FLEXI2bend Software 1-click programming

FLEXI2bend Software

1-click programming

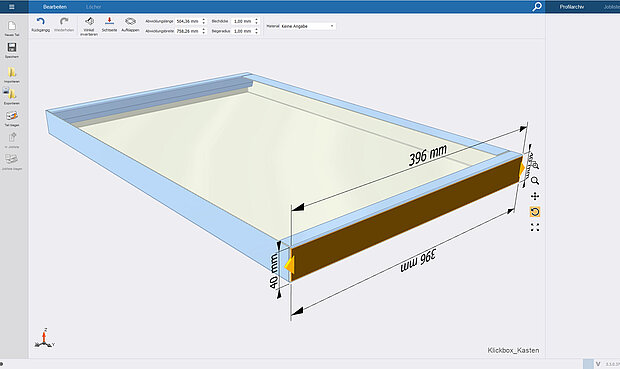

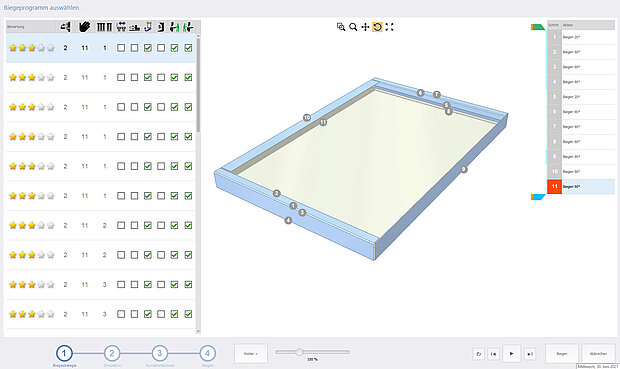

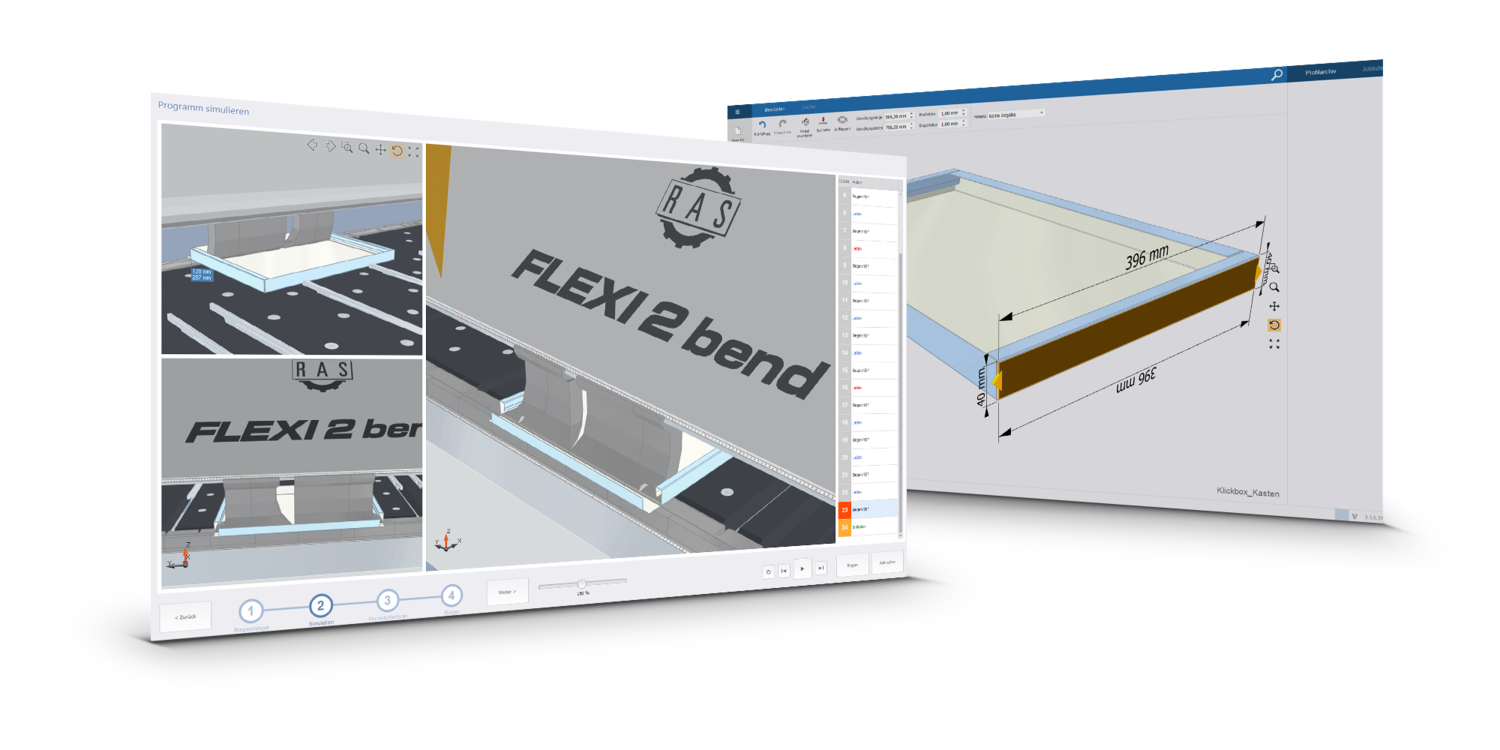

Draw or import a part geometry

- Draw a profile on the monitor

- Add flanges to the 3D profile

- Import a STEP file (alternatively: DXF, GEO) with the part geometry

- The software analyzes the STEP file and automatically generates a 3D model. For DXF files, the programmer has to add to the bend angle.

- Overbend angles for springback compensation are added from material tables.

Software versions

Have you signed a software update agreement?

This allows you to update your Machine and Office Software to the next level.

- Includes free Machine software updates

- Includes free Office software updates

- Machine software and Office software versions must match

- For updates of additionally purchased Office licenses, the update packages for subsequent licenses are required

- Online connection to the PC must be available

What do I need to do?

Please contact RAS. After checking the data, we will contact you. We need the following information:

- Address

- Contact person with Email and Phone

- Machine number

Bugfix: Virtual bend lines

- Maintenance update

- New language files implemented

- Optimized tool change position for folding beam

- Optimized tool change position for upper beam

- New file manager

- Bending with Parameter (BWP)

- Adjustment of default firewall rule

- Bugfix CAD export (IGES)

- Improved usability for tool position identification

- Bugfix material tables when loading bending parts

- Optimization of virtual bending lines

- Parameterized performance of strategy calculation

- Parameterized weighting of central bending

- Maintenance update

- Bugfix: import profile folders

- New language files implemented

- New folding beam tools implemented

- Default tool set for initial installation

- Image file machine status information

- Reduction of the user instruction “Hide holes...”

- Bugfix: Animation SnapTools

- New language files implemented

- Bendex Office show machine archive

- Display for tools with plastic insert

- General optimizations of strategies with hems

- Text info box implemented

- bending program entry supports separated hems

- Upper beam tool change position can be parameterized

- New tools

- Language files implemented

- Error when restarting Bendex with corrupt bending part fixed

- CADImporter “Missing flange” optimized

- “Pendulum parameter handling” error fixed

- New language files implemented

- Segment-orientated radius view

- DownTools optimised

- Language files implemented

- Flat sheet development inconsistencies revised

- Preview of already calculated strategies

- Abort behaviour of strategy determination optimised

- User-friendliness of virtual bending lines optimised

- Collision analysis optimised

- Bendingpart alignment CAD import optimised

- New language files implemented

- Bug fix tool display

- New language files integrated

- Menu option for automatic alignment of boxes during CAD import implemented

- Virtual bending line optimization

- Visual optimizations

- Offset input in the hem dialog has been removed

- Better consideration of the collision consideration for leading tools

- Slider for speed setting in simulation implemented

- VBL (Virtual Bending Lines) implemented, for creating bending lines that cannot be constructed

- The input option for the offset in the "Envelope - teardrop hem" dialog has been implemented via the "MaY-Press Offset" in the correction dialog

- Display of the radius tools was optimized

- Parts implemented with tabs aligned to the base surface

- New upper beam tools implemented

- New folding beam tools implemented

- Display of tool widths corrected

- Improved crowning program flow

- "Category" import implemented

- Dialog entry point moved and implemented in the job list

- during STEP import the material thicknesses valid for the machine are requested and not imported if exceeded or fallen short of

- Software detects internal bends

- Configuration selection improved

- Pre-bending and subsequent pressing down with negative flanges

- Expanded metal can be bent with new gauging systems

- GEO import improved incl. base selection

- New languages added

- New upper beam tools implemented

- New folding beam tools implemented

- Manual alignment of the part during STEP import implemented

- Messages of changed radii are automatically adjusted depending on the selected tool

- Improved illustration of holes in part

- Improved bending strategies implemented

- Languages updated

- New upper beam tools implemented

- New folding beam tools implemented

- Improved import of lengths and widths of parts from STEP files and thus optimized calculation of developed blank dimensions

- New design of the evaluation stars

- Tool change menu: Showing of the beam where a tool change will take place. The individual beams are now shown as symbols.

- The calculation of the folding beam crowning has been optimized

- For gauging systems with stop bars for expanded metal, the travel routines of the gauging bar and the upper beam have been optimized in order to prevent possible collisions

- New upper beam tools implemented

- New folding beam tools implemented

- New lower beam tools implemented

- User modes will be transferred when connecting from Office to the machine exists

- Geometries and metadata of the standard FLEXIbend tools (previous model) are also available for the FLEXI2bend

- Max sheet thickness extended to 4.2 mm (equivalent to 8 inches of aluminum)

- Optimized strategies for profiles

- Optimized sequence for upper beam movements

- Mirror-inverted use of the SnapTools possible

- Bending programs can be saved and exported with user mode

- When working from the gauging system side and using the folding beam as a stop, the crowning of the folding beam is set to zero at the beginning of the program

- Allowed protrusion of legs beyond the bending line is calculated based on the sheet thickness

- New folding beam tools implemented

- New upper beam tools implemented

- New lower beam tools implemented

- New gauging systems for 4m model implemented

- Calculation of stop positions optimized

- When bending from the gauging system side, crowning is set to zero

- Allowed protrusion of flanges beyond the bending line is calculated in relation to the sheet thickness

- New folding beam tools implemented

- New upper beam tools implemented

- New lower beam tools implemented

- New gauging systems implemented

- New folding beam tools implemented

- New upper beam tools implemented

- New lower beam tools implemented

- Intervention in the automatically created bending strategies

- Intervention in automatically created programs

- Material tables extended for manual input of crowning values

- Correction of automatic folding beam crowning possible