TouchScreen control

positions the stop to the

programmed dimension

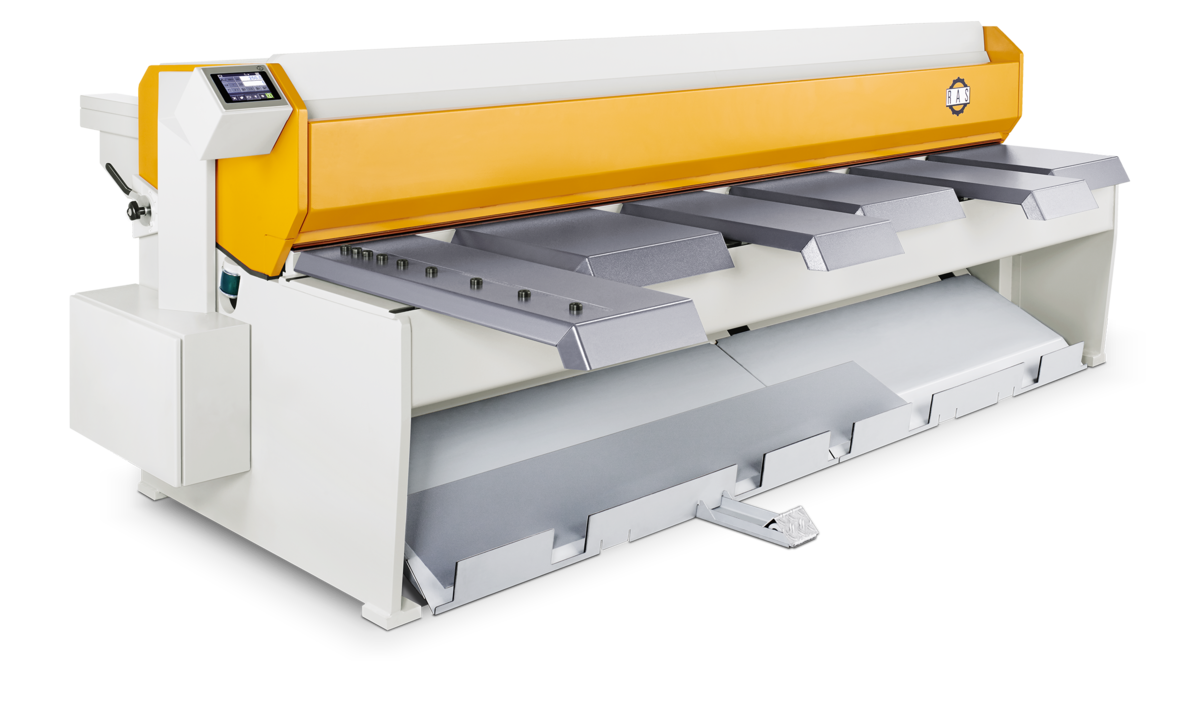

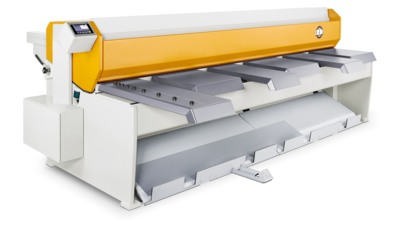

PRIMEcut Swing Beam Shears

Machine highlights

- Swing beam cutting for accurate dimensions and straight cuts

- Low rake angle for twist-free cuts

- Long cutting blade lifetime

- Sorting cut pieces during cutting (to the front or the rear)

- Sheet support and sorting system reduces staffing needs

TouchScreen Steuerung

The Touch-Cut control positions the backstop to the programmed dimension and cuts the required number of pieces. The operator can program a single program line or can create entire cutting programs.

- Very easy to use Touch control

- Mainly craphical icons

- Up to 50 programs with 20 lines each can be stored

- Single or continuous stroke mode

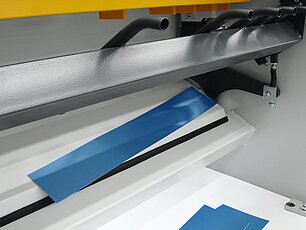

Precision cuts

The CNC backgauge positions the blank precisely within the 750 mm stop depth. A bright LED cutting line illumination simplifies the work, if the blanks need to be positioned below the shear blades using marks.

- Beveled shear tables for fast working sequences

- Adjustable bolts of the squaring arm (adjustment in case of wear)

- Self-cleaning of the squaring a while moving the blank

- LED cutting line illumination

- Downholder with wear-resistant rubber strip (cutting without marks)

- Optional 1500 mm table extension supports large workpieces

- Ball rollers for easy movement of heavy metal parts

- Front stops for positioning from the front

- Adjustable angular stop for angular cuts

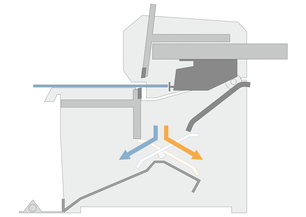

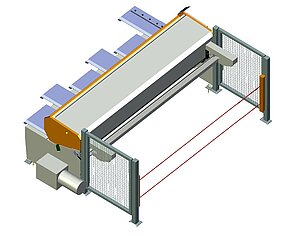

Cutting and Sorting

The sheet support guides even the thinnest materials horizontally and accurately to the backstop. A foot lever position determines whether the parts chute delivers cut pieces to the front or the rear.

- Sheet support system guides the parts horizontally to the backstop

- Precision cuts

- After cutting: Sheet support system tilts downwards

- Foot lever for adjusting the parts chute

- Cut piece sorting to the front or the rear

- Wider cuts will be delivered into the front part collectors

- Smaller cuts and trim cuts delivered to the rear

- Parts collectors receives the blanks

- Moveable stacking carriage: Collection of cut parts and transport

|

RAS 53.30 |

|---|---|

| Cutting length max | 3100 mm / 122" |

| Material thickness max (400 N/mm² / 58,000 PSI) | 3.0 mm / 11 ga |

| Backgauge | 5–750 mm / 0.2"–29.5" |

| Sheet support | yes |

| Part sorting | yes |

| Blade clearance adjustment | yes |

| Strokes/min | 26 |

| Blade angle | 1.1° |

| Cutting technology | Swing beam |

| Machine dimensions (incl. table extension) | 3920 x 2370 mm / 155" x 93" |