Fully automatic bending of

even complex parts up to

3 mm sheet steel

MiniBendCenter 2 Bending centers

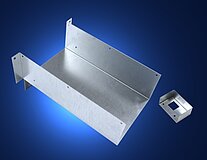

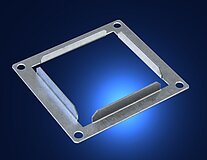

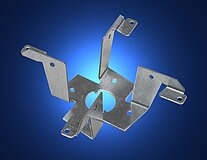

MiniBendCenter: Demo part

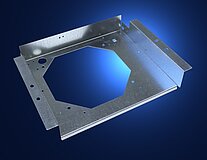

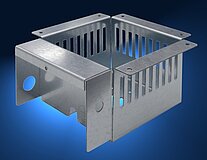

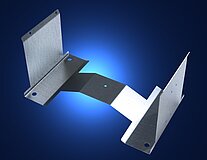

MiniBendCenter: Fan components

RAS MiniBendCenter: 3D programming

MiniBendCenter: Electronic industry comp...

MiniBendCenter: Laser blank loading syst...

RAS MiniBendCenter at company Ruck

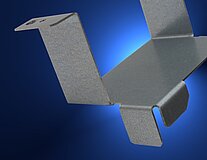

MiniBendCenter: Blanks with studs

MiniBendCenter: Bending of transformer c...

RAS MiniBendCenter

RAS MiniBendCenter: Finished parts runou...

MiniBendCenter bends copper parts

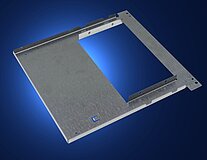

MiniBendCenter: Case components

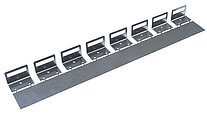

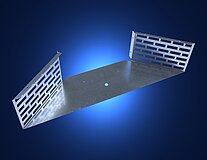

MiniBendCenter: Server rack components

RAS MiniBendCenter with intelligent load...

RAS MiniBendCenter with pallet system

MiniBendCenter: Finished parts into bulk...

RAS MiniBendCenter: Automated folding ce...

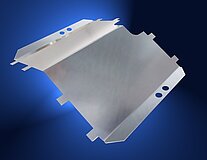

MiniBendCenter: Stainless steel profile

MiniBendCenter: Step bending of a funnel...

MiniBendCenter: Tapered Step bending

MiniBendCenter2

Revolutionary manufacturing technology

The world's first fully automatic folding center for precise and efficient sheet metal processing

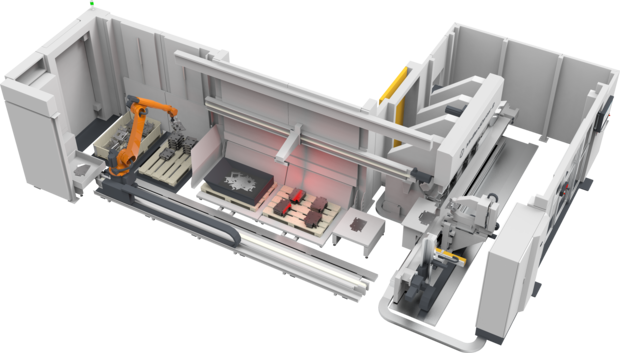

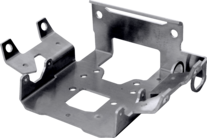

The RAS MiniBendCenter of the second generation is an innovative panel bending center that sets new standards in automated sheet metal processing. As the world’s first fully automated folding center for small parts, it enables seamless automation across the entire production chain: from automatic tool setup and blank loading, to precise alignment and measurement. A smart manipulator positions the sheet metal with high accuracy for the bending process, which can be performed both upwards and downwards.

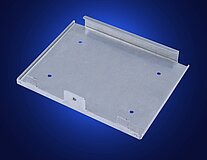

Fully automated bending is possible from sheet sizes as small as 50×40 mm, making the system ideal for manufacturers who demand maximum precision in small-part sheet metal fabrication.

- Only swivel bending center for small parts starting at 50x40 mm

- Automatic easy loading by robot (from bulk material or from stack)

- Automatic unloading by robot (stack on pallet or bulk material on pallet with frame)

- Automatic tool set-up

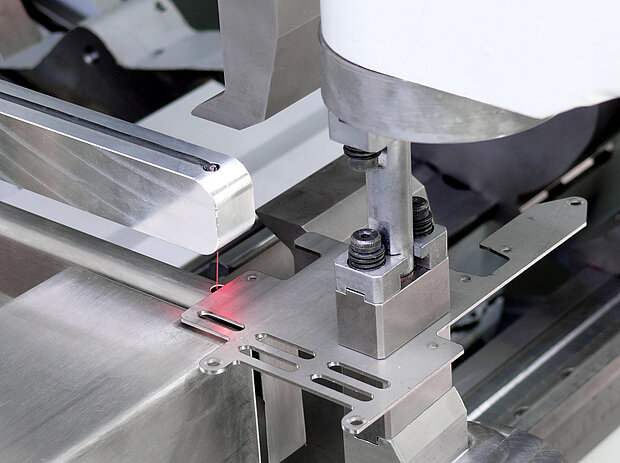

- Scanning of the supplied blanks

- Servo-electric manipulation for bent part positioning

- Automatic bending sequences with up and down bending

- Maximum precision and repeat accuracy

- Unmanned operation during the night shift

Efficiency and precision thanks to high-precision servo-electrics and intelligent robotics

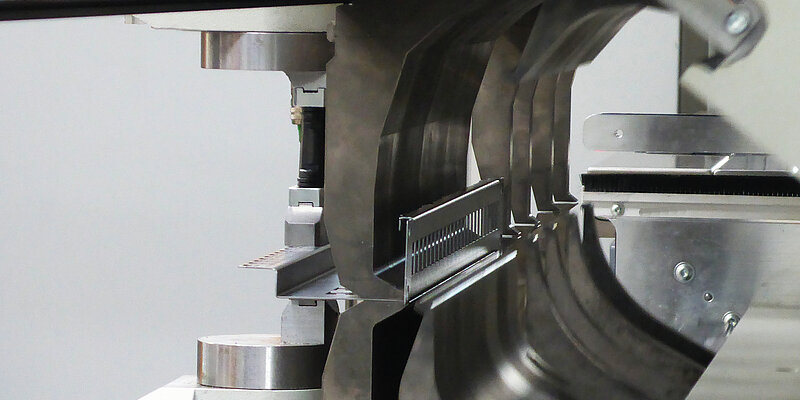

With the introduction of high-precision servo-electrics, the MiniBendCenter 2 sets new standards in terms of efficiency and precision. The integration of an intelligent robot revolutionizes the loading of punched or laser-cut blanks as well as the unloading of the finished bent parts, which it deposits or stacks unsorted as required. The newly implemented pallet changing station optimizes the material flow by providing a central point for feeding in new blanks and removing the processed parts. With these innovations, the MiniBendCenter 2 not only guarantees low unit costs, but also a quantum leap in productivity in automated sheet metal processing.

Blank loading

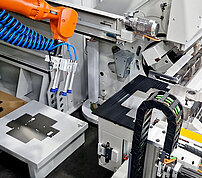

Intelligent robotic blank loading

A camera system enables the intelligent loading robot to recognize the position of the blanks of a bulk material quantity on a pallet. The software calculates which blanks form the top layer and which parts the robot can access. The robot then picks up one of the available blanks and feeds it to the MiniBendCenter 2.

Of course, the robot can also grip the blanks in stacks. The blanks do not have to lie exactly on top of each other. And the best thing is that the robot does not need to be taught or programmed. Simply start a bending program and the machine does the rest.

- No programming or teaching necessary

- Robot grips the blank and feeds it to the bending center

- Parts that are upside down are sorted out

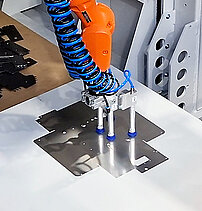

Multifunctional vacuum gripper

The multifunctional vacuum gripper allows different blank geometries to be fed without changing suction cups. Each individual suction cup is programmable and can be controlled separately. Two suction cups are fixed and the position of two suction cups can be adjusted.

- Additional flexibility gain for very different blanks

- Ideal for unmanned production

- The arrangement of the suction cups enables a variety of unloading options

Bending sequence

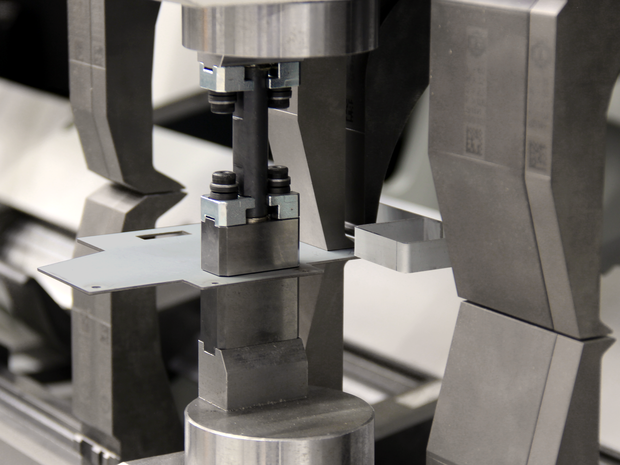

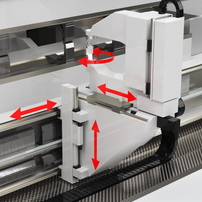

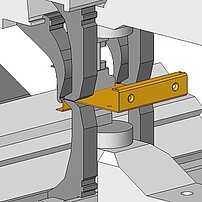

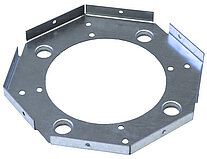

Automatic tool setup

The fast and automatic tool changer places the clamping and bending tools into position. Tools not used for a job are stored in the tool magazine. Due to its rotation axis in the gripper, the tool changer can place a tool in the upper or lower clamping beam as well as in the upper and lower folding beam.

- Automatic tool change in the shortest possible time

- Precise took positioning

- Unmanned shifts due to automatic tool setups

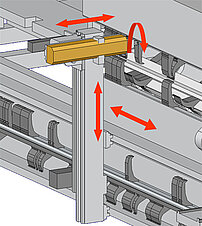

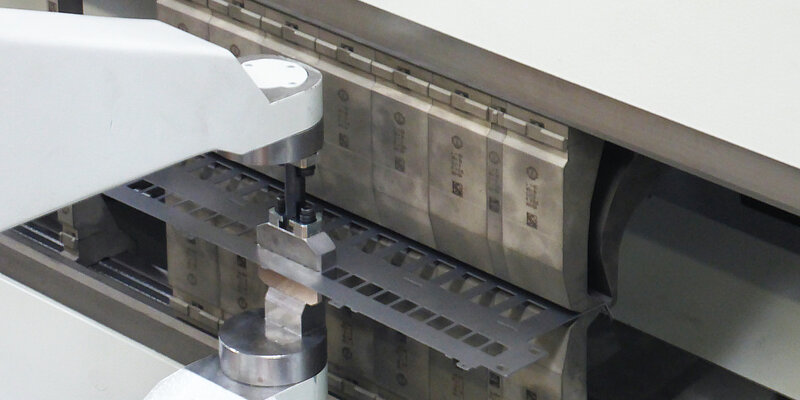

Manipulator

In the new generation of the MinibendCenter 2, the manipulator clamps, rotates and positions the bent part using high-precision servo-electric drives. As it can even move between the tools, its design opens up an extremely wide range of applications.

- Precise positioning and turning

- Highest bending precision

- Constant repeat accuracy

- Very small parts can be bent

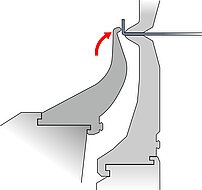

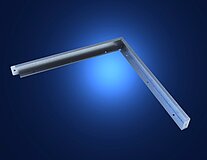

Bending up and down

The folding beams of the MiniBendCenter 2 can bend the sheet metal flanges up and down. The part does not need to be flipped when the bending direction changes. The workpiece always remains horizontal. There is no need to lift the part as with press brake bending.

- Simple bending sequences and therefore simple programming

- Fast bending cycles

- Low unit costs

Unloading and stacking bent parts

Intelligent robotic unloading

The intelligent robot not only loads the blanks, but also unloads the bent parts. The robot knows the position of the provided pallets and unloads the finished parts there. The robot can set up several stacks next to each other.

If the bent parts are not sensitive, the robot can also place them unsorted in a bulk container.

- No programming or teaching required

- The robot can unload finished parts stacked or unsorted

|

RAS 79.05-2 |

|---|---|

| Working length (for multiple tool stations) | 2500 mm / 98.5" |

| Blank dimension min | 50 x 40 mm / 1.97" x 1.57" mm |

| Blank dimension max | 600 x 600 mm / 23.6" x 23.6" mm |

| Material thickness max (400 N/mm² / 58,000 PSI) | 3.0 mm / 11 ga |

| Programming | 3D programming system |

| Machine dimensions (Robotic loading) | 9500 x 6100 mm / 360" x 260" |

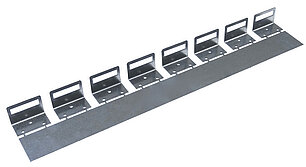

Company Triton from Pardubice in the Czech Republic is a manufacturer of data cabinets, power distribution systems and wardrobe lockers. Customers can design their own cabinets using the Triton product configurator. As a result production and machine flexibility need to be extremely high. The RAS MiniBendCenter bends small parts up to 600 x 600 mm in small to medium batch sizes. A optical scanner automatically finds the blanks on the pallet. Fed with this data, a robot loads the small-part into the bending center. After the automatic bending process is completed, the finished parts can be automatically delivered to different boxes. After one job is completed the tool changer automatically prepares the machine for the next job.