Rollforming of all common

seams on air ducts and pipes

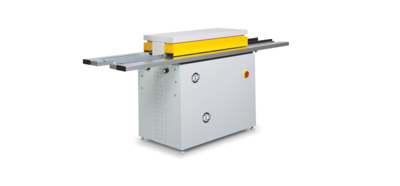

SpeedySeamer Lockforming machines

SpeedySeamer: Seams for the ventilation ...

SpeedySeamer: Stainless steel air ducts ...

Lockforming machine RAS SpeedySeamer

- Economical, fast and profitable production in a single run

- Two sets of roll can be set up at a time

- Matching seams can be produced without any downtime

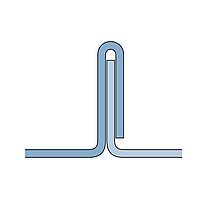

- Combinations: Pittsburgh/Standing seam and Snap-lock/Cam-standing seam

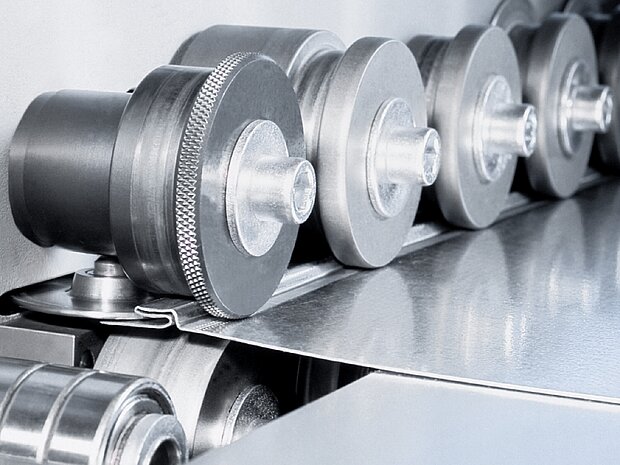

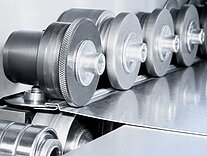

- Durable rolls made of case hardened special steel

- Table height adjustable to the sets of rolls

- Wide gear box improves guidance and increases the seaming quality

- Hardened run-in guides (reduced wear)

- Run-in guides with pins (processing beaded sheets)

- Adjustable roll for straightening or pre-rounding of seamed sheets

Quality profiles and high throughput

Two sets of rolls being setup at a time allow the production of corresponding seams without ans downtime. Examples of matching seams: Pittsburgh/Standing seam or Snap-lock/Cam-standing seam. With its 16 m/min speed, the SpeedySeamer produces several hundred meters of air ducts every day.

- Roller shafts, housed in roller bearings provide high-quality profiles

- The wide gearbox improves the seaming quality

- A lifting device avoids cracking of aluminum sheets

Flexible and profitable operation

The table height can be adjusted individually for each set of rolls and makes the machine ready for current and future applications. The hardened run-in guide rails reduce the wear caused by plasma-cut sheets. Pins in the run-in guide rails hold beaded sheets in position. With the adjustable roll at the run-out, seamed sheets can be straightening or pre-rounded. If you want to further increase the application diversity of the SpeedySeamers, use the guiding system for small blanks.

Stainless steel air ducts

The RAS SpeedySeamer can not only be used to produce air ducts made of galvanized sheet steel, but also for stainless steel air ducts that meet special requirements. These can be air systems for smokehouses, laboratory equipment, systems with aggressive media or systems with special cleaning requirements. With the Snap Lock Connection, a combination of Snap Lock Seam and Cam Standing Seam, air ducts up to 3000 mm long can be produced.