XLTbend Software 1-click programming

XLTbend Software

1-click programming

XLTbend Software

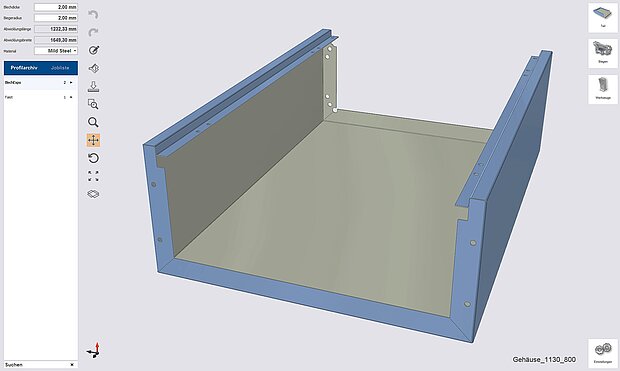

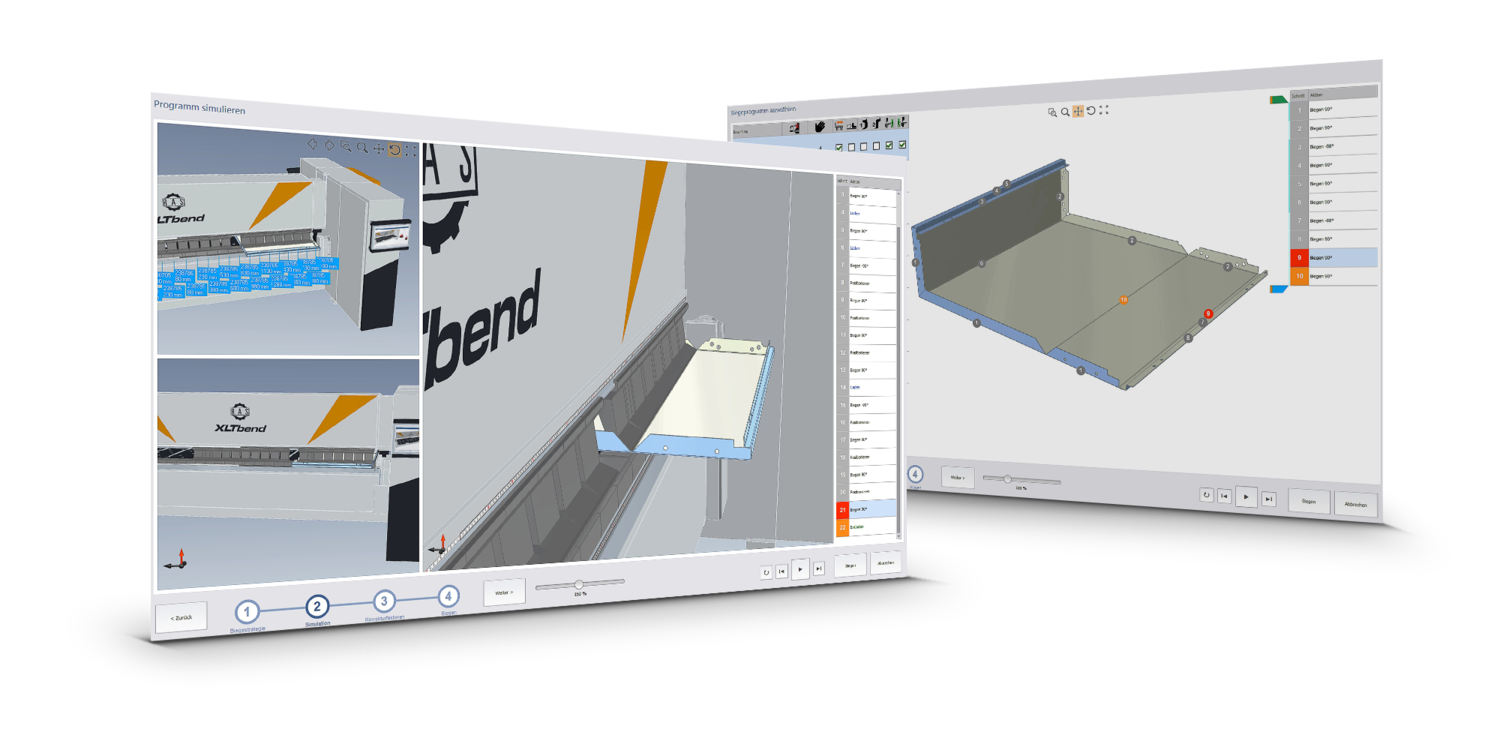

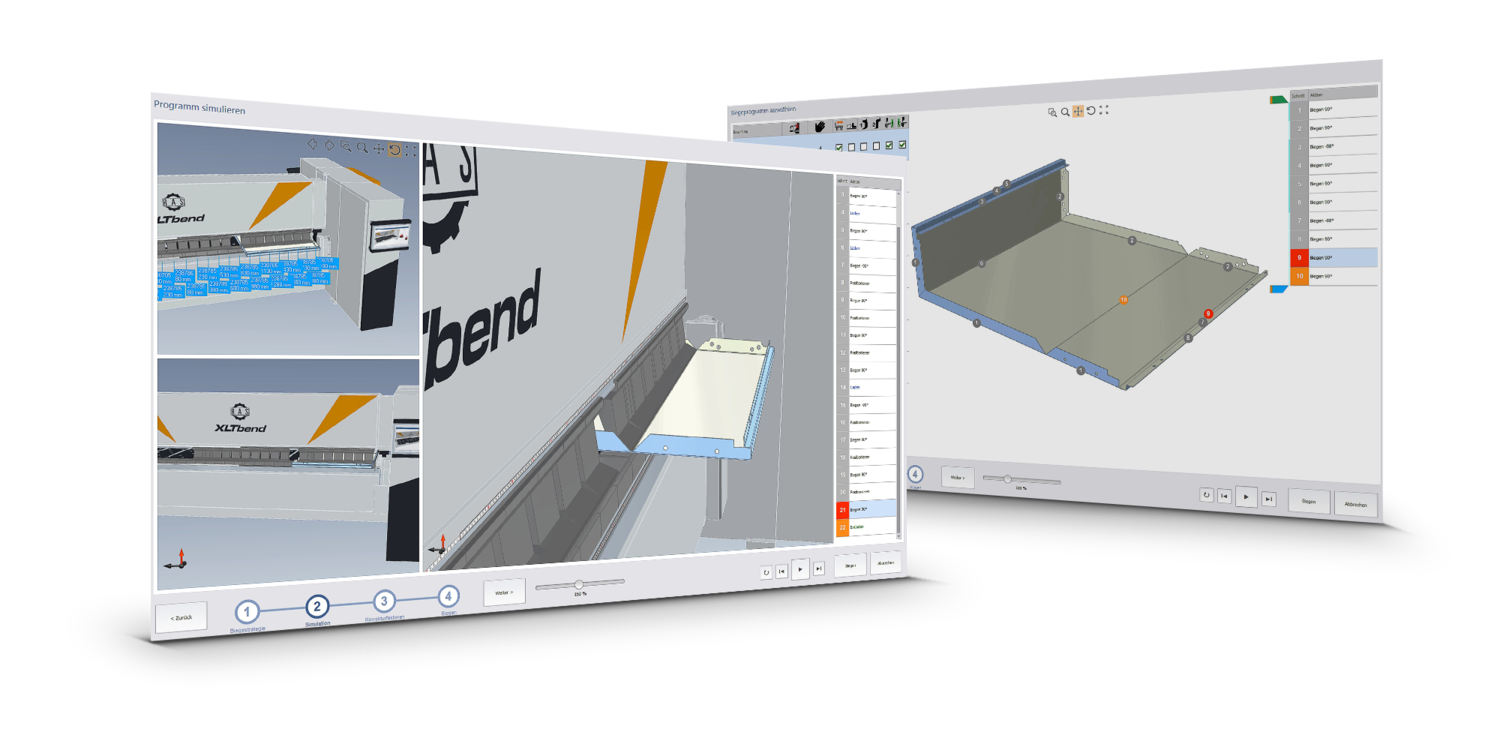

The XLTbend software has been created specifically for the XLTbend.

Import a part

- Create a part program automatically.

- Import a STEP, DXF or GEO file with the part geometry.

- The software analyzes the STEP file and automatically generates a 3D model. For DXF files, the programmer has to add to the bend angle.

- Overbend angles for springback compensation are added from material tables.

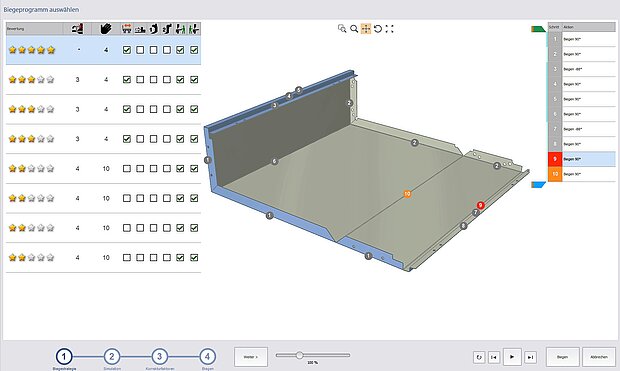

One click programming

- The software programs the bending sequence including handling operations automatically and with a single mouse click!

- If there are different folding sequences (fold short side before long side or vice versa), the software shows a ranking of the alternatives.

- The automatically created program sequence also includes the tool setup and the part loading position (with ViN - Virtual Navigator)

Software versions

Have you signed a software update agreement?

This allows you to update your Machine and Office Software to the next level.

- Includes free Machine software updates

- Includes free Office software updates

- Machine software and Office software versions must match

- For updates of additionally purchased Office licenses, the update packages for subsequent licenses are required

- Online connection to the PC must be available

What do I need to do?

Please contact RAS. After checking the data, we will contact you. We need the following information:

- Adress

- Contact person with Email and Phone

- Machine number

- Improvement: stop handling for “obtuse flanges”

- Manual resolution of the side bending position

- New upper beam tools

- Optimization of bending rule restoration

- Improvement: “Object reference not set to an instance of an object”

- Improvement: manipulator positioning

- Bugfix: Integrated stations

- Optimization: Improved performance of strategy calculation

- Bugfix: Avoid unnecessary operator side changes

- Bugfix: Apply selected loading variant

- Bugfix: Loading at right-angle stop

- Bugfix: Restoration of stored bending instruction

- Bugfix: Restoration of stored lateral loading position

- Bugfix: Rounding error in collision control

- CADImporter: Optimization of radius length compensation

- Parameterizable weighting of central bending

- Integrated stations support upper beam clearances

- Integrated stations support down tools

- Parameterized performance of strategy calculation

- Significant improvement in strategy calculation performance

- Avoiding permissible upper beam gaps (AvoidInnerUpperBeamToolGap)

- Bugfix: Loss of manual bending instruction when editing text infobox

- Bugfix: Error message “Index out of range”

- Bugfix: Bendex splash screen frozen during machine restart

- Bugfix: VBL – Object reference not set to an instance of an object

- Bugfix: Office machine – Profile archive display

- Bugfix: Upper beam clamping without vacuum gripper support

- Bugfix: Unnecessary & inconsistent upper beam station offset at program start

- Bugfix: Manual bending program – incorrect MaY values

- Bugfix: Display of measuring tape for upper and bending beams

- Bugfix: Single stopper and tilting loading variants

• Bugfix: Virtual bend lines

- New upper and lower beam tools

- Maintenance update

- New language files implemented

- New file manager

- Bending with Parameter (BWP)

- Optimization of SheetSupport

- Optimized vacuum gripper coverage

- Optimized collision handling when clamping with upper beam

- Optimized tool change position for upper beam

- Adjustment of default firewall rule

- Improved handling of stored bending specification / processing status

- Optimization positioning for hems (lateral and axial)

- Optimization of collision consideration

- Bugfix CAD export (IGES)

- Improved usability for tool position identification

- Bugfix flipping press May-Retract

- Parameterized performance of strategy calculation

- Parameterized weighting of central bending

- New upper beam Tools

- Corrected tool metadata for specific tool set

- Maintenance update

- Bugfix: import profile folders

- New language files implemented

- Beta feature: Bending with Parameter (BWP)

- Image file machine status information

- Reduction of the user instruction “Hide holes...”

- Reduction of tool changes

- Optimized bending part positioning during hem pressing

- Bugfix: VBL upper beam tool setup

- New language files implemented

- New upper beam tools implemented

- Bugfix: A table sheet was not displayed for a stop variant

- Bendex Office show machine archive

- Display for tools with plastic insert

- General optimizations of strategies with hems

- New tools and manipulator

- Various tool metadata corrected

- Upper beam tool change position can be parameterized

- Optimized folding beam support when unloading negative legs

- Optimization of bending part loading

- Optimization sheet metal—machine collision control

- Text info box implemented

- bending program entry supports separated hems

- Language files implemented

- Fixed error when restarting Bendex with corrupt bending part

- CADImporter “Missing flange” optimized

- “Pendulum parameter handling” error fixed

- Language files implemented

- New manipulator

- New upper beam tools implemented

- New bending beam tools implemented

- New handling concept (TVU)

- New tools and manipulators

- Fixed problem with advance tools / UbT_FbMaxAngle_BendArea3

- Language files implemented

- Processing inconsistencies revised

- Preview of already calculated strategies

- Abort behavior of strategy determination optimized

- User-friendliness of virtual bending lines optimized

- Collision analysis optimized

- Bending part alignment CAD import optimized

- New language files implemented

- New upper beam tools implemented

- New bending beam tools implemented

- Reactivation of parameter “Minimum radii step angle”

- Bug fix tool display

- New upper beam tools implemented

- New bending beam tools implemented

- New language files integrated

- Menu option for automatic alignment of boxes during CAD import implemented

- Offset input in the envelope dialog has been removed

- New upper beam tools implemented

- New bending beam tools implemented

- User interface adapted

- Feed tools with the bending strategies implemented

- During STEP import, the sheet thicknesses valid for the machine are queried and not imported if they are exceeded or not reached

- Length and width of the sheet metal processing in the job list exchanged

- dialog entry point moved and implemented in the job list

- Category imported in the profile archive has been integrated

- Slider for speed setting implemented in the simulation