The industry 4.0 standard is achieved in

combination with a RAS bending machine and

one of the Bendex Enterprise Suite solutions

RAS machines software

RAS machines software

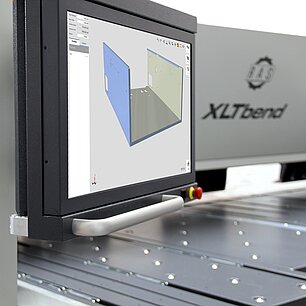

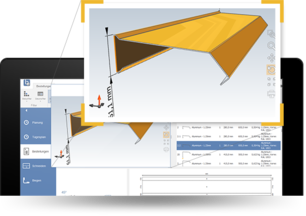

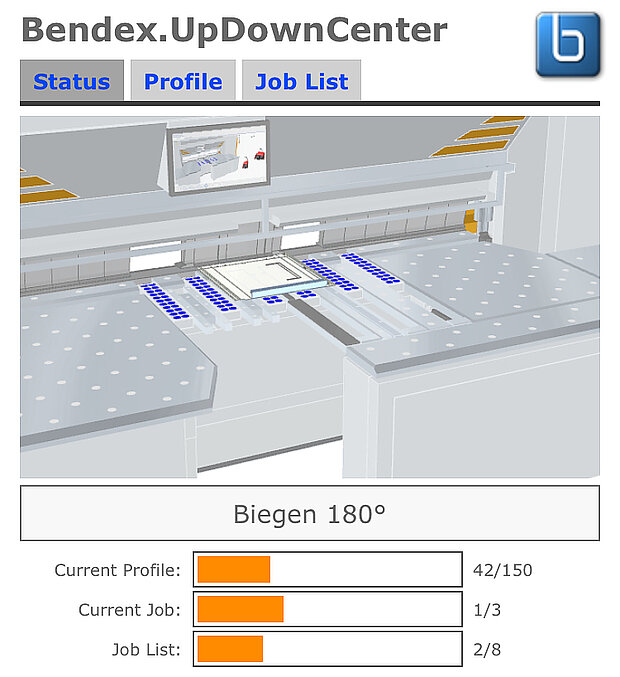

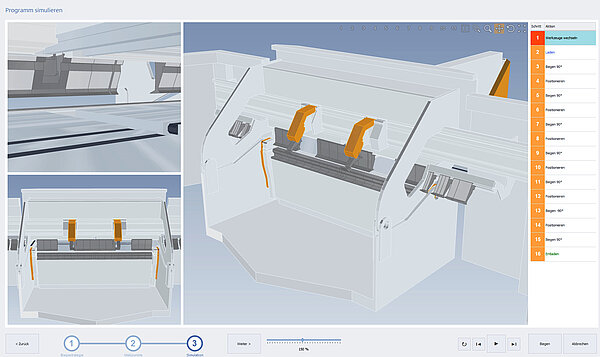

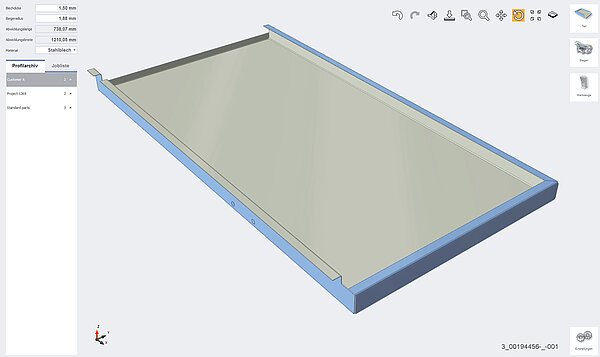

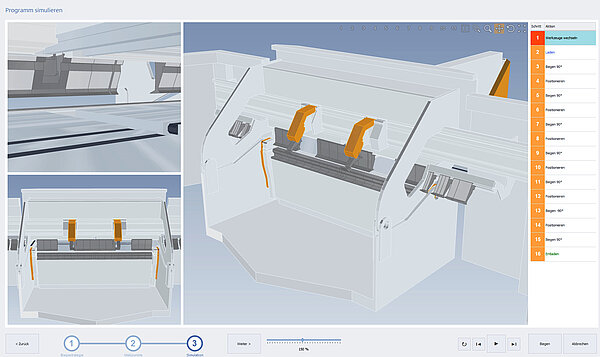

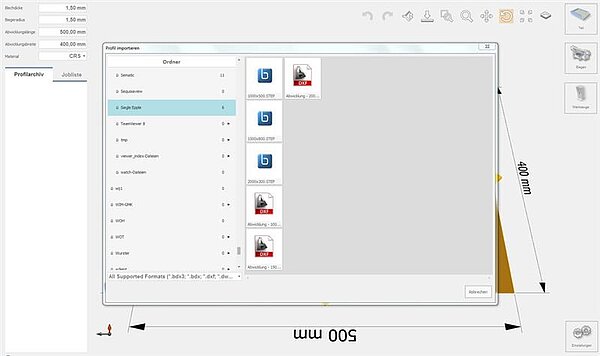

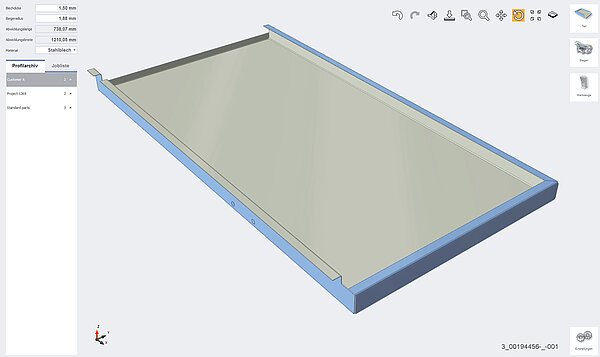

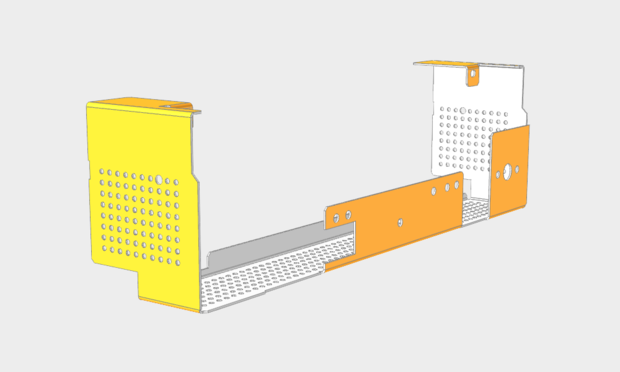

With the RAS machine controls powered by Bendex, all geometries of a bending part can be easily imported into the machine. The control automatically generates bending program suggestions, detects tool collisions, and visualizes the process in 3D. Through the integration of CAD data and an intuitive user interface, the system enables fast and efficient programming, reduces communication efforts, and ensures seamless production.

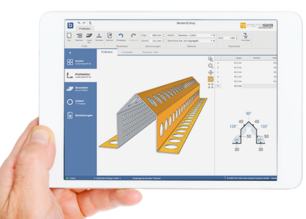

- Capture bent parts easier and faster than ever before

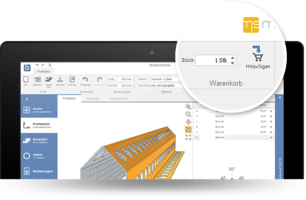

- Use Bendex.store in the office or mobile on your tablet PC

- Manage your construction projects

- Produce them with high quality manufacturing drawings

- Increase your delivery readiness and production quality

- Reduce misproductions and complaints

- Export production drawings as PDF

- Transfer the production data directly to the production machines

Bendex Software

Within the unique Bendex platform, two types of market-leading and powerful software solutions have been developed. Both software packages together provide fully integrated solutions for order acceptances, order processing and production:

- Bendex Machine and Office Software for automatic programming of bending sequences on RAS metal folding machines

- Bendex Enterprise Software for sales and production of bending parts incl. accessories

Machine & Office Software

These capabilities are exclusively available for RAS metal folding machines. The Bendex software automatically programs the bending sequence based on the drawn or imported part geometries. The full integration and digital consistency entitled RAS to an exclusive “powered by Bendex” technology partner. You can read about more details of this integration on the site Bendex Partner Program.

Versions of the Bendex Machine and Office Software are currently available for the following RAS metal folding machines:

- Multibend-Center (Office)

- UpDownCenter-2 (Machine and office)

- MEGAbend (Machine and office)

- XLTbend (Machine and office)

- FLEXI2bend (Machine and office)

- TURBO2plus (Machine and office)

- ProfileCenter (Machine and office)

- XXL-Center (Machine and office)

- XL-Center (Machine and office)

By purchasing a software update contract, the customer can benefit from ongoing further developments of the software and the additional features.

Bendex Enterprise Software

The Bendex Enterprise Software is divided into modules, allowing the user to assemble their individual set of features. Depending on the complexity and customer-specific adjustments, two version levels are available:

- Bendex Enterprise Professional

- Bendex Enterprise Ultimate

Capabilities of Bendex Enterprise Professional

- Fast and error-free capture of parts in the office or on the mobile device

- Profiles with tapered flanges, holes and notches

- Solution for in-house production/assembly or for the parts to be sold

- Automatically generates quotes 24/7 and calculates sales prices

- Customers can order 24 hours a day

- Customer loyalty through innovative service

- Reduces order processing time to a minimum

- Eliminates unnecessary queries to the customer or to the company's own construction crews

- Prepares production documents in a standardized format

- Material management of all available materials and coatings

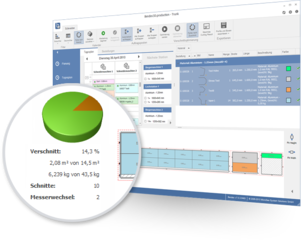

- Automatic calculation of material demand incl. waste optimization

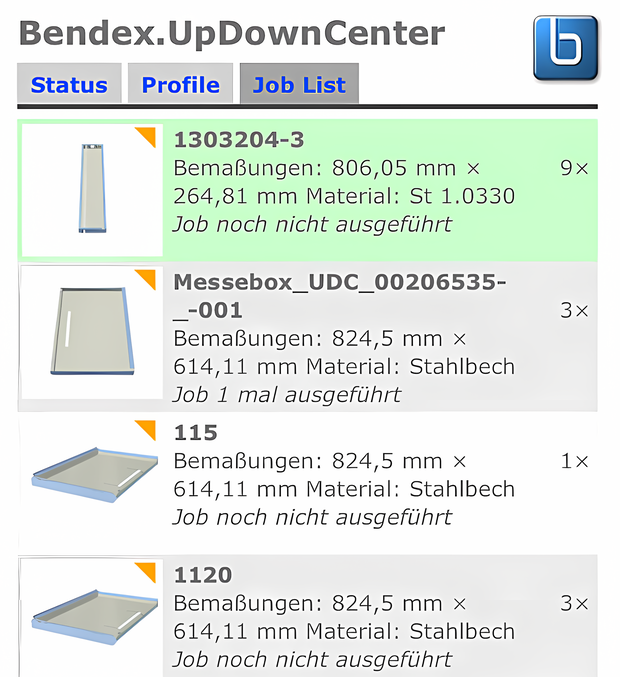

- Shows order overviews incl. search and filter functions

- Planning views for time intervals, machines and jobs

- Fully automatic programming of RAS machines folding machines

Bendex Enterprise Professional offers a total solution for producers, distributors, dealers and assemblers of metal profiles, bent parts and roll-formed components including accessories.

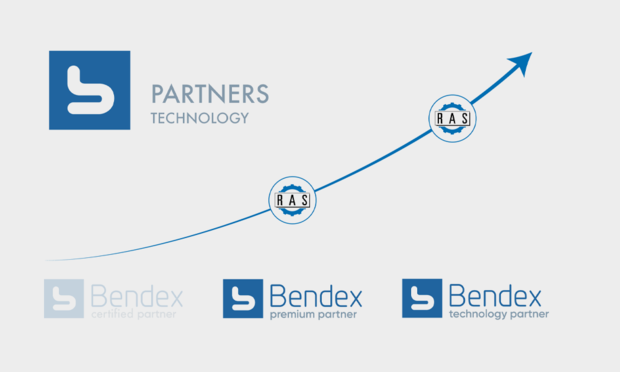

Bendex Partner Program

Bendex software has been established worldwide as a platform for sheet metal production addressing the company organization and the machine-related environment. A partner program shows the intensity of the cooperation in sales and technology. RAS has reached the highest levels of cooperation. The following logos illustrate the quality of the software solutions.

Premium Partner:

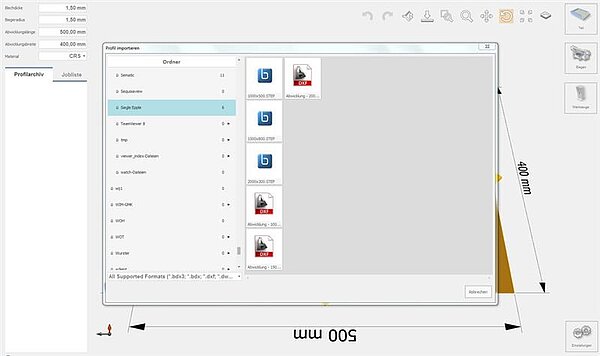

As a Premium Partner, RAS offers the most powerful software integrations. This starts with the import of part geometries in countless data formats (STEP, dxf, dwg, geo, etc) and the analysis, preparation and import of the CAD bending part data.

It is also possible to export the part geometries in the most common data formats (STEP, dxf, dwg, geo, etc).

Technology Partner:

RAS is the only manufacturer of sheet metal working machines who has reached the "Technology Partner" level. This means that the Bendex runs as the control software on RAS folding machines. The logo "powered by Bendex" on the machine indicates this complete integration.

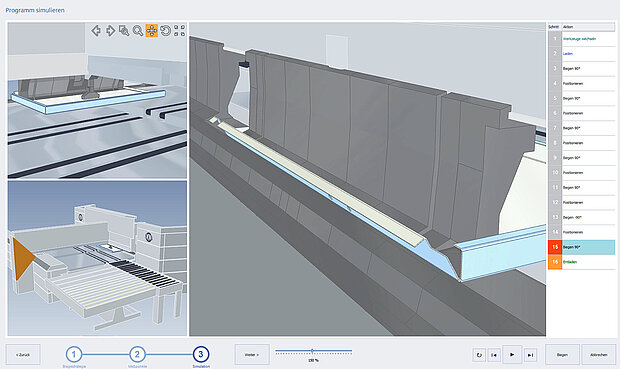

The full integration includes for example:

- Machine control with Bendex software

- Office programming with Bendex Office software

- Automatic programming of the bending sequences

- Visualization of different bending alternatives with a 5-star rating

- Simulation of the bending sequence in a 3D view already in the Office Software

- Bidirectional communication between machine and office ensures that the bending sequences are based on current machine data. For instance, the actual travel distances of the axes or the tools currently available at the machine are imported and incorporated for programming the bending sequences.

- During the automatic programming of the bending sequence, material tables consider the specifications of different materials when bending different sheet thicknesses, leg lengths and angles.

- Creation of individual part catalogs.

- Sending of bending programs or job lists with job sequences from the office to the machine.

- With a data model of the machine, the Bendex software considers the impact of the machine deformation on the bending result.

- The tools are stored in the software with a wide range of metadata. Thus, the Bendex software knows, for example, the maximum free space around a tool and its bending capacity.

- Calculation of real cycle times for quotations, including handling times for loading, turning, flipping and unloading of bent parts with different sizes and weights.

- Service modules: Analysis of the operating times of individual axes and indication of service points.

- Application profile: Stainless steel parts often have higher quality requirements than a general sheet metal components. By selecting a application profile, you can specify whether a tool setup should be with gaps between the tools or without gaps. The gap-free set-up results in visually perfect stainless steel parts, but may lead to longer setup and bending times.

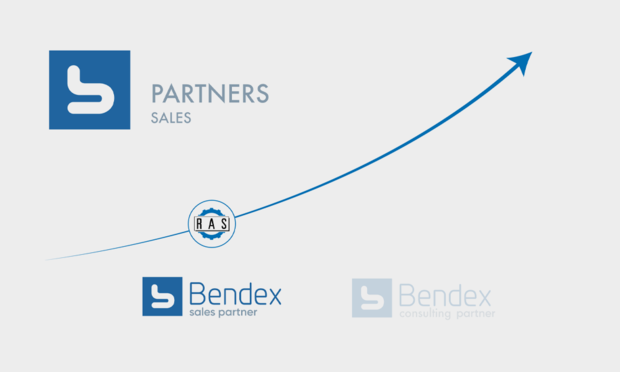

Sales Partner:

As a Sales Partner, RAS has trained sales personnel and can support customers on any of the Bendex software products. As a Sales Partner, RAS distributes, installs and trains Bendex solutions. The product range supported by RAS includes:

- Bendex Machine Software for RAS metal folding machines

- Bendex Office Software for RAS metal folding machines

- Bendex Update Contracts for new features and software updates

- Bendex Professional Enterprise Software

640% more performance

The production of bent parts faces the challenge of manufacturing increasingly smaller batch sizes and highly customized products quickly and efficiently. With Bendex software, this transformation can be successfully managed: it optimizes not only production speed but also the entire value chain, from planning to execution.

- 640% more performance: Through intelligent automation

- Fast programming: Bending programs in under a minute

- Error reduction: Optimized value chain

- 3D simulation: Visualize and plan bending processes

- More efficient small batches: Faster adaptation to custom orders

- Fewer meetings: 75% fewer coordination efforts

- Minimized processes: Faster feasibility checks and calculations

Bendex gets us to our goal

10 times faster—less effort, more precision

Does an increase in performance of 640% sound attractive? But how can you reach such a level? Those, who already use state-of-the-art production systems, will not achieve this thrust by just targeting for faster production cycles. For an increase of the overall efficiency, it is not sufficient setting on faster axes movements and machine cycles.

The challenges are quite different. Large batch sizes are no longer reality for most companies. The customer always wants more individual products. Individualization does not only apply to the individual manufacturers, but more and more arrives in serial production. Unique product features increase the number of variants and reduce the batch sizes. Jobs are coming in smaller quantities. After having bent just some parts the machines need be setup for the job. The ratio between production time and set-up time is becoming increasingly unfavorable.

The work steps ahead of production, on the other hand, remain the same. However, a much more frequent passage through the indirect processes leads to a remarkable increased effort. A larger number of parts need to be analyzed for feasibility, partially redesigned and approved by the customer. After all production and design aspects are clear, the variants must be calculated and offered. Once the order has been received, machine programs need to be generated and setup plans need to be written.

The solution: Bendex software for greater efficiency

The effort required for indirect processes is increasing significantly. Therefore, the future goal must be to optimize not just individual production steps, but the entire value chain. Errors must be avoided even in a fast-paced environment, while keeping costs under control. When this is achieved, small batch orders once again become profitable. With Bendex Enterprise Professional, pre-production workflows can be reduced to a minimum.

When bending sheet metal components, the Bendex machine software or Bendex Office Software imports the geometry of the bent part in a variety of file formats and programs the bending process with a single click. While programming used to take, for example, 10 minutes, the Bendex software creates a bending program in under a minute and even allows for a 3D simulation of the bending process. The software's algorithms incorporate the expert knowledge of hundreds of programmers. This not only speeds up programming by a factor of 10 but, if the Office software is already used in the design phase, designers can check the feasibility of their new components without specialized bending knowledge—long before the first sheet is produced.

Results: faster processes and greater efficiency

Additional meetings and coordination between design, production planning, and manufacturing are reduced by 75%. These accelerations in upstream processes, combined with efficient tool changes and short setup times, create the efficiency gains that companies are striving for today.