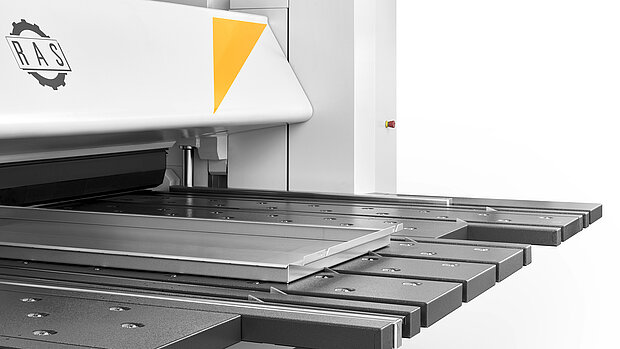

Maximum bending

flexibility for cassettes,

boxes and profiles

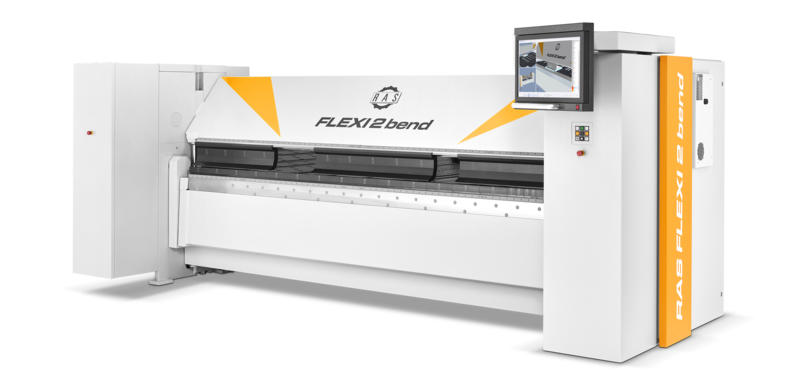

FLEXI2bend Bending centers

FLEXI2bend: Programming and Bending

Metal Folding Machine RAS FLEXI2bend

FLEXI2bend: Programming a stainless drai...

Metal Folding Machine RAS FLEXI2bend

FLEXI2bend Expanded Metal: Wide Stop Fin...

FLEXI2bend ALU 3mm - 4m Lenght

FLEXI2bend at Roofer Schnyder

Easy, fast, flexible

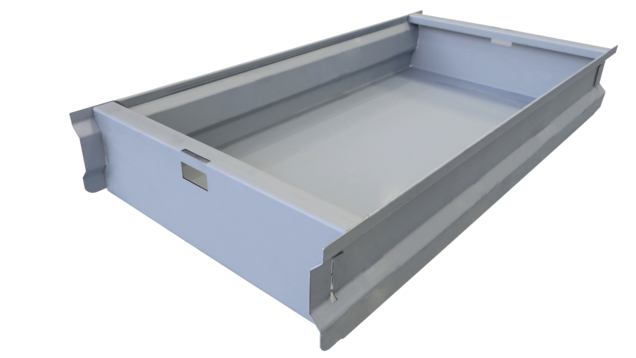

The FLEXI2bend metal folding system can be used to produce almost any metal bending part geometry. It is thus a materpiece of flexibility. Unique and complex parts with high added value are bent by the FLEXI2bend with the same precision and repeatability as simple cassettes, panels or profiles.The Bendex software automatically programs the parts, evaluates alternative bending strategies, and shows the bending sequence on the monitor in 3D. Expert knowledge converted into software!

- Large free space around the tools: allows flexible part design

- Segmented upper beam tools for box and panel bending

- Automatic recognition of a tool change

- Segmented folding beam tools for interrupted bend lines

- Automatic clamping of the upper beam and folding beam tools

- SnapTools: automatic retraction from side flanges

- Fast beam movements: high productivity and throughput

- Intelligent crowning system for perfectly straight bends

- Rectangular gauging system or center extended T gauging system

Upper beam

The upper beam opens and closes with inpressive speed. As the open and close position is programmable, you can create open or closed hems, thus making your parts unique and versatile. Radii can be created by individual bending steps and without special tools. The upper beam shape offers large free space in front and behind of the beam.

- Fast movements for closing/opening

- Hemming: closed, open, tear-drop hems

- Radius bending without special tools

- Large free space in front of the upper beam (part design flexibility)

- Rigid upper beam for straight bends

- Servo drives and absolute encoders

- Accurate positioning, no calibration

Folding beam

The deep and rigid folding beam of the FLEXI2bend metal folding machine stands for excellent bending results. The intelligent crowning system automatically compensates for deformation of the beam caused by the bending forces. The FLEXI2bend thus achieves straight bends with thin or thick sheets, all types of material, long or short flanges, and no matter of you bend in the center of the machine or on the side. Fast motion sequences ensure high productivity. The automatic adjustment to sheet thickness and bending radius increases productivity and flexibility for small batches.

- Fast movement: short cycle times

- SpeedOptimizer increases the speed by 20% by releasing the part while the folding beam moves down.

- Deep folding beam: excellent bending results

- Intelligent crowning system automatically compensates beam deformation

- Automatic adjustment for material thickness and bending radius

- No downtime for machine adjustments

- Automatic clamping of the segmented folding beam tools

- Gentle and scratch-free bending of coated materials

- Servo motors and absolute encoder: quick operation, no calibration

- Folding beam can be used as a stop for oblique-angled blanks.

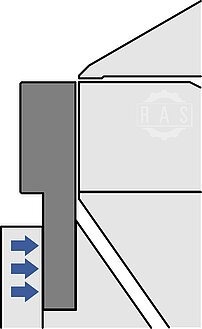

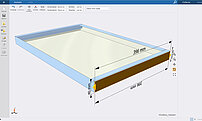

Gauging system

The fingers of the gauging system position the workpiece for each bend. All stop fingers disappear below the table surface when the part has to be rotated on the sheet support table.

- Fast positioning, repeatable accuracy

- Even for large parts no 2nd operator needed (50% cost saving)

- Sheet support carries the weight of the blank

- Solid front and rear stop fingers

- Servo drive and absolute encoder: no calibration

- Adaptive to working task and available floor space

- Center orientation for best bending results

- Rectangular backgauge 10-1550 mm

- T-gauging system for big parts (10-3050/4050 mm)

- Active popup squaring arm for narrow parts

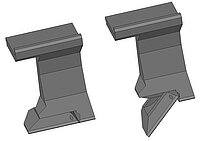

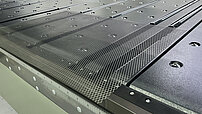

Versatile tooling system

The high tensile and precision ground upper beam tools are automatically clamped in the tool seat. No other tooling system offers so much free space for all kinds of bending geometries. Handy tool segments simplify tool setups for the operator.

- Large free spaces for part design flexibility

- Sharp tools for bending profiles

- Segmentierte Geißfußwerkzeuge für Boxen, Paneele und Kassetten

- Radius tools and special tool shapes on request

- Short set-up times due to handy tools and automatic tool clamping

- Exactly fitting individually manufactured segments (can be retrofitted at any time)

- Automatic recognition of a tool change

- Automatic recognition of the tool height (safety function)

- Folding beam tools for different thicknesses and Z bends

- Finger pockets in lower beam tools for smallest stop dimensions

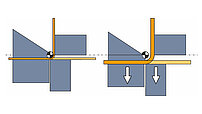

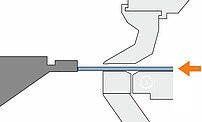

SnapTool corner tools

The SnapTool corner tools with a hinged foot automatically retract from parts with side flanges. The hinged foot moves down when the upper beam opens and snaps back into the working position as soon as the tool has moved out of the bent part.

- A manual rotation of the bent parts at the end of the bending cycle is not necessary

- Side free space in the hinged area of the SnapTool is 30 mm

- Designed for the same sheet thickness as the other tools of the tool set

- Software calculates the SnapTool positions

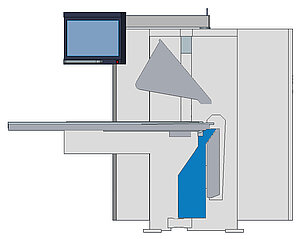

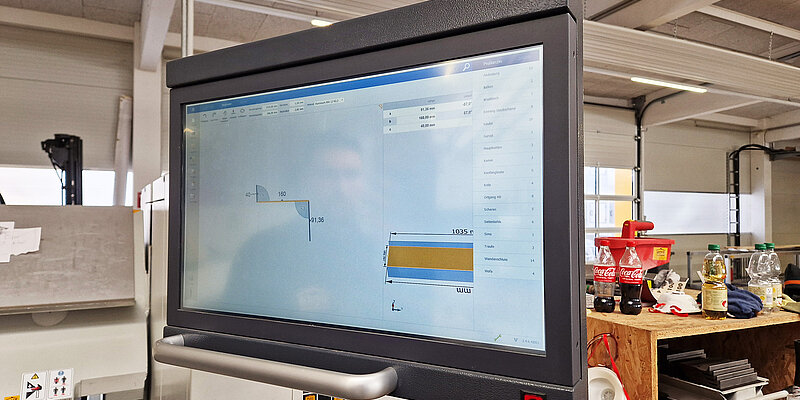

Automatic programming of the bending sequences

Where programming used to require a lot of expert knowledge, today there is a high degree of intelligence in the Bendex software. Parts can be entered on the clearly visible screen or imported as STEP, DXF or GEO files. With a single mouse click, the software automatically programs the entire bending sequence, including tool setup.

- Clear display on 24" touch monitor

- Simple creation of profiles and panels

- Exact and error-free transfer of CAD data

- Automatic programming of bending sequences

- Software suggestion of the best folding sequence

- 3D simulation of the bending process

- Graphic operator guidance during the bending sequence

- Highest bending accuracy due to material tables

- Program import from the office software

- Loading individual programs or processing job lists

- Monitor can be rotated on the swivel arm

- Operation from the folding beam side

- Operation from the gauging side

- Online support via TeamViewer

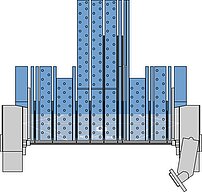

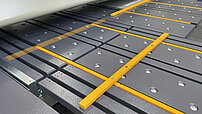

Bending expanded metal

Version 1

Due to the mesh size of expanded metal, the standard stop fingers of the FLEXI2bend metal folding machine can sometimes position the blanks on the nodes and sometimes between the meshes. As a result, reliable flange dimensions cannot be achieved. In a special version of the gauging system, the front fingers are widened to 25 mm. To enable bending of small flange dimensions, the finger pockets in the lower beam tool are also widened.

Bending expanded metal

Version 2

In the second version for bending expanded metal, the gauging system is equipped with manually relocatable stop bars. This allows a wide range of stop dimensions to be approached. For the smallest dimension, the stop bars move to the rear of the upper beam tool. The maximum dimension depends on the gauging system configuration (rectangular gauging system or J-shape).

|

RAS 73.30-2 |

RAS 73.40-2 |

|---|---|---|

| Working length | 3200 mm / 126" | 4060 mm / 159" |

| Material thickness max (400 N/mm²) | 3.0 mm / 11 ga | 2.5 mm / 13 ga |

| Upper beam upstroke max | 300 mm / 11.8" | 300 mm / 11.8" |

| Gauging system (rectangular) | 10–1550 mm / 0.39"–61" | 10–1550 mm / 0.39"–61" |

| Gauging system (T-shape) | 10–3050 mm / 0.39"–120" | 10–4050 mm / 0.39"–159" |

| Auto material thickness adjustment | yes | yes |

| Auto bending radius adjustment | yes | yes |

| Auto tool height recognition | yes | yes |

| Bendex-Programming | automatic | automatic |

| Machine dimensions (rectangular) | 4560 x 2380 mm / 180" x 94" | 4560 x 2380 mm / 213" x 94" |

| Machine dimensions (T gauging system) | 4560 x 3870 mm / 180" x 152" | 4560 x 3870 mm / 213" x 192" |

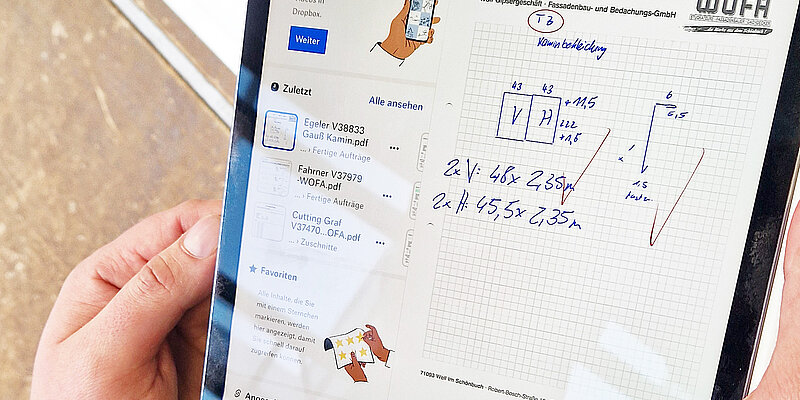

WOFA-Wolf GmbH's building plumbing division has taken a significant step towards efficiency and digitalization. Thanks to the integration of the RAS FLEXI2bend folding machine, the digital Bendex machine control system and the Bendex merchandise management system, the company has fundamentally modernized its work processes.