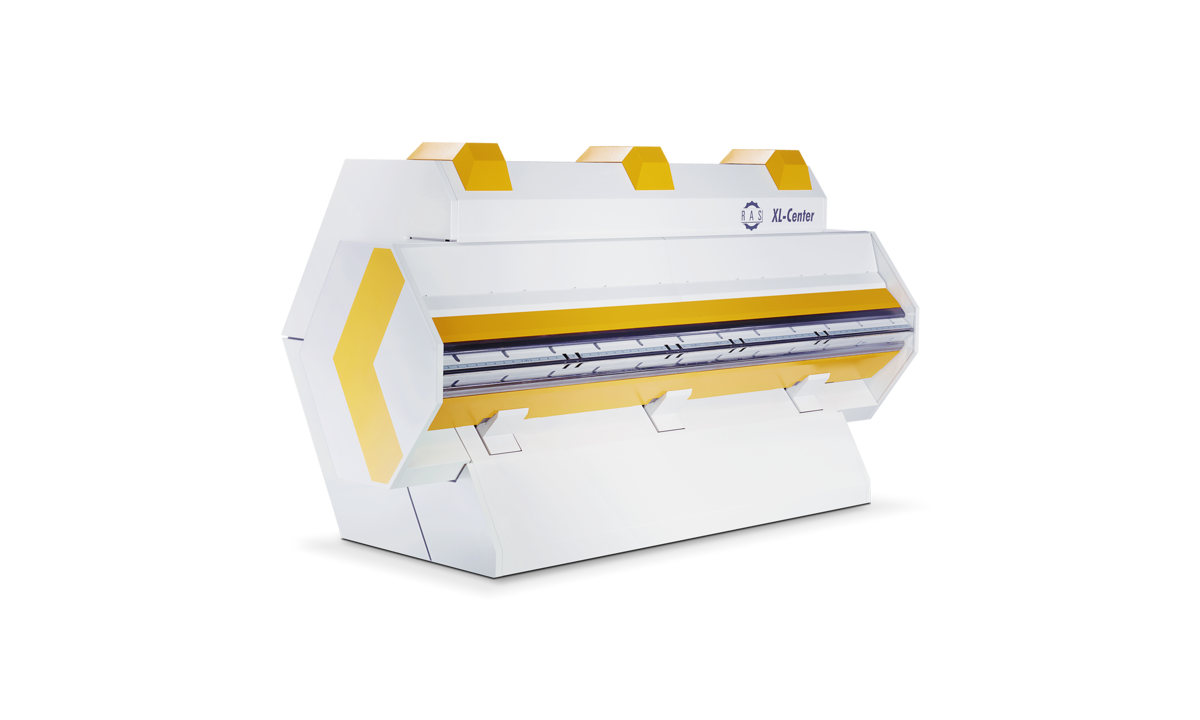

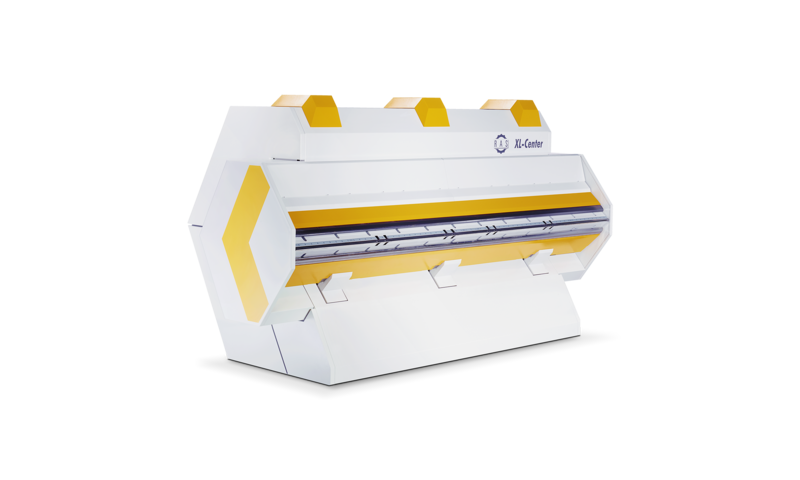

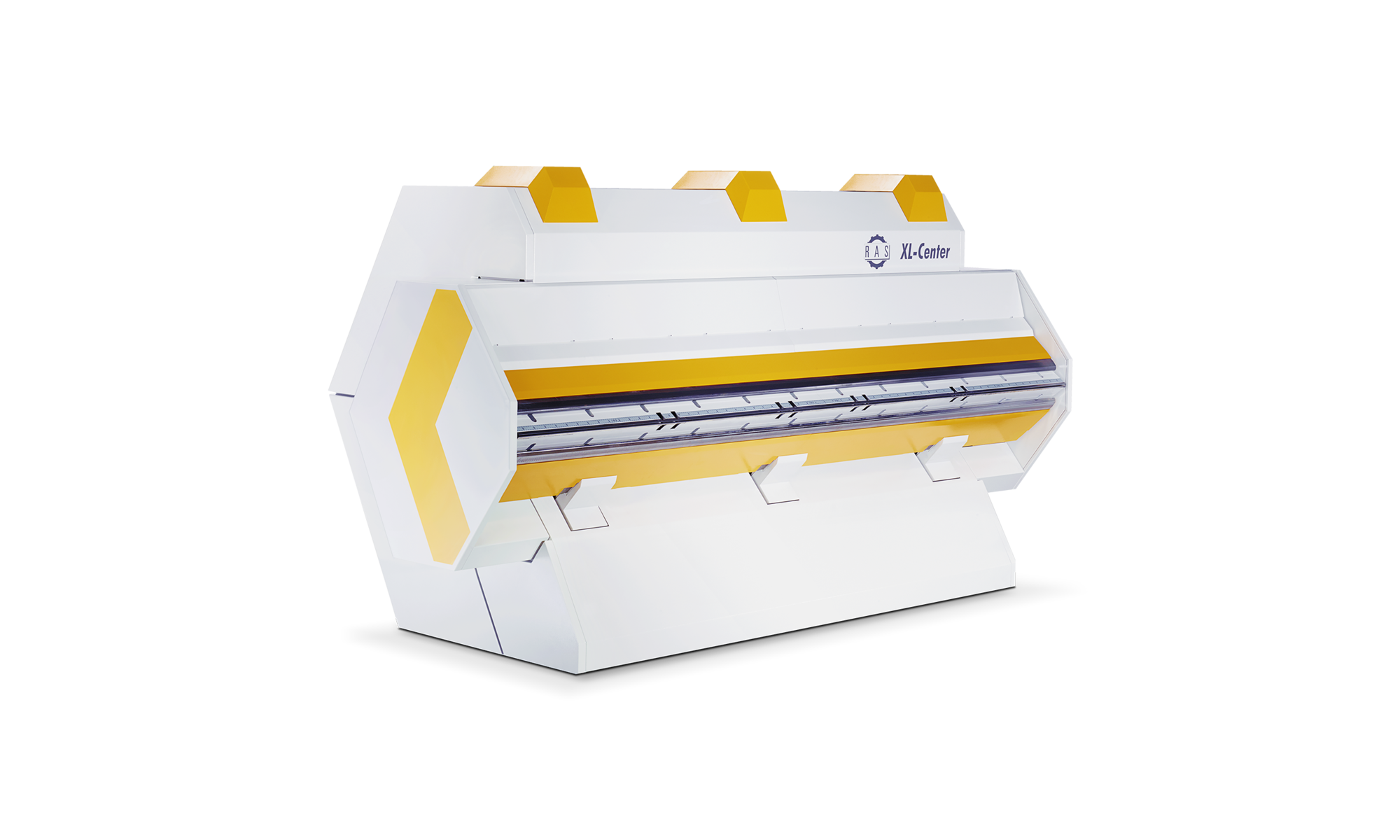

XL-Center Bending centers

RAS XXL Center: 2nd generation long fold...

XXL-Center with slitter: Schütze GmbH

XXL-Center with CutModule

XXL-Center: Complex wall profile

Long folding XXL-Center (8 meter)

RAS XXL-Center: Corrugated parts

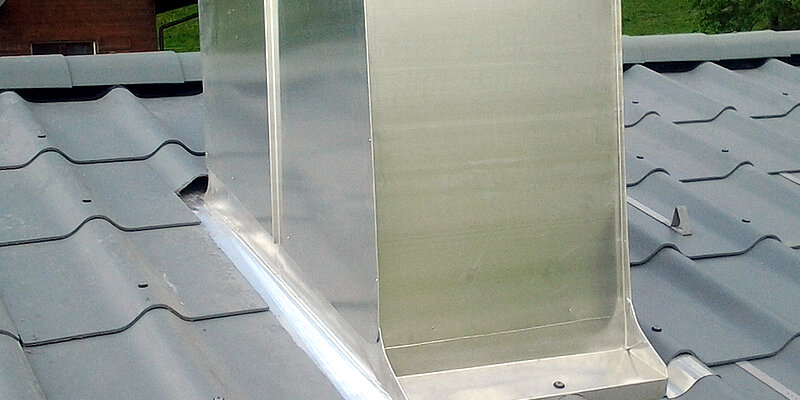

XXL-Center: Skylight dome

XXL-Center: corrugated panel

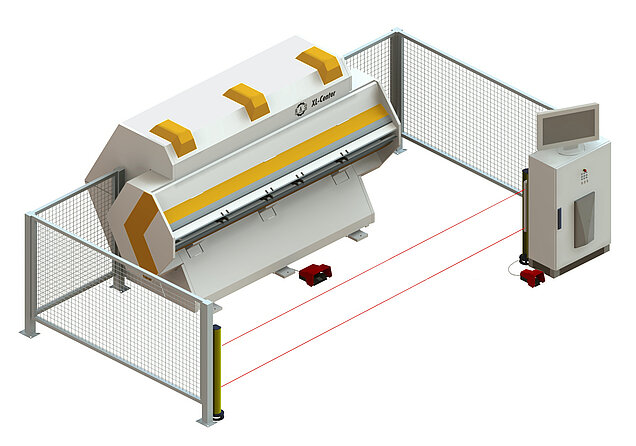

Bending Center RAS XL-Center

Bending Center RAS XL-Center

RAS XL-Center: Tapered parts

Bendex-Mobile and RAS XL-Center

XL-Center: Bending on hems

RAS XL-Center: Toolbox parts

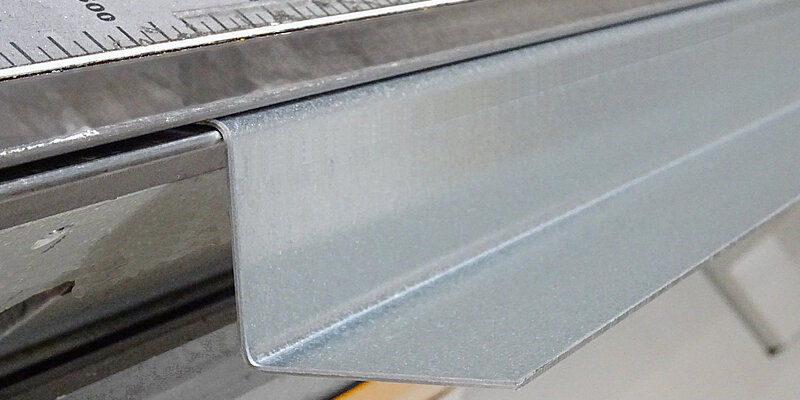

XL-Center: Accuracy on 1.5 mm mild steel

Simple XL-Center programming

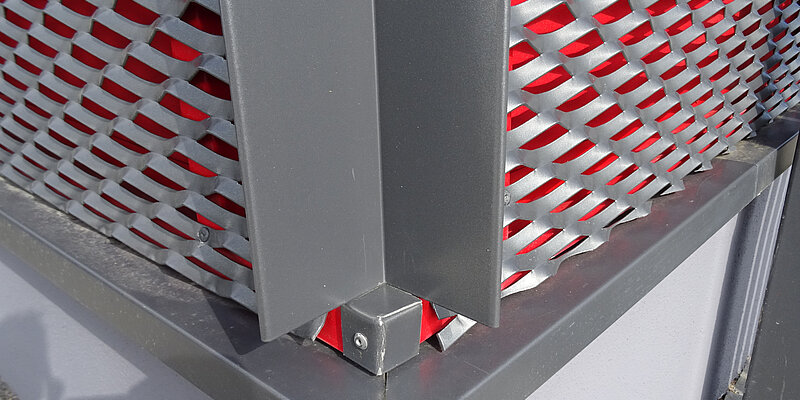

XL-Center: Star-shaped facade profile

RAS XL-Center bends roller shutter box

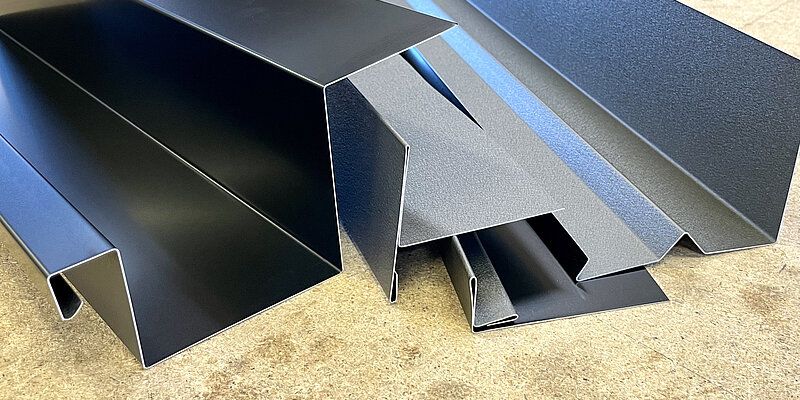

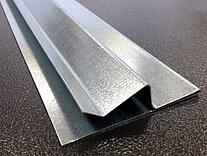

XL Center: Bending building profiles

XL-Center: Large free space

XL-Center: Coping

XL-Center: Part with manual operation

XL-Center: tapered parts

XL Center: Wall coping

XL-Center: Bending a roof ridge

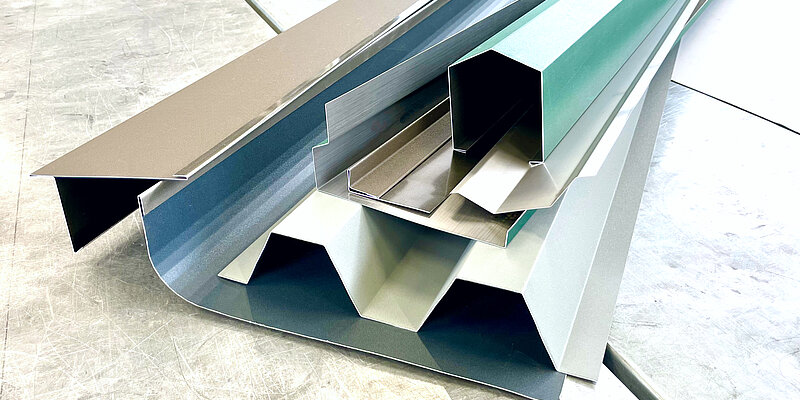

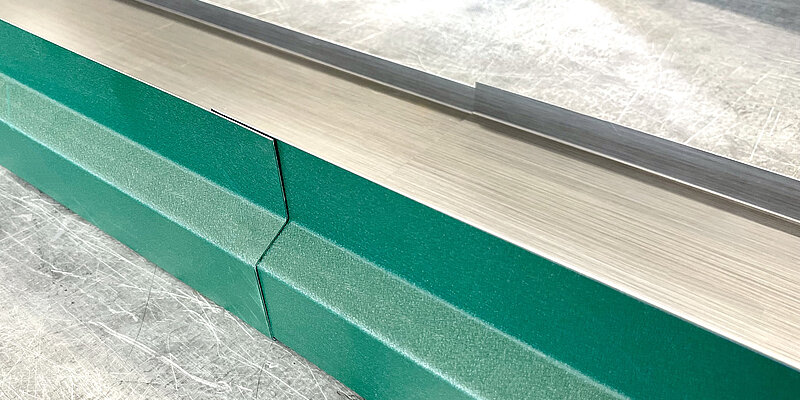

Company Binder: Profile diversity

RAS XL-Center: Complex bending profile

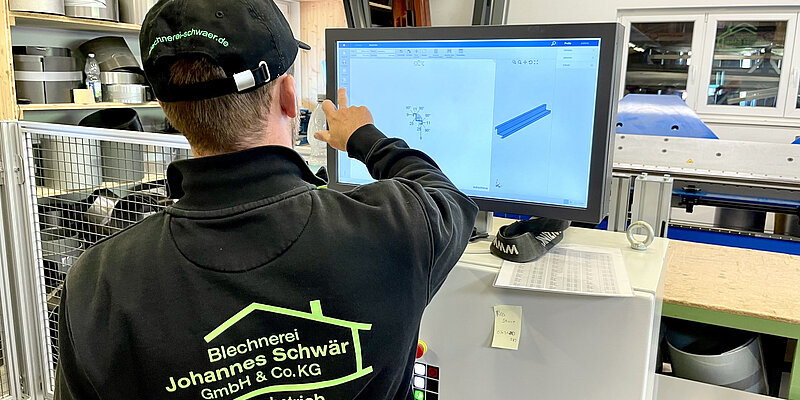

XL-Center at roofer Schwaer

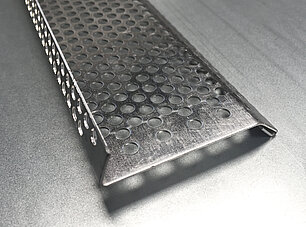

RAS XL Center buckle plate

- Draw a profile on the touch monitor or import a part geometry

- Expert knowledge implemented in software

- Automatic programming of the bending sequences

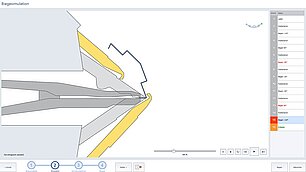

- 2D or 3D simulation of the bending sequence and visualization of possible collisions

- No operator intervention during bending sequence due to up and down bending

- Perfect fitting accuracy and no programming effort for interlocking profiles (tapered bending)

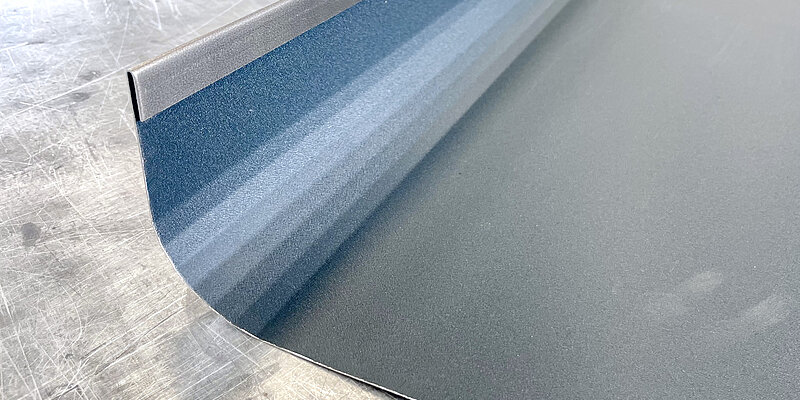

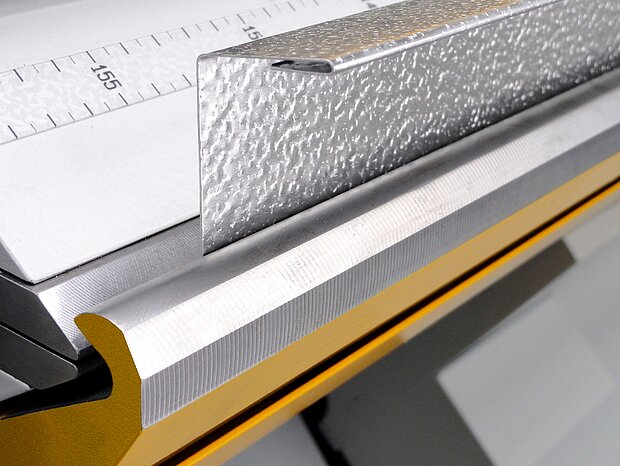

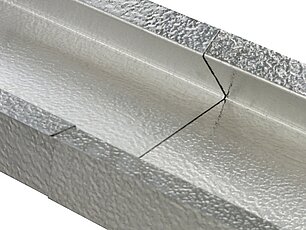

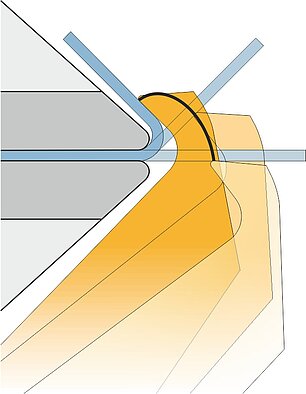

- Scratch-free bending of pre-coated materials due to rolling bending motion

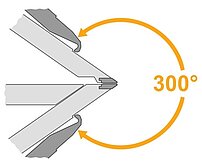

- Large variety of part geometries can be bent due to 300 degree free area in front of the folding beams (patented)

Automated bending

Grip, hold, position

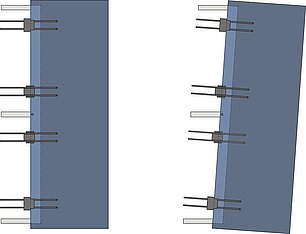

After the blank is loaded the grippers of the XL-Center take over the workpiece and automatically position the part for each bend. The grippers can clamp on straight material, but can also clamp on a closed hem.

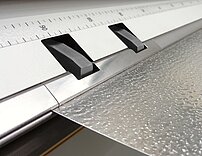

- Gripper position the part automatically for each bend

- Accurate and repeatable flange dimensions

- Fast bending sequences, high productivity, low costs per part

- Automatic re-grip sequence

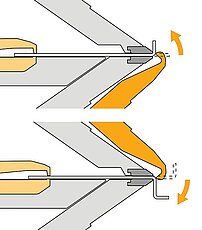

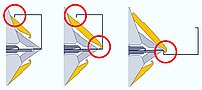

Bending up and down

Up and down folding eliminates a need to rotate the parts. Short cycle times, precision flange dimensions and angles, high levels of productivity and low costs per part guarantee a quick payback of the investment.

- No part flipping required

- Little swivel movement of folding beams

- Fast bending sequences

- High productivity, short payback period

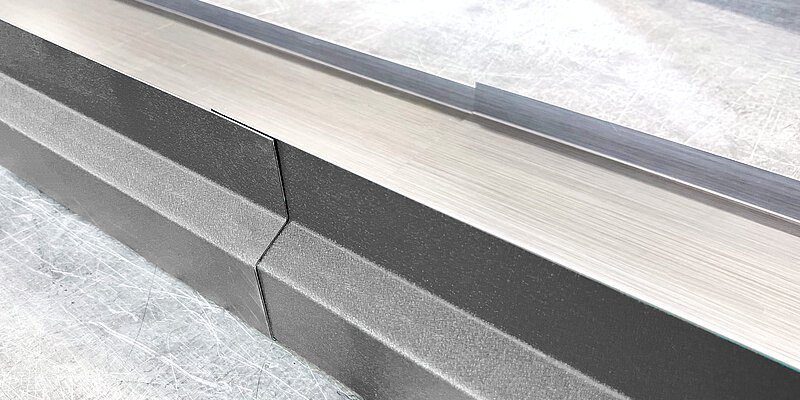

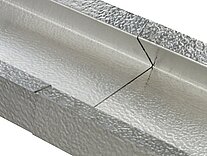

Tapered parts

If the working length of the XL-Center is not long enough, tapered bent profiles can be connected to each other.

- Perfectly matching tapered profiles

- Tapered side selectable with one mouse-click

- No programming effort

- Software calculates blank loading position

- No material bracing. Entire backgauge moves to a tapered position

Bending complex parts

RAS has designed XL-Center with maximum free space in front of the folding beams and has also patented this aspect. The extremely large free area of 300 degrees creates room for the most complex part geometries.

- Umlimited part design flexibility

- Folding beam already inside the part for the next bend

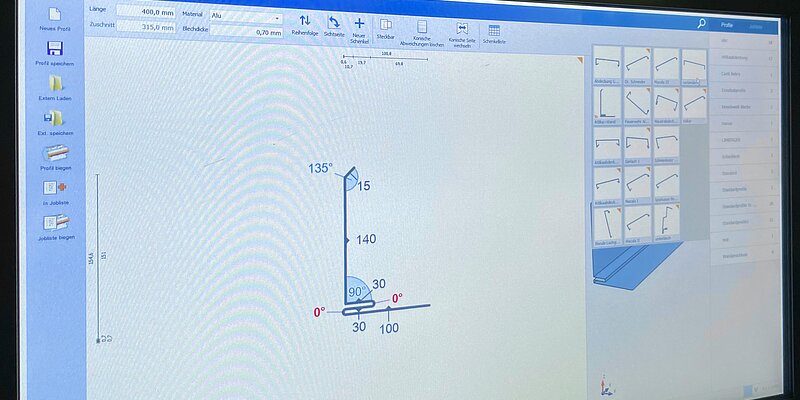

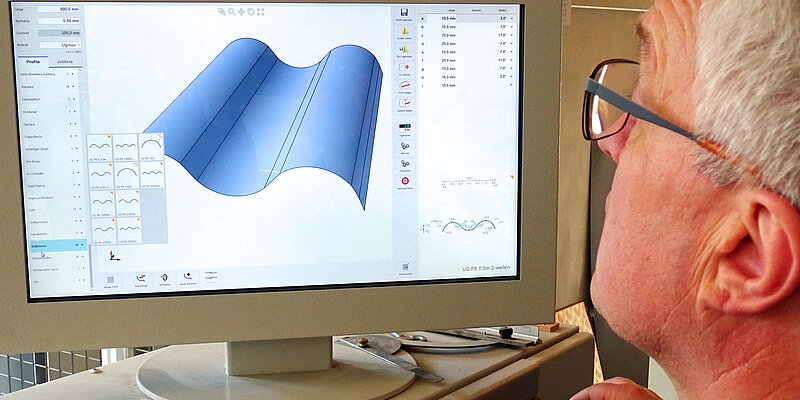

Automatic part programming

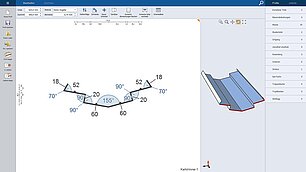

The operator draws the profile of the touch monitor or in the office using the Office software. The Bendex software automatically programs the part and suggests the optimum bending strategy. The software simulates the entire program cycle in either a 2D or 3D view.

- Dimensions and angles clearly visible even on complex profiles

- Automatic programming of the bending sequence with a single mouse-click

- Including tapered part calculation

- No bending expertise required

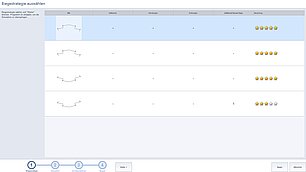

- Software suggests the best bending strategy with a 5-star ranking

- 2D or 3D bending sequence simulation

- Visualizing possible collisions

- With Office-Software: Programming and feasibility study in the office

Program features

The unique and powerful Bendex software automatically programs the parts. Its enormous fetaure list increases the throughput and productivity of the machine many times over.

- Material and thickness selection (Auto angle correction)

- Hems: close, open, drop-shape

- Radius bending

- Calculation of tapered parts

- Unfolded blank calculation (inside dimensions)

- Profile archieve, Joblists, Similar part search feature

- Order processing with Bendex software (Professional / Ultimate)

- Online-Support via TeamViewer

- Online Software Updates

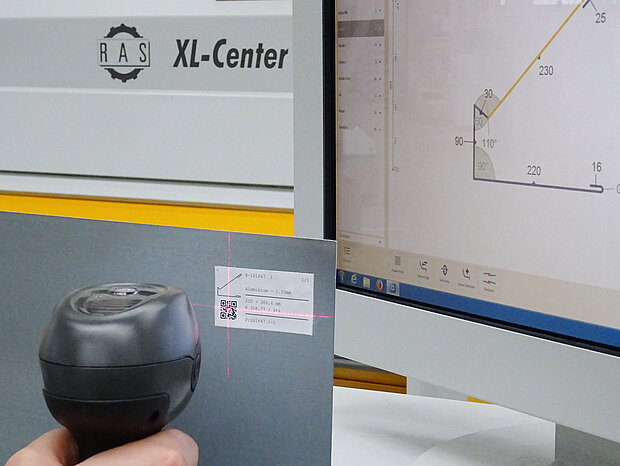

Loading programs with a Matrix Code

Process optimization is so easy! While cutting just stick a QR code on the blank. At the XL-Center you only have to scan the code and the machine automatically loads the part.

- No input errors

- Fast and flexible program change

- Do n ot loose track at any time

- Blanks do not need to be processed immediately

|

RAS 63.30 |

|---|---|

| Folding length | 3200 mm / 126" |

| Material thickness max (400 N/mm²) | 1.5 mm |

| Free space in front of the beams | 300° |

| Grippers | yes |

| Bending tapered parts | yes |

| Programming | automatic |

| Machine dimensions (normal setup) | 5400 x 3700 mm / 213" x 145" |

| Machine dimensions (compact setup, higher fences) | 3850 x 3700 mm / 152" x 145" |

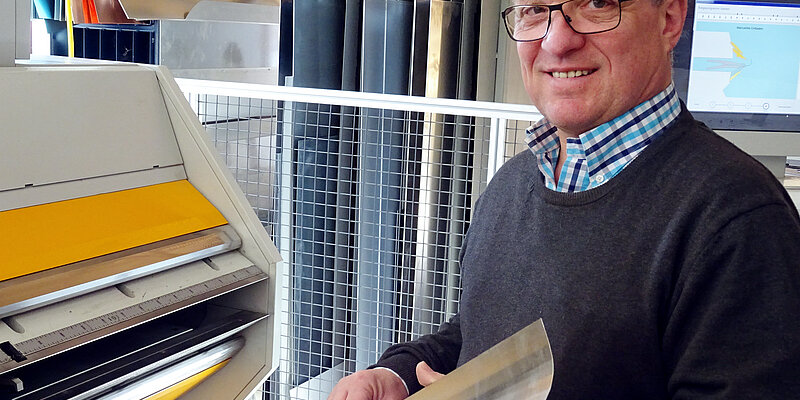

Blechnerei Johannes Schwär from the Black Forest is a dynamically growing craft business. This growth is no accident. Rather, Johannes Schwär is always thinking one step ahead and wants to be equipped with its decisions for current and future tasks. The investment in a RAS XL Center with UpDown bending technology demonstrates the company's progressive thinking.

After the decision to modernize the machinery had been made, the only remaining question for Johannes and Thomas Binder was whether to re-invest in a traditional metal folder with only upward bending. In the end, the two roofing professionals decided in favor of a state-of-the-art RAS XL center with UpDown bending technology. "The XL-Center more than compensates the higher investment costs with its additional benefits," summarize the two entrepreneurs.

For two generations, Begoin GmbH has been a synonym for solid and reliable roofing. Through the precision processing of high-quality materials, the Bad Hersfeld based company has earned a high reputation in the regional market. Three RAS machines assist in meeting the company's performance promises in terms of quality and on-time delivery. Cuttings is done on a RAS SMARTcut swing beam shear. For bending, a RAS TURBObend plus as well as the UpDown folder RAS XL-Center are used.

When automatically bending a roof ridge profile, the RAS XL-Center UpDown bending center shows all its skills. There are already embosses in the sheet for later fastenings. Therefore, the upper beam must gently clamp the sheet so that the embosses are not damaged during bending. The Bendex software automatically programs the bending sequence based on the drawn profile.

Stefan Bern is a roofing and façade specialist for demanding residential buildings. With a team of 30 employees, the company produces all metal parts in their workshop. Their own skilled workers assemble the profiles on large private properties in the area. With the RAS XL-Center, the company has significantly increased its efficiency and bending speed.

Roofer Leib reports on their Website: "As a result of the growing demands of modern architecture, ever more complex metal profiles are required. We can produce them now efficiently and precisely by the purchase of a new XL bending center from RAS. The required profiles can be designed directly in the office and sent to the machine. The machine geometry allows the metal to be folded in two directions, which saves expensive material handling time."

When Carl Schmidt began looking for a new metal folding machine to produce profiles for commercial construction, he took an unusual route. Instead of visiting trade shows or different manufacturers, he started watching YouTube clips of the different manufacturers. He was so impressed by the RAS XL-Center that he decided to place an order without ever seeing the machine live. What might seem to some like a rushed action was, in reality, carefully thought through.

Manfred Baldauf and his wife first saw the RAS XL-Center at the DACH+HOLZ (Roof+Wood) show and immediately fell in love with the machine. The roofing and tinsmith company from Doren (Austria) works on both residential housing construction and with commercial developers and builders. The capability to form unique and unusual facades has most impressed Manfred Baldauf and the RAS XL-Center can bend exactly these profiles with whimsical shapes, radii and hems.

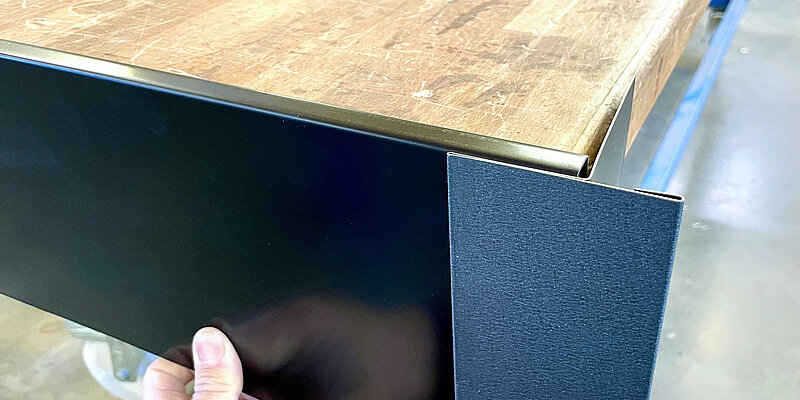

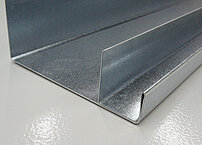

Bending double material

By adding manual bending sequences, the variety of possible profiles can be significantly increased. The software also calculates like the right upper beam clamping dimension when clamping on and bending of double material.

- Possible with thin materials

- Increased rigidity of the parts

- Edge protection

![[Translate to English:] Geschäftsführer Johannes Schwär und Mitarbeiter Timo Schweizer](/fileadmin/_processed_/6/7/csm_Schwaer_Schweizer_b2b576dc94.jpg)

![[Translate to English:] XL-Center bei Blechnerei Johannes Schwär in St. Peter](/fileadmin/_processed_/b/0/csm_XL_beiSchwaer_23b5294faf.jpg)