Complex geometries can

be bent due to large free

areas around the tools

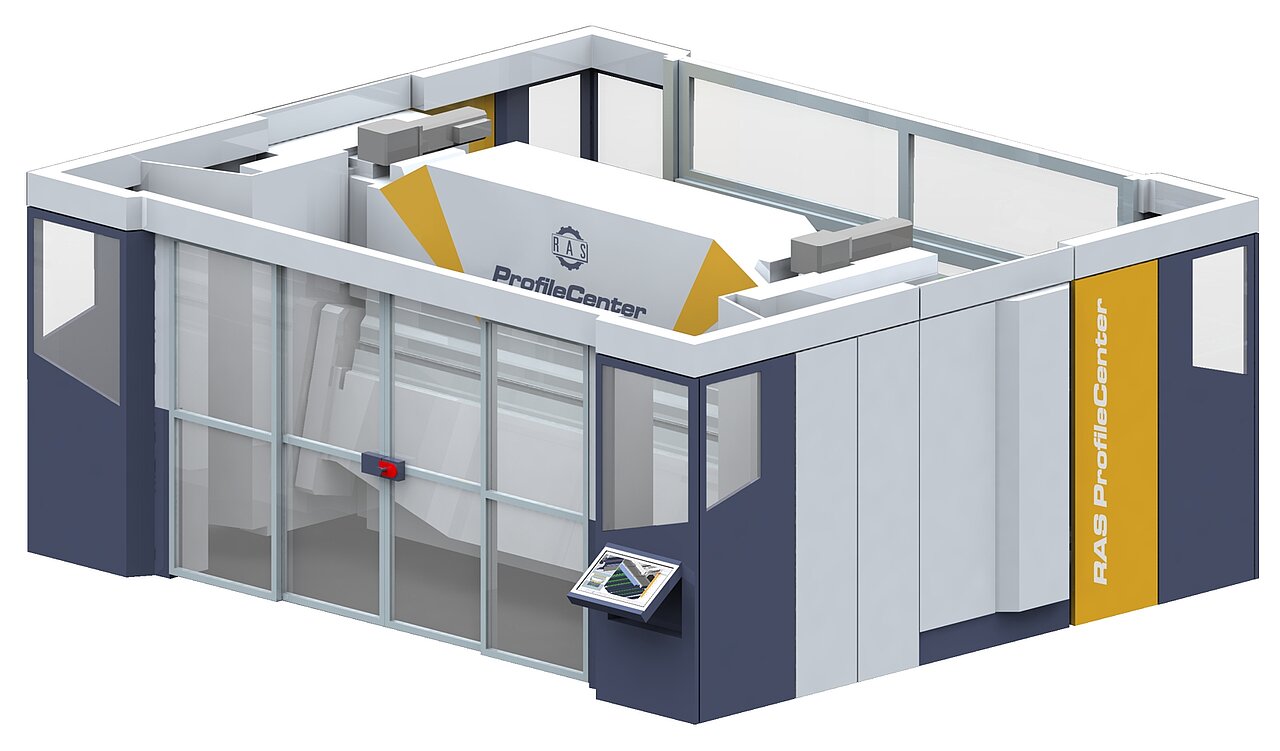

ProfileCenter Bending centers

RAS ProfileCenter

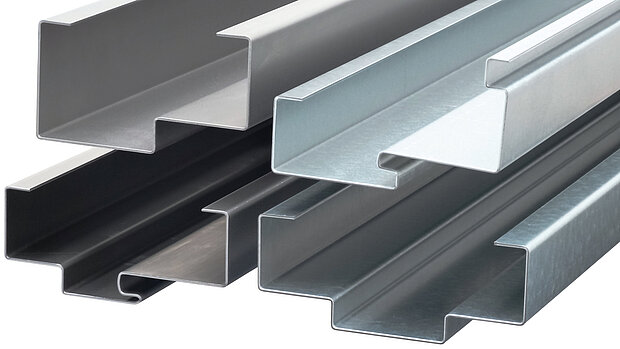

ProfileCenter: Electrical cabinet compon...

ProfileCenter: Door frames

ProfileCenter: Cold room profile

Bending 2 mm mild steel door frames

RAS ProfileCenter: Bending door frames

RAS ProfileCenter

ProfileCenter: Bending door fraqmes at F...

ProfileCenter: Bending steel frames

ProfileCenter: Make-Up Door Frame

Profile bending

Precisely in batch size 1

Flexible and automatic profile bends profiles such as door frames, window frames, elevator entries, electrical cabinet components or cable ducts in batch size 1. The unique FlexGripper handling system moves, rotates and flips the blank automatically during the bending process.

- Fully automated squaring, handling, bending and

unloading of profiles - Flexible bending - up and down

- Automated bending sequences: short cycle times, low costs per part

- No manual interaction needed: high productivity

- Highest levels of precision and repeatability

- Scratch-free bending: no tool wear

- Ideal for batch size 1

- Machine automatically adjusts to thicknesses and material type

- Automatic one-click part programming

- No operator bending expertise required even for complex profiles

Flexible and automatic profile bending

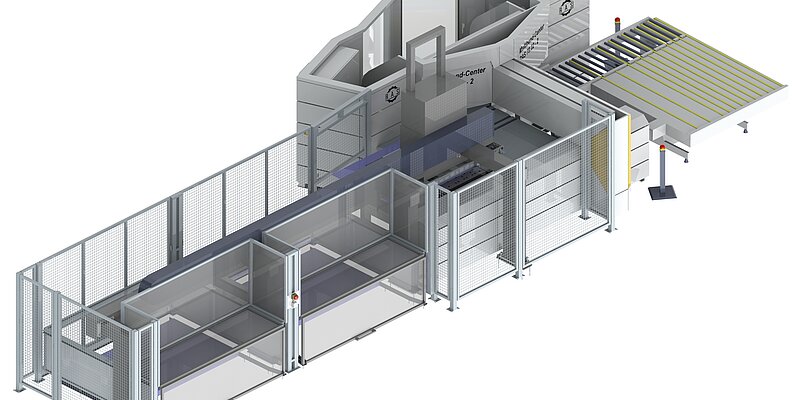

The Profile Center is a bending center for metal components up to 3200 mm in length and 700 mm in width. The capacity of the machine is designed for 2 mm mild steel or 1.5 mm stainless steel materials. The Profile Center uses the folding technology for flexible folding of profiles such as door frames, elevator parts or cable ducts. Precision bending in batch size 1 is no longer a dream, but reality with the Profile Center!

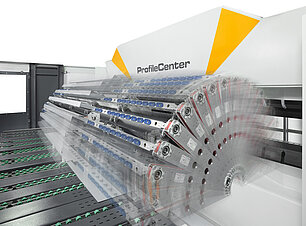

FlexGripper handling system

The unique FlexGripper Positioning System moves, rotates and flips the blank automatically during the folding process. Its multi-flexible suction frame grips the part with up to forty suction cups. The vacuum is generated by an on-board vacuum pump. The suction bar can grab the blank from below, from above or from behind and can automatically change its access position during the folding sequence.

- Automatic blank squaring

- No additional gauging during the bending sequence

- Fast bending sequences, high productivity

- Flexible gripper position: from below, above and from the rear

- Varied part geometries

- Rotation of the hand axis (suction bar)

- 5 suction circuits with 8 suction cups each

- Integrated vacuum pump with demand-oriented air consumption

Suction frames

There are two suction frame options available for the FlexGripper handling system. To cover the complete range of possible material thicknesses and blank dimensions, the wide suction frame will be used. A narrow suction frame is also available for smaller profiles (e.g. multi-part frames). With this suction frame, however, max. sheet thickness and max. blank dimension are reduced.

- Wide suction frame: Straight suction surface on the profile of 33 mm required

- Narrow suction frame: Straight suction surface on the profile of 20 mm required

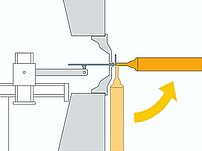

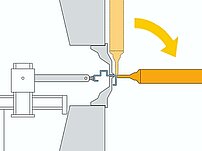

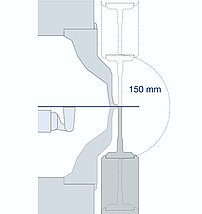

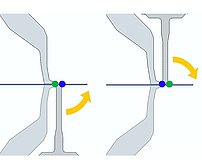

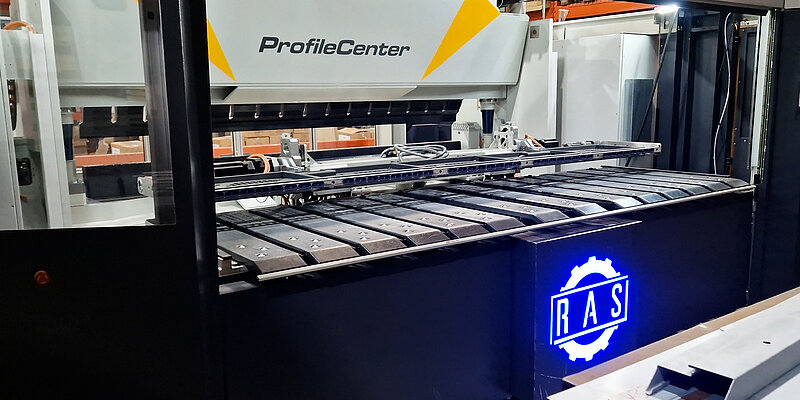

Bending up and down

The ProfileCenter automatically bends complex profiles without operator intervention. The bending center bends up and down with high speeds.

- 8 servo axes run precisely and repeatably

- Bending without scratch (stainless steel, coated sheets)

- No material build-up on the tools (consistant bend angles)

- No wear on tools (long lifetime)

- Automatic pendulum movement when changing the bending direction

- Passing of already bent flanges up to 150 mm long

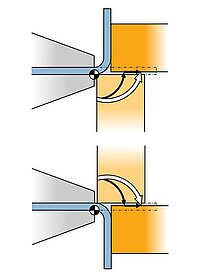

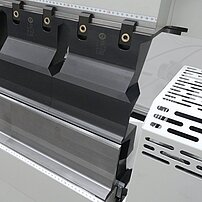

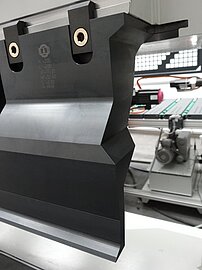

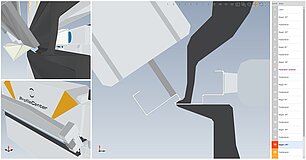

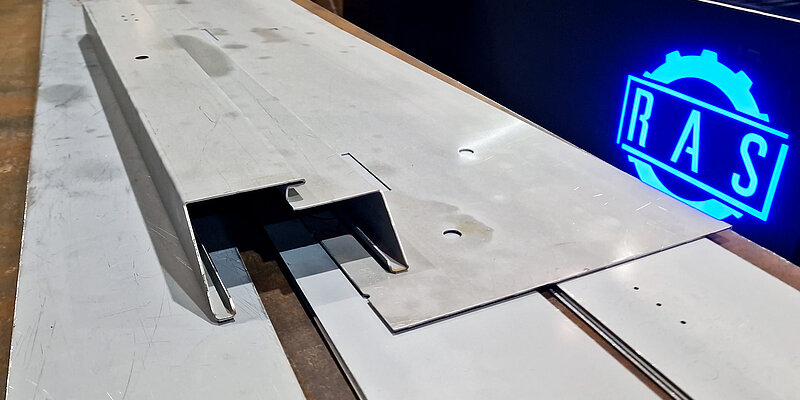

Slim tools

The folding technology is based on the moving folding beam. Its high and slim folding beam tool is exactly designed for the profile bending requests. The tools of the upper and lower clamping beam come with delicate geometries and with huge free space areas.

- Rear-free H-tool for slim geometries

- Front-free V-tool for pre-bending sealing seam geometries

- Large free areas for flexible part designs

- Finite element optimized tools

- Slim tool for filigree bending geometries

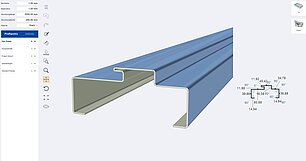

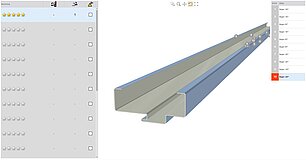

Automatic One-click programming

Making the complexity of the bending process manageable, the ProfileCenter uses a unique and innovative one-click programming software. The operator just drags-and-drops a STEP file of the profile into the Bendex software. With a single mouse click the part is programmed.

- Importing the STEP-file of the part

- Exact and error free CAD data transfer

- Automatic programming of the bending sequence with a single mouse click

- No expert knowledge required for programming

- New products can already be evaluated during the design process

- Software proposes the best bending sequence with a 5-star ranking

- Exact bending results (flange dimensions and angles)

|

RAS 79.30 |

|---|---|

| Working length | 3200 mm / 126" |

| Material thickness max (400 N/mm² / 58,000 PSI) | 2.0 mm / 14 ga |

| Material thickness max (700 N/mm² / 101,500 PSI) | 1.5 mm / 16 ga |

| Blank dimensions min | 100 x 600 mm / 3.94" x 23.6" |

| Blank dimensions max | 700 x 3200 mm / 27.6" x 126" |

| Z-dimension min | 14.5 mm / 0.57" |

| One straight profile surface with wide suction frame min | 33 mm / 1.30" |

| One straight profile surface with narrow suction frame* min | 20 mm / 0.79" |

| Part weight max | 35 kg / 77 lbs |

| Programming | automatic |

| Machine dimensions | 5400 x 5200 mm / 213" x 205" |

In the heart of Ireland, Fireblock, a visionary manufacturer of fire and explosion resistant doors and windows, has achieved a remarkable breakthrough in metal fabrication. By implementing advanced technologies, the company has managed to increase productivity fivefold while establishing new quality standards. Read here how this is possible in detail

![[Translate to English:] Biegeanlauf mit Umgreifen des FlexGripper Handlingssystems](/fileadmin/_processed_/d/3/csm_7930_Biegeablauf_02_6228297e03.jpg)

![[Translate to English:] Die Anschläge richten die Platine im Arbeitsraum automatisch aus](/fileadmin/_processed_/2/7/csm_RAS_ProfileCenter_03_9e4236ecd5.jpg)

![[Translate to English:] FlexGripper Positioniersystem](/fileadmin/_processed_/3/0/csm_DSC03158_daa5841abd.jpeg)