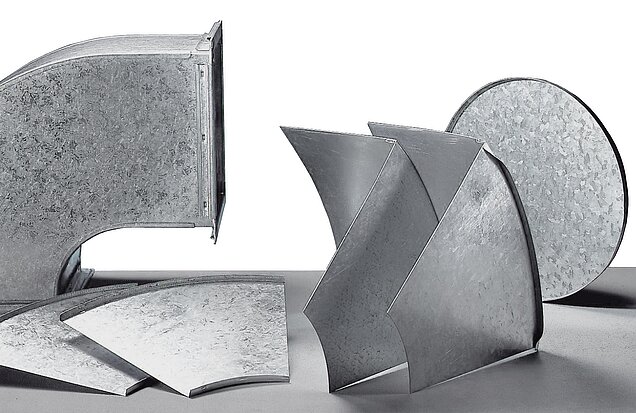

Quick turn-up of flanges

on straight, round and

curved duct segments

RAS 21.20 Flanging machine

Flanging arc segments

The RAS 21.20 flanging machine offer a proven technology in the ventilation industry, when arc segments are manufactured for air ducts. The forming rolls turns up 90 degree flanges on radius cheeks so that the parts are ready for Pittsburgh or Snaplock joints. Quick, Safe, Cost efficient.

- Standing seam for joints with Pittsburgh seam

- Cam standing seam for joints with snap-lock seam

- Attachment for cam standing seam cuts and pierces the cams

- Pre-bending station with adjustable stop

- Infinite adjustment for sheet thickness from 0.5 to 1.5 mm

- Spring steel insert in the machine table increases longevity

- Automatic sheet guiding system for flange heights (8 or 10 mm)

- Infinite speed for high productivity and safe material handling

- Configuration for stainless steel air ducts available

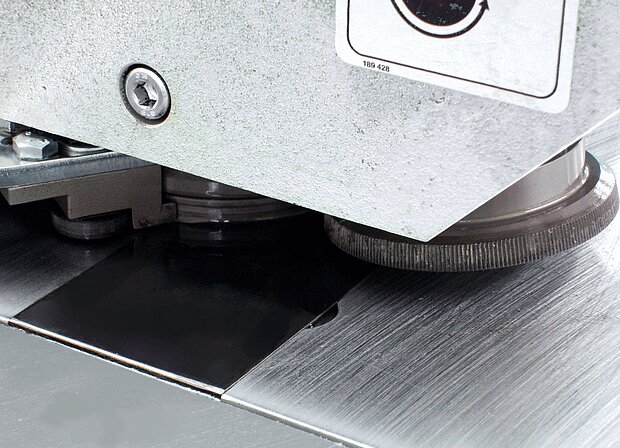

Durable machine table

The wide support surface at the run-in and run-out side of the machine supports the air duct components. A wear-resistant pressure piece at the forming point ensures the long lifetime of the forming station. An additional spring steel insert in the table plate reduces wear caused by plasma-cut metal sheets.

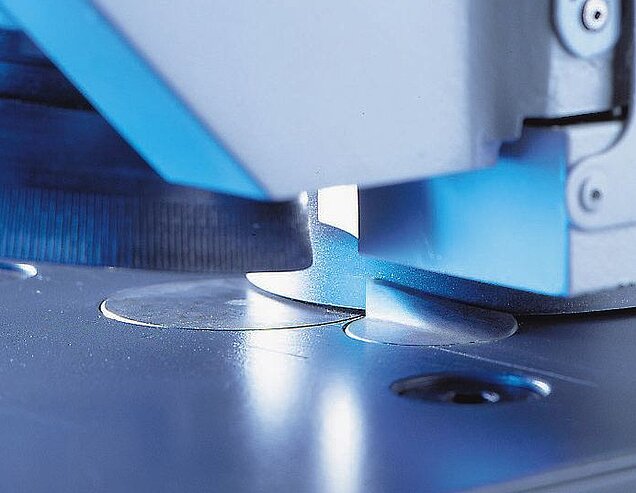

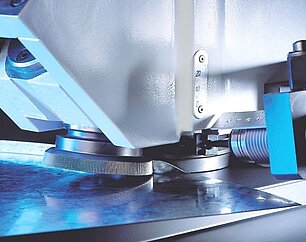

Flexible forming

The forming rolls of the RAS flanging machine can create different flange heights - matching the required joints. For Pittsburgh joints flange heights of 8 and 10 mm should be selected. Snap-lock joints require flange heigths of 10 and 11.5 mm. The automatic sheet guide simplifies the workflow so that even less experienced operators achieve constant forming results.