Simple automation when

loading blanks and stacking

the finished bent parts

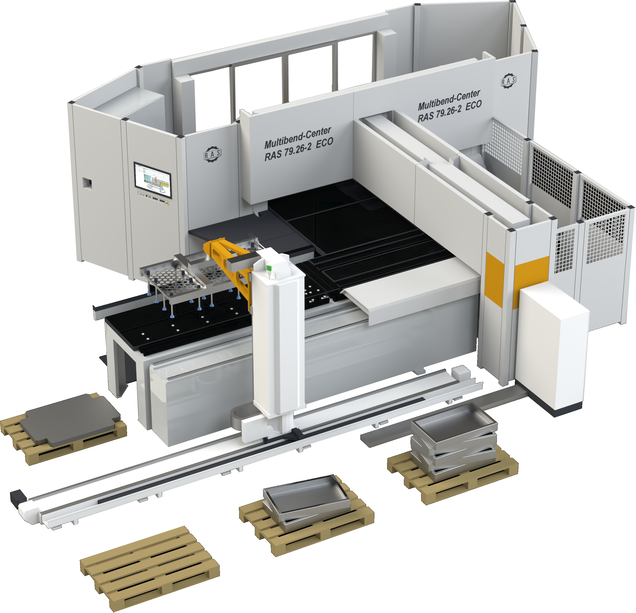

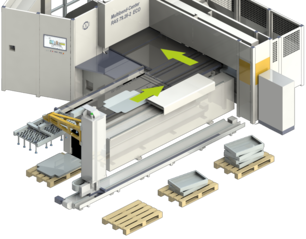

Multibend-Center ECOauto Bending centers

ECOauto: Multibend-Center ECO with autom...

MBC ECO: Equipment for leather industry

Multibend-Center ECOauto: Automatic fold...

Machine highlights

- Manual blank loading

- Manual unloading of bent parts (same side)

- Automatic blank squaring

- Automatic UpDown bending sequences

- Automatic tool setup

- Highest level of productivity

- Highest level of precision and repeatability

- Scratch free bending, no wear of tools

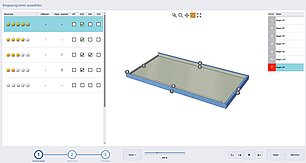

- One-click part programming

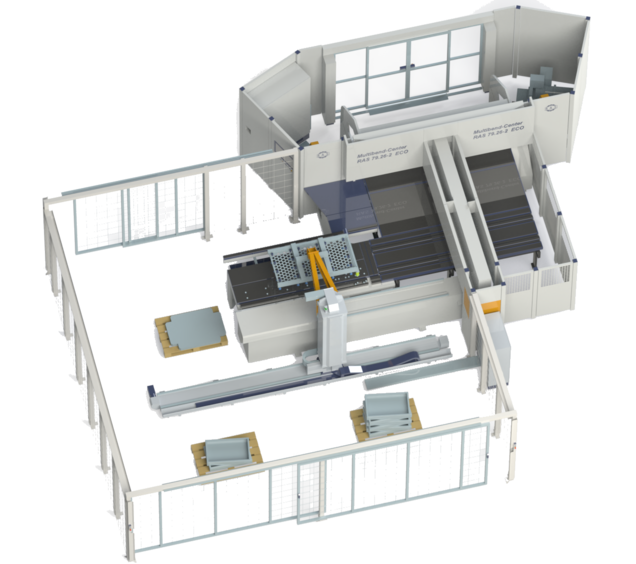

- Small floor space required

The equipment package

The Multibend-Center ECOauto includes:

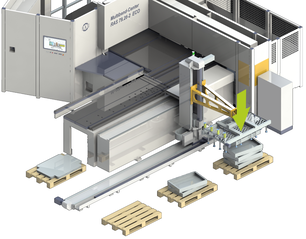

- Automatic blank loading from a single stack

- Suction cup measuring table with brushes

- Magic-Eye blank scanner for optical measuring

- Automatic blank transfer to the main manipulator

- Manipulator rotates and positions the parts

- Up and down bending

- Tool changer for automatic upper beam tool setup

- Tools for upper beam, folding beam and lower beam

- Roto-foot corner tools for rotation into and out of bent flanges

- Horizontal stacking of the bent parts

Palletizer Automation

- Loading system for automatic blank feeding from a single stack with identical sheets lined up according to a reference edge

- Picking up and horizontal stacking of bent parts on pallets

- Suction frame includes the following functions:

- Peeling of the top blank with peeling suction cups

- Fast manual adjustment of the suction cup positions

- Safety system with electrically monitored doors

Optionally the package can be completed with:

- Bendex Office software

- Automatic programming of the bending sequences

- Ranking of alternative bending sequences

- 3D bending sequence simulation

- Software updates of the Bendex Office software for one year

- Folding beam with manual crowning option

- UpDownTools for interrupted bend lines

- Tab tools for bending welding tabs

- Reinforced tools for 2.5 mm mild steel components

|

RAS 79.22-2 ECO-AUTO |

RAS 79.26-2 ECO-AUTO |

RAS 79.31-2 ECO-AUTO |

|---|---|---|---|

| Working length max | 2160 mm / 85" | 2560 mm / 100.8" | 3060 mm / 120.5" |

| Material thickness max (400 N/mm² / 58,000 PSI) | 2.0 (2.5) mm / 14 (13) ga | 2.0 (2.5) mm / 14 (13) ga | 2.0 / 14 ga |

| Box height max (four sides) | 203 mm / 8" | 203 mm / 8" | 203 mm / 8" |

| Blank length max | 2260 mm / 88.9" | 2660 mm / 104.7" | 3160 mm / 124.5" |

| Blank width max | 1500 mm / 59" | 1500 mm / 59" | 1500 mm / 59" |

![[Translate to English:] Aufnehmen des Biegeteils durch den Saugrahmen des Palletizers](/fileadmin/_processed_/2/d/csm_Ablauf_Teil-Aufnehmen_8752355bba.png)