Description

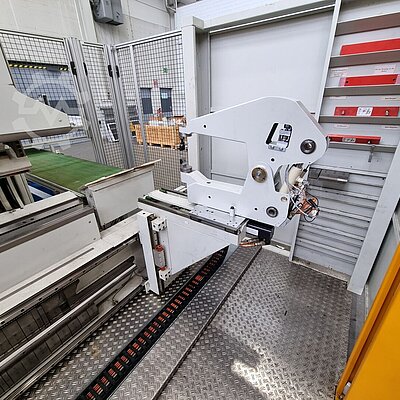

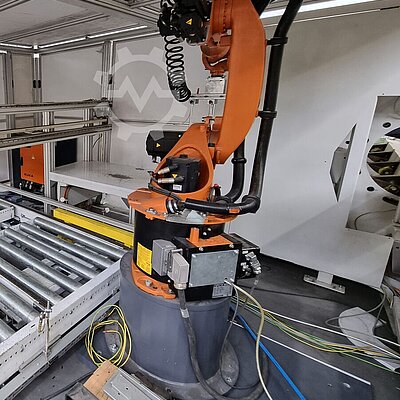

This high-quality used RAS MiniBendCenter 79.05 offers you proven quality at an attractive price and is available directly from the manufacturer. It is a fully automatic bending center specifically designed for the efficient processing of small parts. It comes with a manufacturer's warranty, maintenance included, and the latest software version. With advanced technology such as automatic sheet thickness adjustment, an intelligent loading robot, and a powerful control system, it optimizes your production and reduces costs. Benefit from high flexibility and fast amortization through automated processes and versatile configuration.

- Fully Automatic Bending Center—ideal for precise small part processing

- Directly from the manufacturer—with warranty, maintenance, and the latest software

- Modern equipment—automatic sheet thickness adjustment, panel scanner & intelligent loading robot

- Powerful technology—servo motor-controlled manipulator & automatic tool changer

- Efficient production—integrated pallet station & RAS CAM-Office software including SolidWorks

Automated processes for fast production

production changes and lower costs

Technical data

| Board length: | 50–600 mm |

| Board width: | 40–600 mm |

| Sheet thickness max. (400 N/mm²) depending on tool: | 3,0 mm |

| Upper cheek stroke max: | 500 mm |

| Smallest leg height Standard value depends on tool: | 5 mm x s |

| Maximum leg height: | 127 mm |

| Weight of bending cell: | 10 tons |

| Weight of cladding and electrics: | ca. 2027 kg |

| Weight of machine elements: | ca. 945 kg |

| Motor operation: | 400V, 50/60 Hz, 3-Ph |

| Year of construction: | 2015 |

| Condition: | refurbished—good used condition |

| Location: | Sindelfingen |

Bending cell:

- Automatic sheet thickness adjustment

- Automatic tool clamping

- Blank scanner

Main manipulator:

- 3 servomotors for X,Y,Z

- 1 servo motor for lower rotary axis + separate drive for rotary axis

- Double sheet detection

Tool changer:

- 3 servomotors for X,Y,Z

- 1 pneum. Swivel drive for rotary axis

- Tool gripper

- Tool magazine on 2 levels

- Automatic tool clamping in the tool magazine

Cladding:

- Bending cell front and rear

Movable control panel:

- 18" Touch & More control unit

Pallet station:

- Roller conveyors and heavy-duty chain conveyors

- 1 space for new pallets (parts that are being processed)

- 1 space for "pallet in process"

- 2 spaces for finished pallets (empty or with remaining quantity)

Additional equipment:

- Intelligent charging robot

- Combined camera-scanner system

- Analysis software

- Transfer table, Sauerfeld (52x9mm) suction cup series (7x20mm)

- Conveyor curve belt with 6 connection stations

- Cladding finished part output

- Complete tool set

- RAS CAM-Office software incl. SolidWorks license and maintenance contract for 2 years