640% more performance

The production of bent parts faces the challenge of manufacturing increasingly smaller batch sizes and highly customized products quickly and efficiently. With Bendex software, this transformation can be successfully managed: it optimizes not only production speed but also the entire value chain, from planning to execution.

- 640% more performance: Through intelligent automation

- Fast programming: Bending programs in under a minute

- Error reduction: Optimized value chain

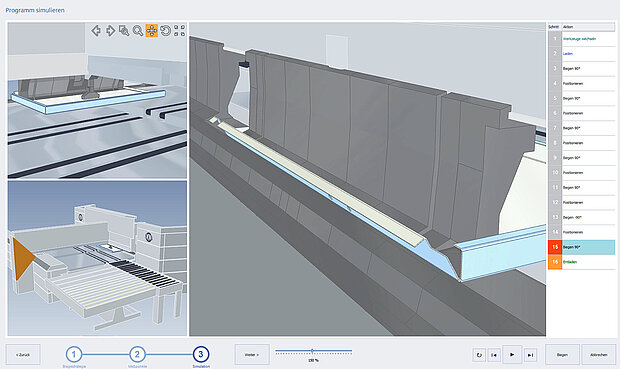

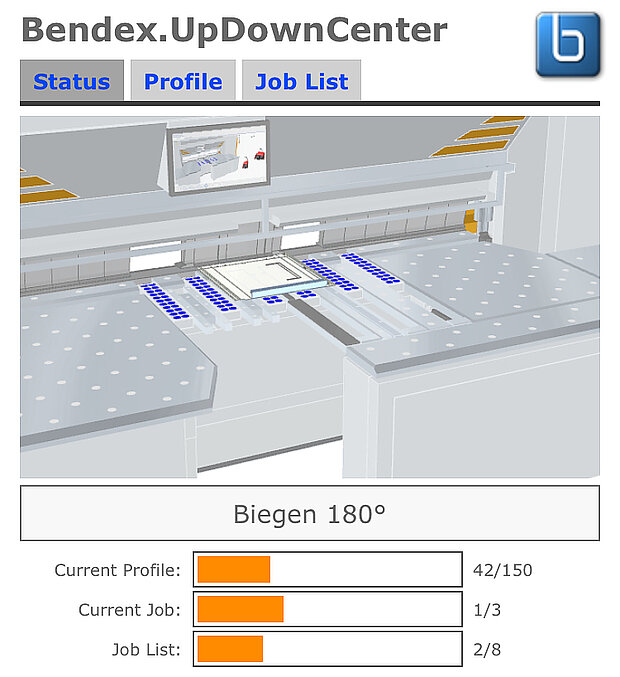

- 3D simulation: Visualize and plan bending processes

- More efficient small batches: Faster adaptation to custom orders

- Fewer meetings: 75% fewer coordination efforts

- Minimized processes: Faster feasibility checks and calculations

Bendex gets us to our goal

10 times faster—less effort, more precision

Does an increase in performance of 640% sound attractive? But how can you reach such a level? Those, who already use state-of-the-art production systems, will not achieve this thrust by just targeting for faster production cycles. For an increase of the overall efficiency, it is not sufficient setting on faster axes movements and machine cycles.

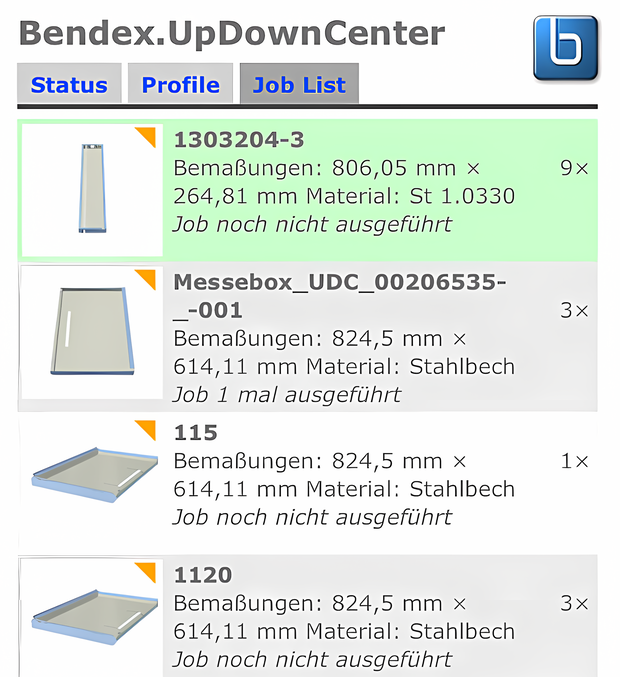

The challenges are quite different. Large batch sizes are no longer reality for most companies. The customer always wants more individual products. Individualization does not only apply to the individual manufacturers, but more and more arrives in serial production. Unique product features increase the number of variants and reduce the batch sizes. Jobs are coming in smaller quantities. After having bent just some parts the machines need be setup for the job. The ratio between production time and set-up time is becoming increasingly unfavorable.

The work steps ahead of production, on the other hand, remain the same. However, a much more frequent passage through the indirect processes leads to a remarkable increased effort. A larger number of parts need to be analyzed for feasibility, partially redesigned and approved by the customer. After all production and design aspects are clear, the variants must be calculated and offered. Once the order has been received, machine programs need to be generated and setup plans need to be written.

The solution: Bendex software for greater efficiency

The effort required for indirect processes is increasing significantly. Therefore, the future goal must be to optimize not just individual production steps, but the entire value chain. Errors must be avoided even in a fast-paced environment, while keeping costs under control. When this is achieved, small batch orders once again become profitable. With Bendex Enterprise Professional, pre-production workflows can be reduced to a minimum.

When bending sheet metal components, the Bendex machine software or Bendex Office Software imports the geometry of the bent part in a variety of file formats and programs the bending process with a single click. While programming used to take, for example, 10 minutes, the Bendex software creates a bending program in under a minute and even allows for a 3D simulation of the bending process. The software's algorithms incorporate the expert knowledge of hundreds of programmers. This not only speeds up programming by a factor of 10 but, if the Office software is already used in the design phase, designers can check the feasibility of their new components without specialized bending knowledge—long before the first sheet is produced.

Results: faster processes and greater efficiency

Additional meetings and coordination between design, production planning, and manufacturing are reduced by 75%. These accelerations in upstream processes, combined with efficient tool changes and short setup times, create the efficiency gains that companies are striving for today.