Quick and easy forming

and closing of long seams

on air ducts

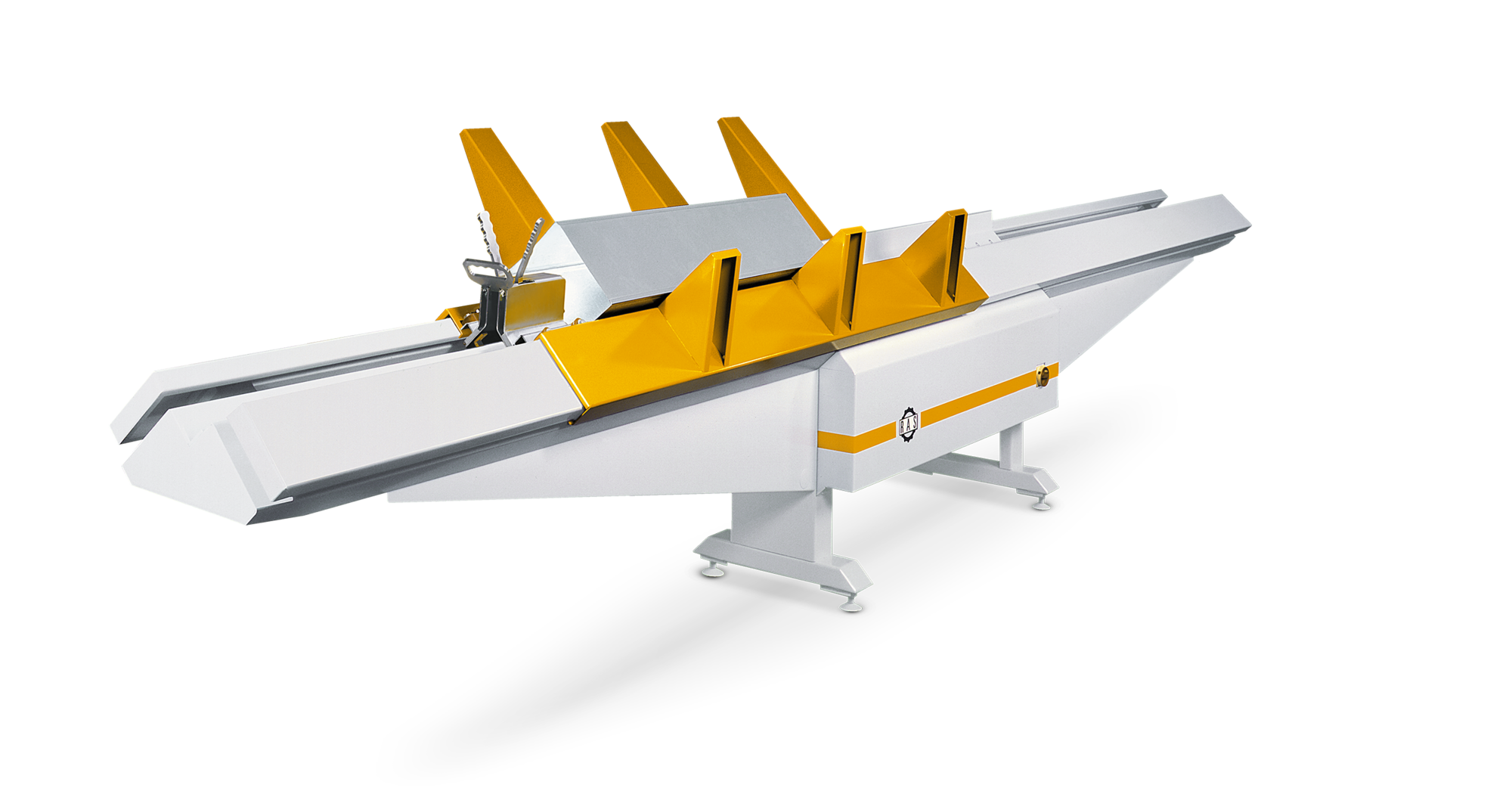

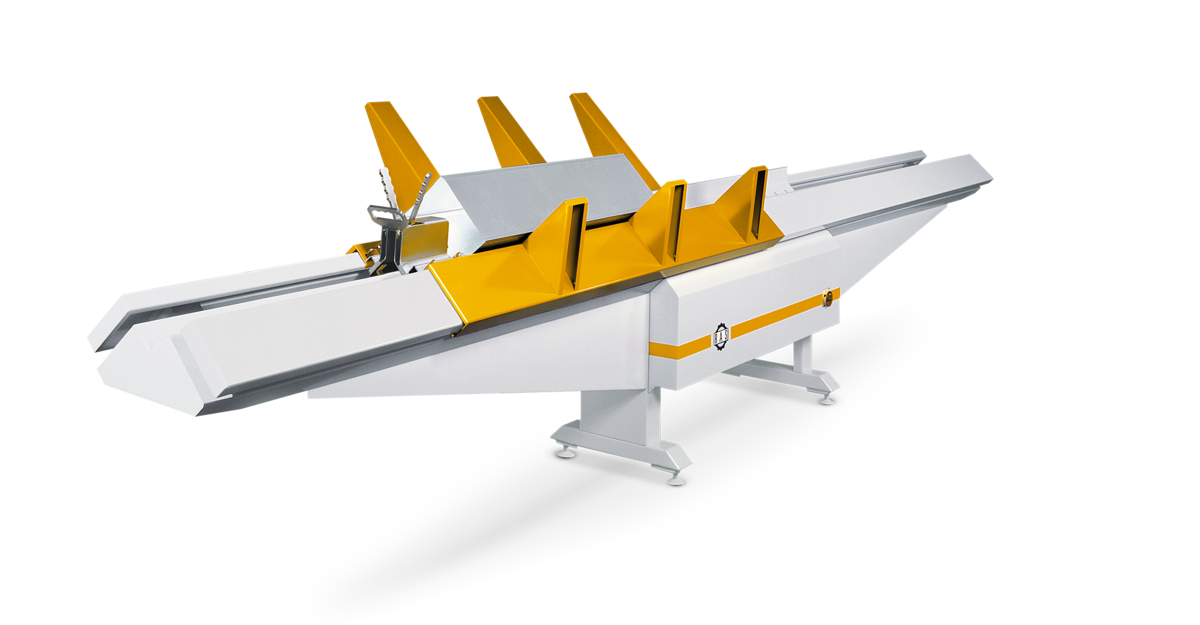

DuctZipper-V Ducting machines

Machine highlights

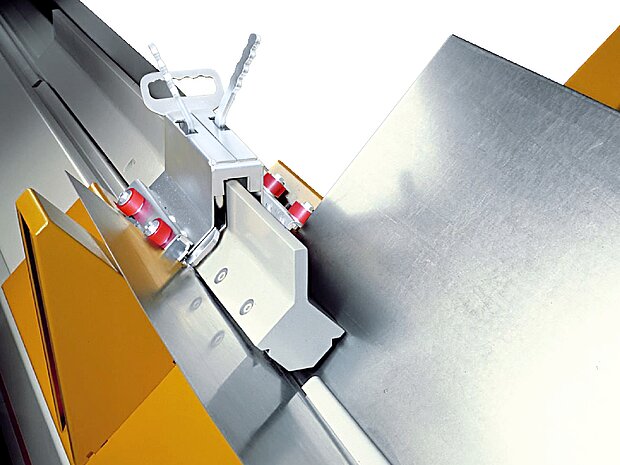

- Due to the V-shape sheets slide by gravity to the connection point

- Ideal machine for small and medium sized air ducts

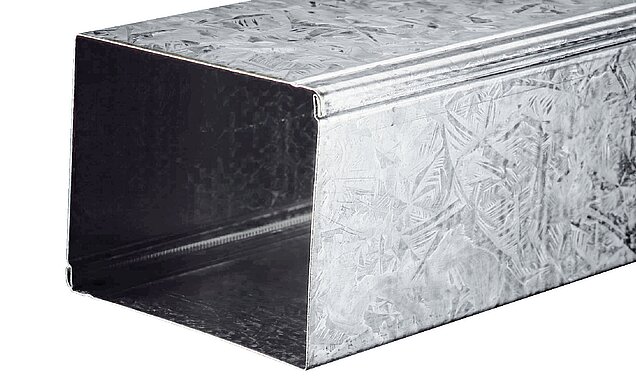

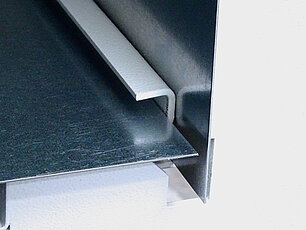

- Very tight seam joint for demanding applications

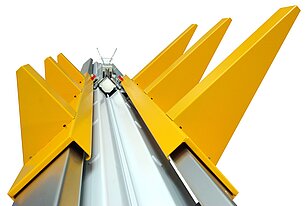

- SealJet seals the joint for extreme energy efficiency requirements

- AutoPilot ensures a simultaneous start of the seam on both ends

- The duct support system holds the weight of the duct

- If there are several seams the support system becomes a transport system

- Ducts may return on the support system back to the entry side

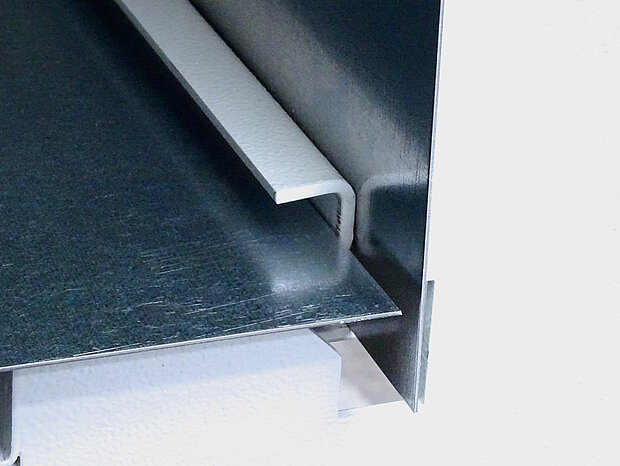

- Improved seam quality due to extended guiding rail

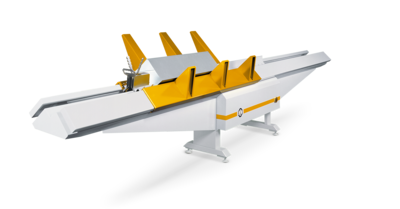

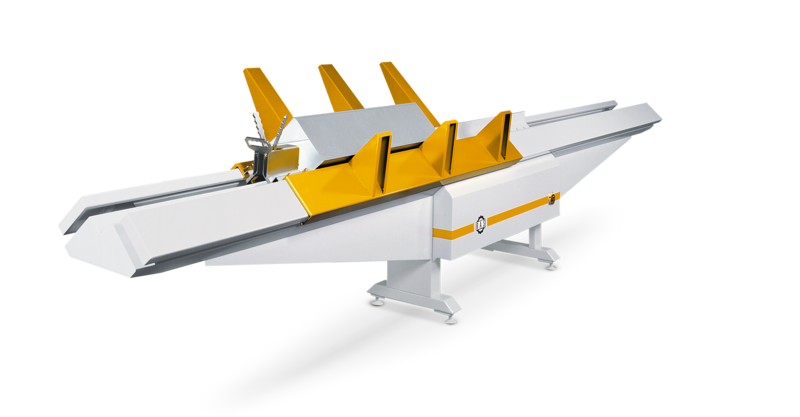

Support system guides the duct through the DuctZipper

The support system with its three short and three long arms supports small and medium size air ducts ideally. The support system moves through the machine connected to the AutoPilot starting from the run-in to the run-out side.

- The support system becomes a transport unit, if there are several seams on one duct

- Ducts may return on the support system back to the entry side

Improved seaming accuracy

As the U-shaped rail at the run-in side has been extended up to the forming rolls the duct will be guided to the very end. This improves the seaming quality on the DuctZipper in L-shape especially at the outlet side of the duct, which also results in a reduced distortion of the duct cross-section.

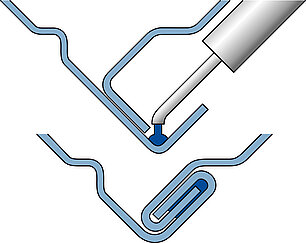

Super tight air ducts

The SealJet additionally seals the seam joint during the run.

- Easy, fast, efficient and clean sealing of the seam joint

- Sensors starts and stop the injection process

- No additional operation steps required

- Recommended sealant: Mez-Bluemastic-Gel

- A container (25 kg) sufficient for approx. 18,000 meters seaming length

- Sealant is temperature resistant from -30°C to +160°C

- Sealant provides corrosion protection (corrosion degree 0).

- Sealant meets the latest hygiene requirements

- SealJet can be retrofitted to existing machines