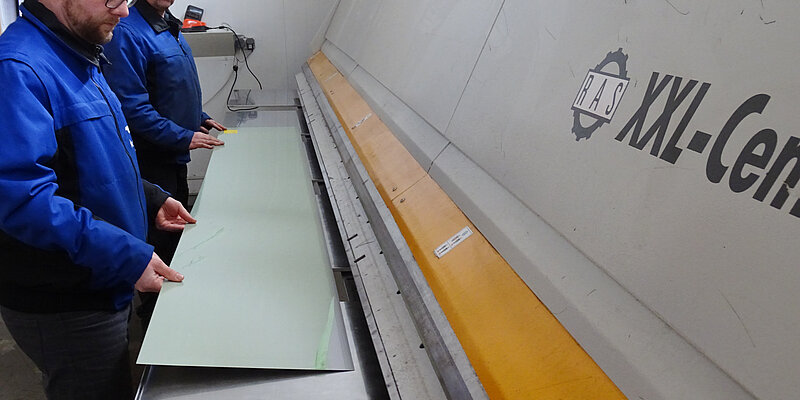

Simple insertion of the

sheet metal strips on the

out insertion tables

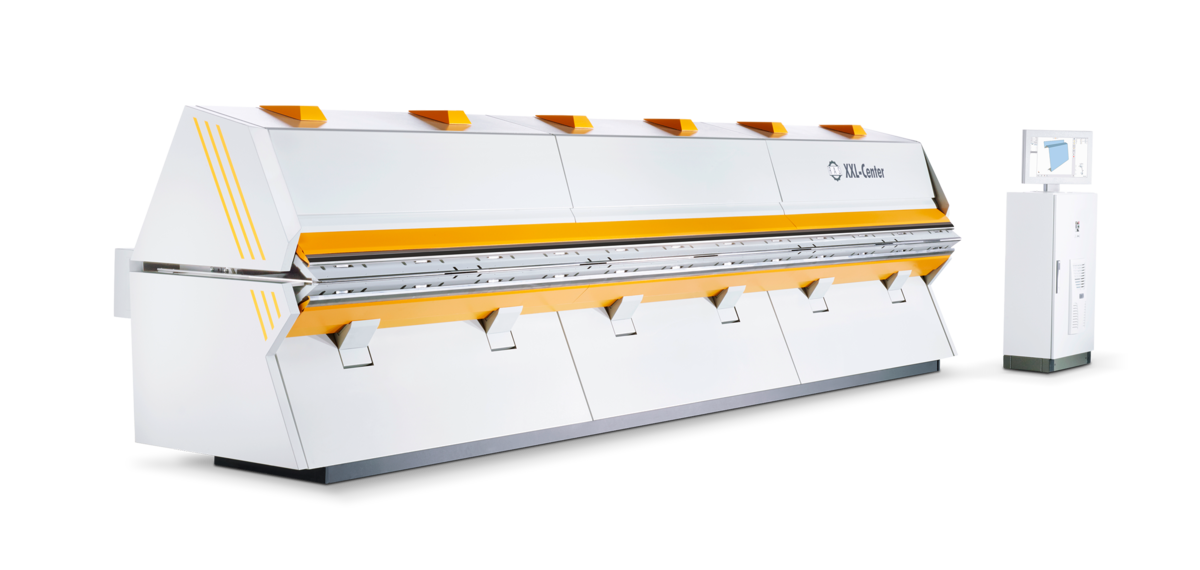

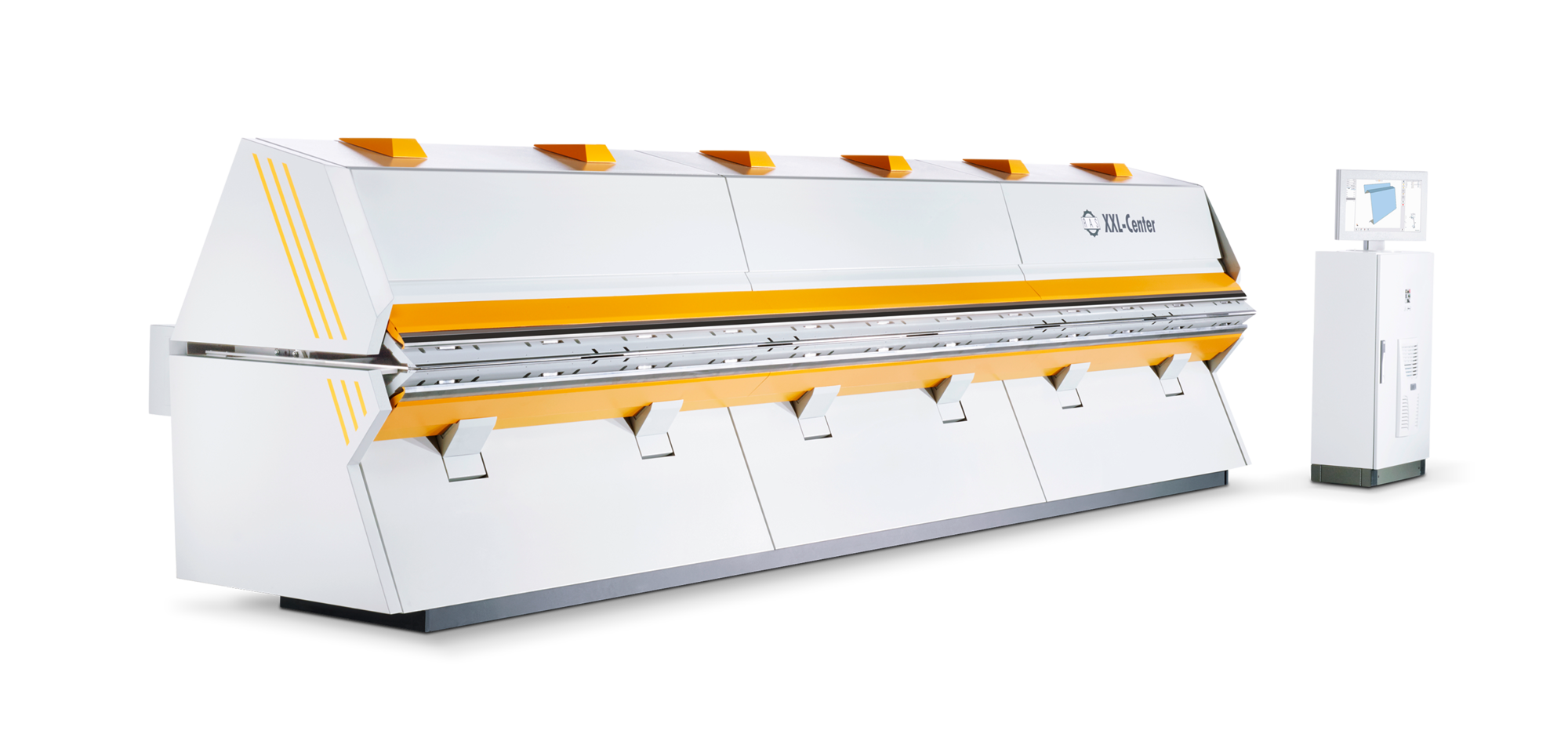

XXL-Center Bending centers

RAS XXL Center: 2nd generation long fold...

XXL-Center with slitter: Schütze GmbH

XXL-Center with CutModule

XXL-Center: Complex wall profile

Long folding XXL-Center (8 meter)

RAS XXL-Center: Corrugated parts

XXL-Center: Skylight dome

XXL-Center: corrugated panel

Bending Center RAS XL-Center

Bending Center RAS XL-Center

RAS XL-Center: Tapered parts

Bendex-Mobile and RAS XL-Center

XL-Center: Bending on hems

RAS XL-Center: Toolbox parts

XL-Center: Accuracy on 1.5 mm mild steel

Simple XL-Center programming

XL-Center: Star-shaped facade profile

RAS XL-Center bends roller shutter box

XL Center: Bending building profiles

XL-Center: Large free space

XL-Center: Coping

XL-Center: Part with manual operation

XL-Center: tapered parts

XL Center: Wall coping

XL-Center: Bending a roof ridge

Company Binder: Profile diversity

RAS XL-Center: Complex bending profile

XL-Center at roofer Schwaer

RAS XL Center buckle plate

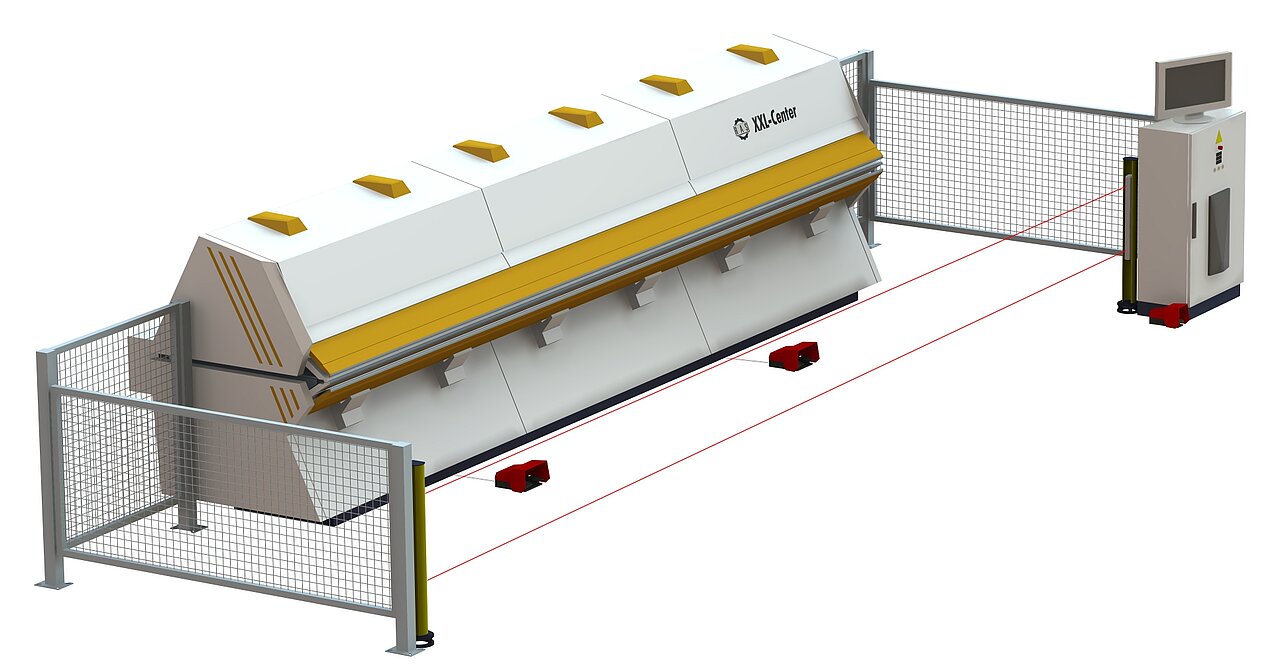

Efficient automation

Automated bending of long profiles

The XXL long folding center automatically inserts, squares, positions to the bend line, and folds the flanges up or down. No more rotation. No more complicated handling. No more second or third operator. The XXL-Center automatically produces precision long parts in record time.

- Machine for roof & wall profiles

- Automatic inserting and positioning of blanks

- Bending up and down

- Scratch-free bending of sensitive materials

- Large free spaces for maximum part design flexibility

- Automatic bending sequences

- Automatic 1-click part programming

- High productivity

Bending sequence

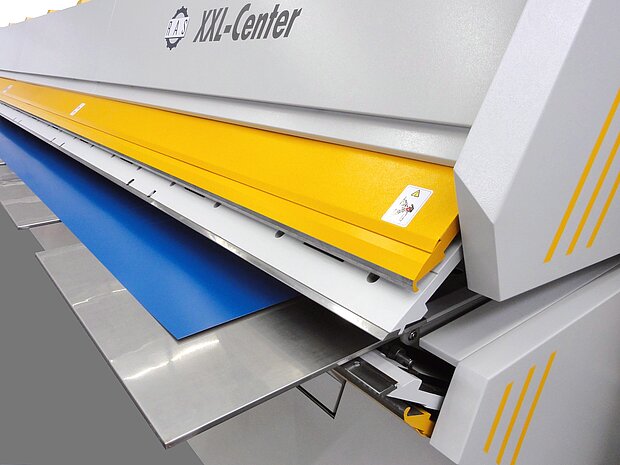

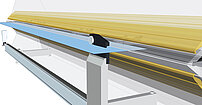

Blank loading with unique comfort

It has never been that easy loading a blank into a long folder. The stainless steel loading table automatically move out of the machine just as far that the operator can easily load the cut part.

- Easy material loading

- Fatigue-free and fast operation

- One operator for medium size blanks

- High productivity

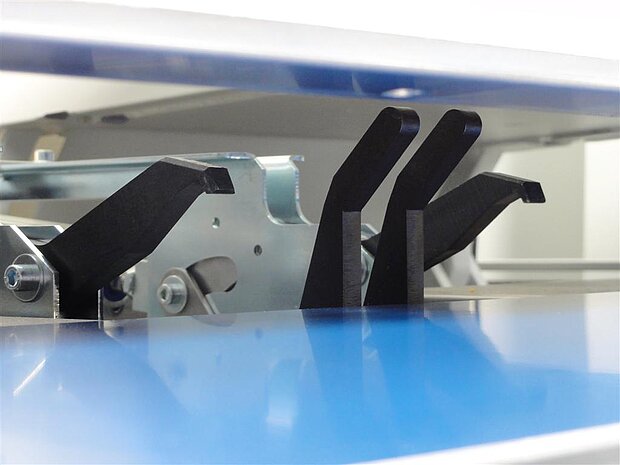

Accurate positioning

After the blank is squared the XXL-Centers grippers take over the workpiece. They hold and automatically position the part for each bend. The grippers can clamp on straight material, but can also clamp on a closed hem. Additional higher grippers can clamp over a pre-bent flange.

- Normal gripper are sufficient for almost all jobs

- High grippers can clamp over 25 mm flanges

- They come in addition to normal grippers

- Software automatically selects the grippers

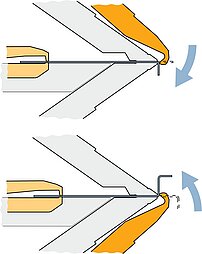

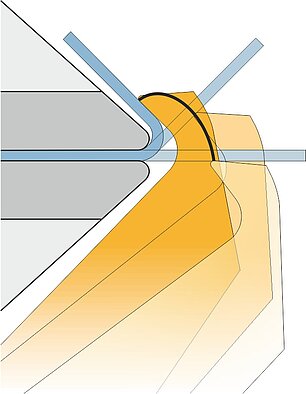

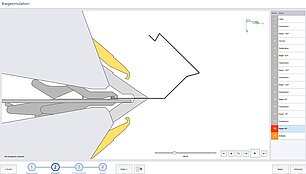

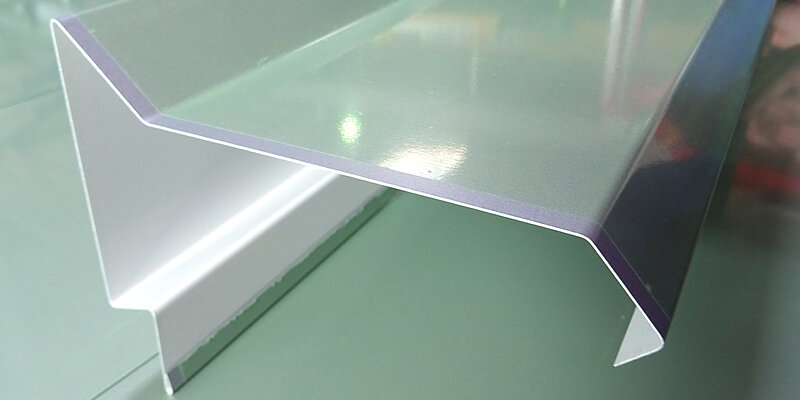

Bending up and down

Up and down folding eliminates a need to rotate the parts. Short cycle times, precision flange dimensions and angles, high levels of productivity and low costs per part guarantee a quick payback of the investment.

- No part flipping required

- Little swivel movement of folding beams

- Fast bending sequences

- High productivity, short payback period

CutModule for XXL-Center

If the CutModul is selected, the software shows where the operator has to insert the material strip. The XXL-Center pulls the metal workpiece into the machine, squares and positions ito dimension. The upper beam clamps the material and the cutting unit starts from its right home position and cuts the workpiece to the requested dimension.

- Cuts blanks to the exact width

- CutModule can be used up to 1.5 mm mild steel material

- Cutting gap and overlapping of cutting wheels adjustable

- Available for 4 and 6 meter models

- Can be retrofitted on second-generation XXL-Centers

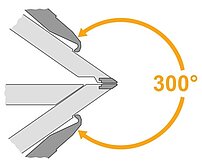

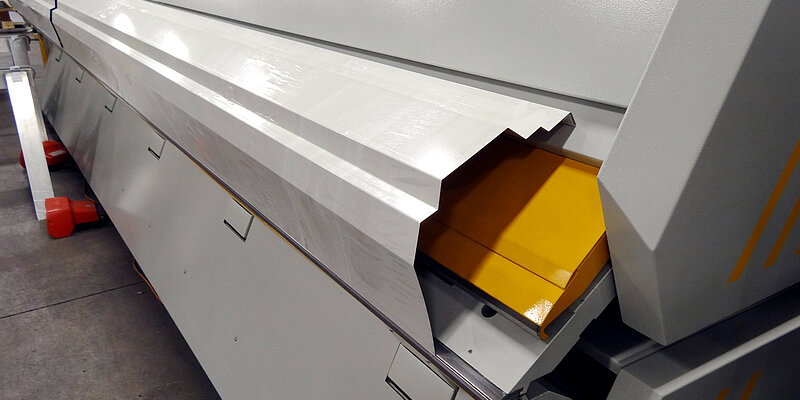

Bending complex parts

RAS has designed XXL-Center with maximum free space in front of the folding beams and has also patented this aspect. The extremely large free area of 300 degrees creates room for the most complex part geometries.

- Umlimited part design flexibility

- Folding beam already inside the part for the next bend

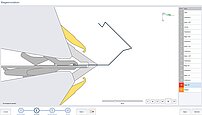

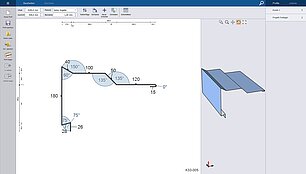

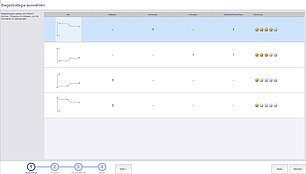

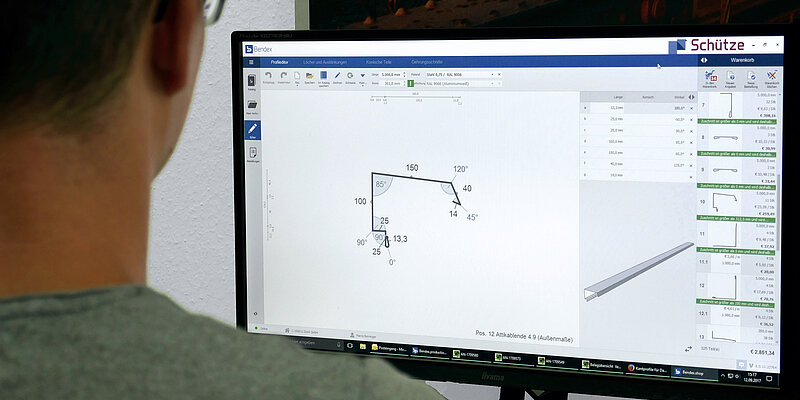

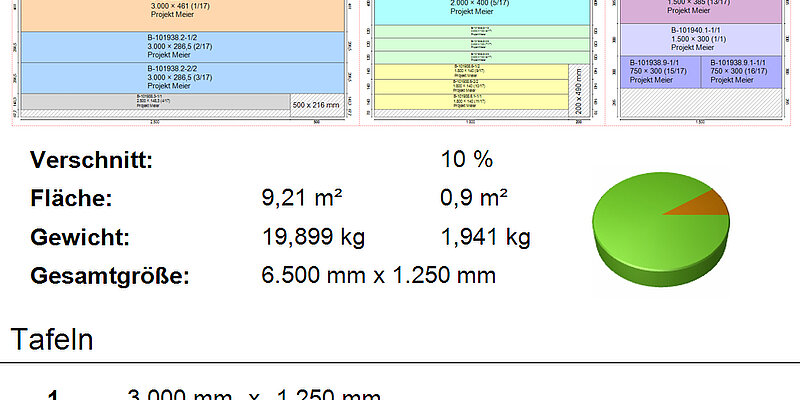

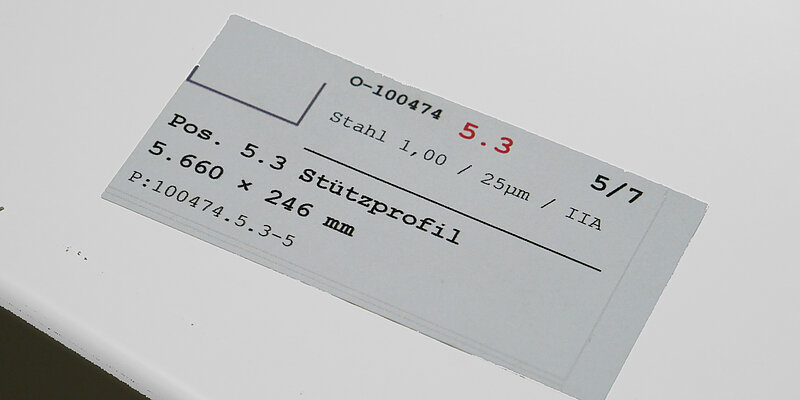

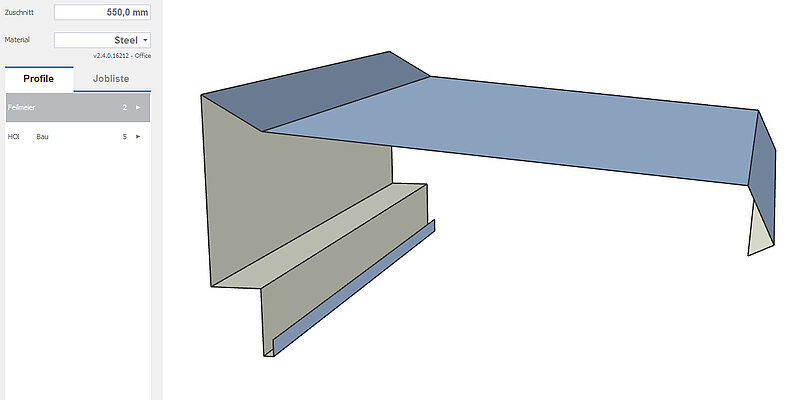

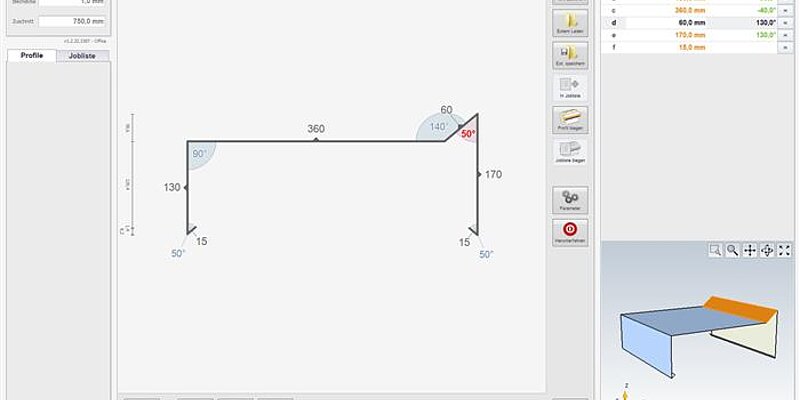

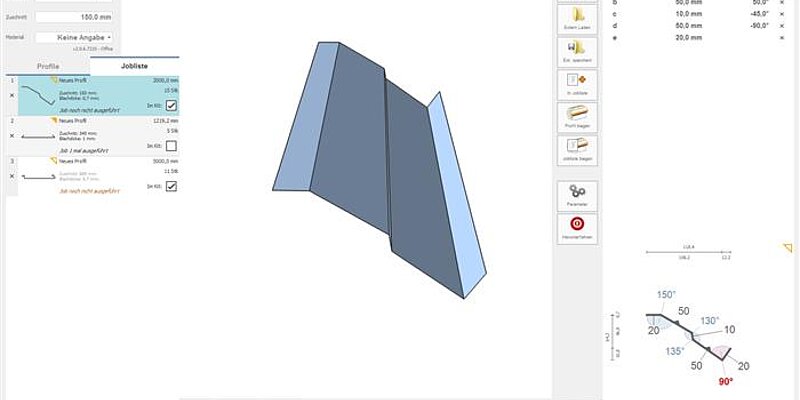

Automatic part programming

The operator draws the profile of the touch monitor or in the office using the Office software. The Bendex software automatically programs the part and suggests the optimum bending strategy. The software simulates the entire program cycle in either a 2D or 3D view.

- Dimensions and angles clearly visible even on complex profiles

- Automatic programming of the bending sequence with a single mouse-click

- No bending expertise required

- Software suggests the best bending strategy with a 5-star ranking

- 2D or 3D bending sequence simulation

- Visualizing possible collisions

- With Office-Software: Programming and feasibility study in the office

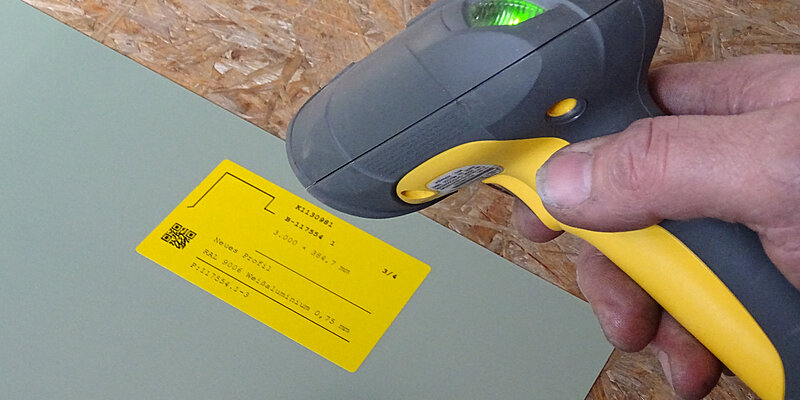

Program features

The unique and powerful Bendex software automatically programs the parts. Its enormous fetaure list increases the throughput and productivity of the machine many times over.

- Material and thickness selection (Auto angle correction)

- Hems: close, open, drop-shape

- Radius bending

- Unfolded blank calculation (inside dimensions)

- Profile archieve, Joblists, Similar part search feature

- Order processing with Bendex software (Professional / Ultimate)

- Online-Support via TeamViewer

- Online Software Updates

|

RAS 75.04-2 |

RAS 75.06-2 |

|---|---|---|

| Working length max. | 4240 mm / 165" | 6400 mm / 252" |

| Material thickness max (400 N/mm² / 58,000 PSI) | 1.5 mm / 16 ga | 1.5 mm / 16 ga |

| Material thickness max (700 N/mm² / 101,500 PSI) | 1.0 mm / 20 ga | 1.0 mm / 20 ga |

| Material thickness max (200 N/mm² / 29,000 PSI) | 2.0 mm / 24 ga | 2.0 mm / 24 ga |

| Free space in front of the beams up to | 300° | 300° |

| Blank loading tables | yes | yes |

| Automatic blank squaring | yes | yes |

| Grippers | yes | yes |

| Programming | automatic | automatic |

| Cut-Module | optional | optional |

| Machine dimensions | 6400 x 3500 mm / 252" x 138" | 8600 x 3500 mm / 339" x 138" |

On their homepage, Schuetze GmbH reports that they have invested in a slitting line and a state-of-the-art XXL-Center long double folding machine. This allows them to produce and deliver profiles for roofs and walls quicker and more economically. The secret of success is, however, the organization in the background using the Bendex.professional software. Only the combination of machine and software led to this achieved efficiency.

In 2014, Feilmeier AG wanted to acquire an additional long bending center with bidirectional bending; they wanted a machine that can bend the metal both up and down without any flipping of the part required. Key to their decision to purchase a RAS XXL-Center was the fully integrated Bendex-Software, which automatically programs the parts. The firm’s owner Ludwig Feilmeier had a clear vision of what he expected from his new machine. The large space in front of the folding beam allows Feilmeier to bend parts that they could not offer before.

Jim Huff, owner of H&H Architectural Metals from Denver proudly says: "In the past we needed 20 minutes with 2 people to bend a complicated gutter. With the RAS XXL-Center we run 2 gutters at a time in 2 1/2 minutes with a single person." Machine operator Kevin pulls two metal blanks from the side onto the machine's sheet support tables. The XXL-Center automatically squares the blanks and runs the parts completely automated. Jim Huff says with a smile: "35 years ago, my wife Kathy and I founded H&H Architectural Metals with $ 6 and 38 cents starting capital." Today the company operates in their own 5500 sqm building with the latest machinery equipment. The succession is also secured by son Chad Huff.

The well-known SCHRAG Group is specialized in the production and distribution of roof and wall profiles for industrial buildings. In order to achieve their goals of reliability, speed and quality, the SCHRAG Group uses several XXL-Center long folding center from RAS which automatically programs the profiles. Technical director Bernd Wurmbach has noted: "If we run a 0.75 mm part 5 meters long with six to seven bends, the XXL-Center is about 50% faster than our other bending machines."

In November 2002 FN Profilblech Center GmbH from Bad Rappenau, Germany, installed a RAS XXL-Center. Today the specialist for folded roof and wall parts cannot imagine how they were able to run their business without the high-performing long folding center. What took three shifts on a press and a traditional long folder before, is now completed in one and a half shifts on the XXL-Center.

Since March 2002 Rudolf Wiegmann Umformtechnik from Bersenbrueck in Germany have produced folded profiles for roof and wall with an XXL-Center from RAS Reinhardt Maschinenbau GmbH. The sheet metal specialist processes 2500 tons of coil material and 200 tons of blanks per year. A well equipped steel and aluminum warehouse, fast and precise production, as well as their own assembly company made the Wiegmann Group a respected and reliable partner in the industrial building industry.