UpDownCenter-2 Software 1-click programming

UpDownCenter-2 Software

1-click programming

UpDownCenter-2 Software

The UpDownCenter-2 Software has been created specifically for the UpDownCenter-2.

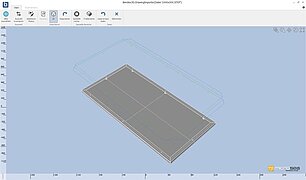

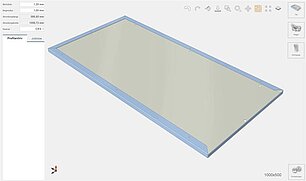

One click programming

- The software programs the bending sequence automatically with a single mouse click!

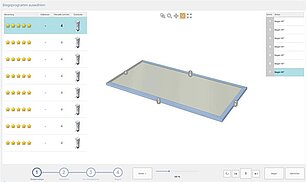

- If there are different folding sequences (fold short side before long side or vice versa), the software shows a ranking of the alternatives.

- The automatically create program also includes handling operations and the tool setup.

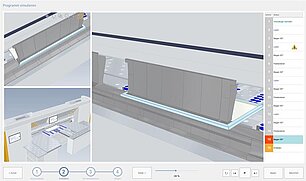

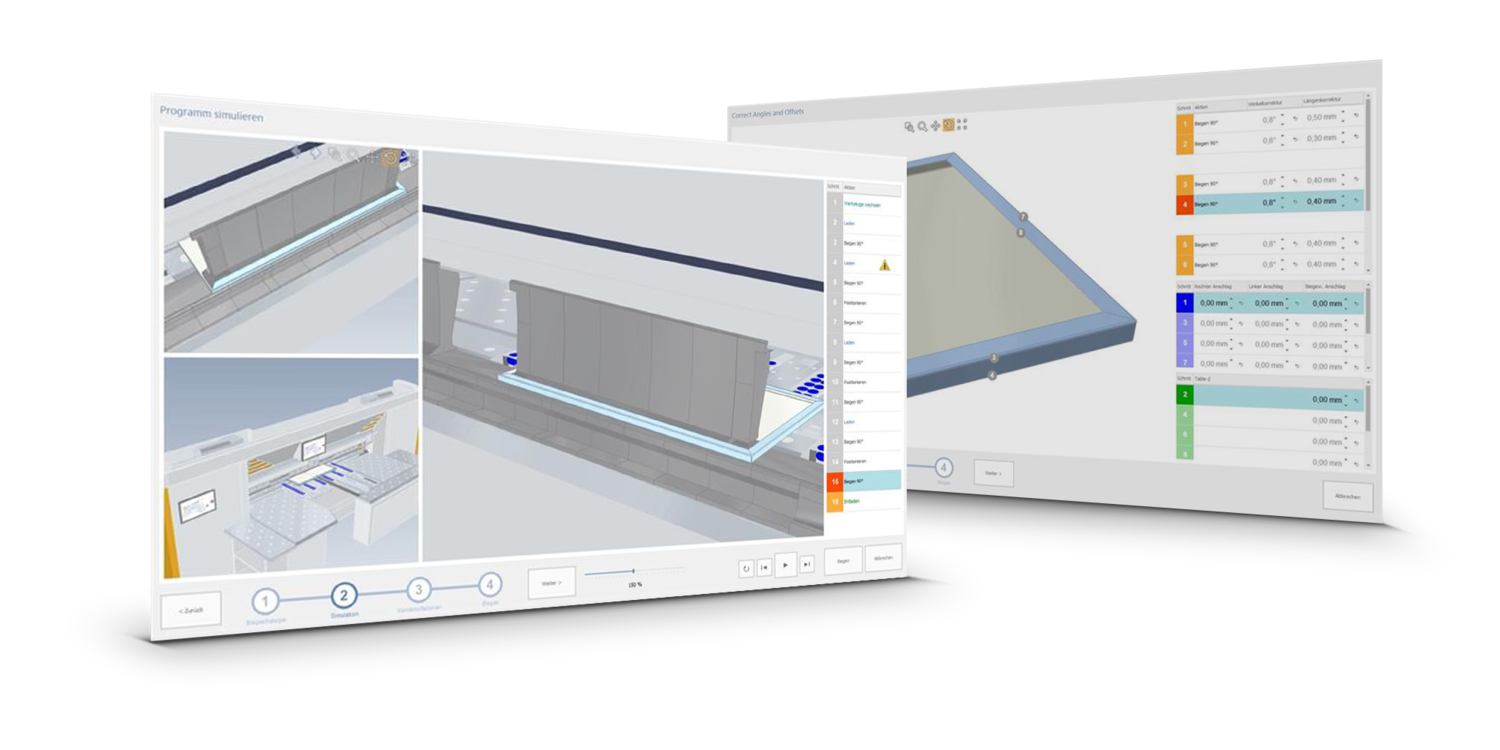

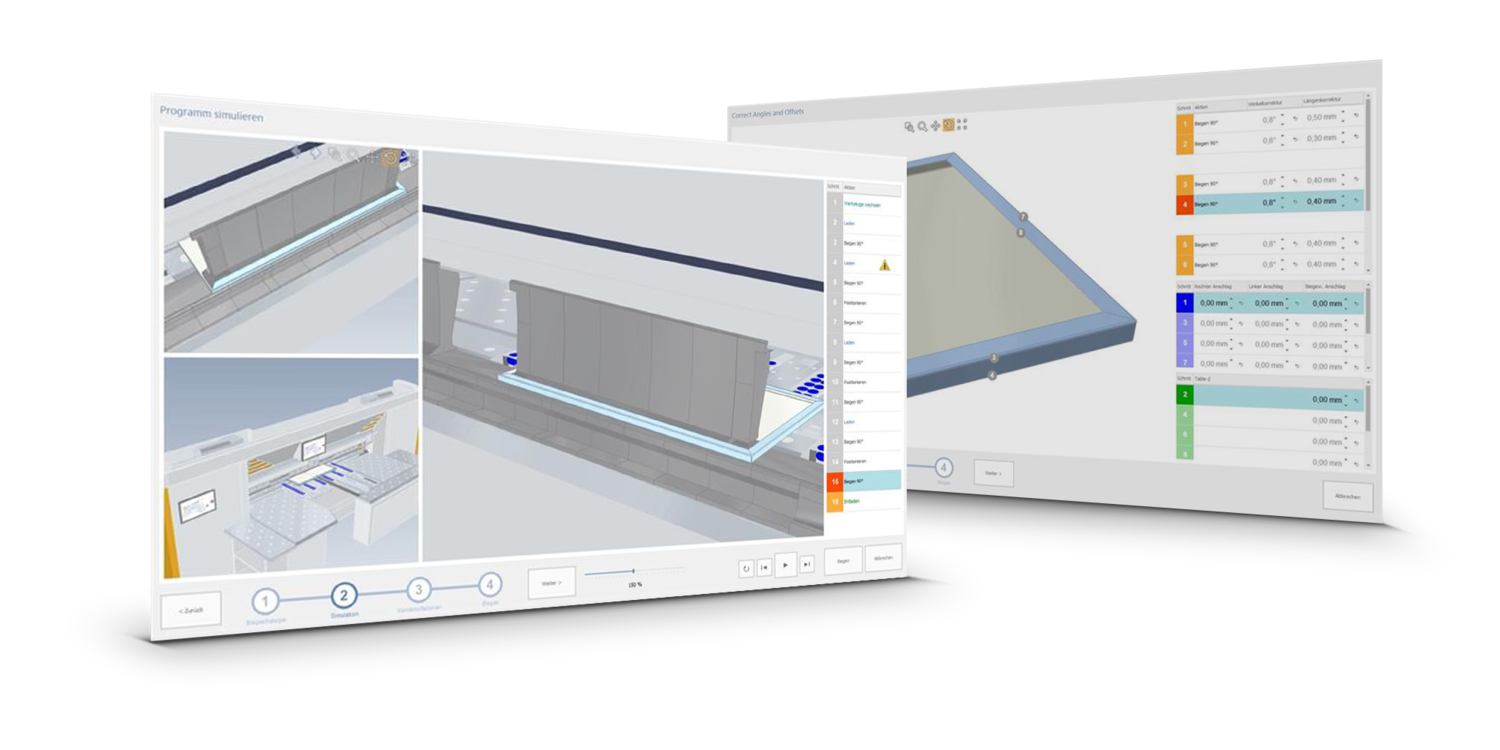

- A 3D program simulation shows in detail how the part will be created.

- The program gets to the machine via network or USB memory stick

Software versions

Have you signed a software update agreement?

This allows you to update your Machine and Office Software to the next level.

- Includes free Machine software updates

- Includes free Office software updates

- Machine software and Office software versions must match

- For updates of additionally purchased Office licenses, the update packages for subsequent licenses are required

- Online connection to the PC must be available

What do I need to do?

Please contact RAS. After checking the data, we will contact you. We need the following information:

- Adress

- Contact person with Email and Phone

- Machine number

- Improvement: stop handling for “obtuse flanges”

- Manual resolution of the side bending position

- Improvement: invalid MaY position (0)

- Improvement: right-angle stop configuration

- Bugfix: Initialization of part numbers (bending beam)

- CADImporter: Optimization of radius length compensation

- Parameterizable weighting of central bending

- Integrated stations support upper beam clearances

- Integrated stations support down tools

- Parameterized performance of strategy calculation

- Significant improvement in strategy calculation performance

- Bugfix: Loss of manual bending instruction when editing text infobox

- Bugfix: Error message “Index out of range”

- Bugfix: Bendex splash screen frozen during machine restart

- Bugfix: VBL – Object reference not set to an instance of an object

- Bugfix: Office machine – Profile archive display

• Bugfix: Virtual bend lines

- Maintenance update

- New language files implemented

- New file manager

- Adjustment of default firewall rule

- Bugfix CAD export (IGES)

- Improved usability for tool position identification

- Bugfix visualization of lower beam tools

- Parameterized performance of strategy calculation

- Parameterized weighting of central bending

- Maintenance update

- Language files implemented

- Collision detection for corner pieces with plastic insert fixed

- NoPower start behaviour standardised

- Bending part collision when changing bending direction rectified

- Language files implemented

- Flat sheet development inconsistencies revised

- Preview of already calculated strategies

- Abort behaviour of strategy determination optimised

- User-friendliness of virtual bending lines optimised

- Collision analysis optimised

- Bendingpart alignment CAD import optimised

- New language files implemented

- New upper beam tools implemented

- New manipulator configuration implemented

- Reactivation of parameters for step bending

- Bug Fix

- New upper beam tools implemented

- New folding beam tools implemented

- New language files integrated

- Menu option for automatic alignment of boxes during CAD import implemented

- Virtual bending lines optimization

- Offset input in the hem dialog has been removed

- New upper beam tools implemented

- New folding beam tools implemented

- Machine model implemented for 500mm high upper beam tools

- Bug Fix, bend radii are no longer shown

- User interface customized

- during STEP import the material thicknesses valid for the machine are requested and not imported if exceeded or fallen short of

- Dialog entry point moved and implemented in the job list

- User modes implemented for different use cases

- Selection for loading options implemented on the outer edges

- Import category implemented in profile archive

- Improved GEO file import for:

- Bend line detection

- Bending radius related to the material thickness

- Recognition of hems

- Improved user guidance: Select material in STEP import

- Generation of unfolded dimensions or evaluation of bending lines

- In case of negative hems, the folding beam adjustment moves to exact position

- Improvements in the tool menu

- Optimized setup of the folding beam tools with limited number

- Selection menu: Bending radii more than twice the material thickness, can be made as "normal" bend or radius step bend

- Improved calculation for radius step bending

- Improved GEO file import for:

- interrupted bending lines

- Radii depending on sheet thickness

- Hems

- The beams where a tool change will be made within the program cycle will be shown graphically

- Manual changes of the bending sequence enabled

- The tool menu shows the max. sheet thickness of the tools

- Error corrections:

- In some situations machine stop with max. sheet thickness

- In certain cases wrong calculation of unfolded blank dimensions

- Tool configurations were not updated on power-up

- Preset dimensions of the blank are set correctly

- Improved length correction when using the front suction cups

- Preset blank dimensions adjusted to length and width when drawing a new part

- Error when opening the job list fixed

- New folding beam tools implemented

- New UpDownTools implemented

- Length correction considers the use of the front suction cups

- Allowed protrusion of flanges beyond the bending line is calculated in relation to the sheet thickness

- Selection of part base after a STEP file import is implemented

- Bending strategies with SnapTools are calculated as soon as SnapTools are selected in the tool menu

- Flange lengths in the correction menu are shown for each bend

- Length corrections for flanges increased from 10 to 20 mm

- Individual flanges can be deleted after file import

- Collision calculation considers increased free space for machine cladding

- Web server: Retrieval of bent jobs with time stamp possible (max. 1 hr)

- New upper beam tools implemented

- Collision indication fixed when using the front stop

- Improved strategy for setting up the folding beam tools together the UpDownTools

- Reduced speed of the suction table selectable

- Simultaneous movement of folding beam adjustment and suction table

- Part correction: selected flanges are color-coded

- Possibility to delete single flanges after STEP import

- Program start implemented in each bending line

- New upper beam tools implemented

- On machine configurations with a safety light beam at the folding beam side, bent parts can also be unloaded from the folding beam side

- Reduced folding beam speed can be selected for each bend

- New UpDownTools implemented

- Collisions between UpDownTools and pre-bent flanges avoided

- Material tables implemented for radius step bending

- When step bending a radius material expansion is compensated

- The hemming position is calculated based on the upper beam tool geometry

- New upper beam tools implemented

- New folding beam tools implemented

- Tool management changed for upper and folding beam tools

- New step bending interface for radii bending incl. correction tables

- New upper beam tools implemented

- New folding beam tools implemented

- New bending strategies (bending flanges longer than folding beam stroke)

- New folding beam, upper beam and lower beam tools

- Integration of the pneumatically actuated safety window (toolcover)

- Configuration level implemented

- New machine models implemented

- Unnecessary tool changes eliminated

- Installation routines for models and versions adjusted

- Web interface extended with “getmachinedata” function (Industry 4.0)