The bending beam of the

TURBObend ensures exact,

repeatable bent parts

TURBObend Bending centers

RAS TURBObend Metal folding machine

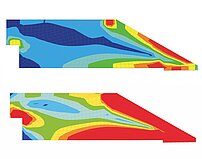

RAS TURBObend: CrownTool 10 mm

RAS TURBObend Metal folding machine

RAS TURBObend Metal folding machine

- Bending profiles for roof, wall, facade

- Easy to use (short training period, changing operators)

- Ideal for all materials: copper, titanium zinc, aluminum, steel, stainless

- Ideal for all typical sheet thicknesses: 0.5-1.2 mm, sometimes > 1.2 mm

- Large free space for a wide range of part geometries

- Automatic gauging system (repeatable profiles, no marking)

- Fast machine (earlier on the construction site)

- Low unit costs (one-man operation, low investment)

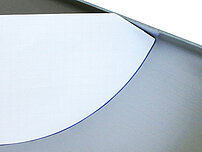

Upper beam

The TURBObend's upper beam is an engineering marvel. It's eccentric elbow pivot opens and closes the upper beam quickly, powerfully and incredibly accurate. This means the TURBObend can create incredibly accurate bends and hems while offering superior longevity and low maintenance.

- Fast closing/opening movements

- Hems: closed, open, tear-drop shape

- Large free space in front of the upper beam (part design flexibility)

- Rigid upper beam for straight bends

- Speed normal and reduced (for marking work)

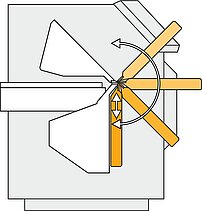

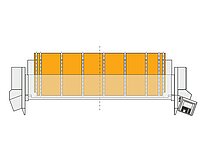

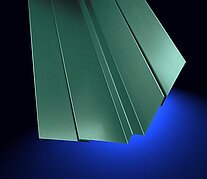

Folding beam

Optimized for maximum stiffness, the folding beam of the TURBObend creates most accurate and repeatable parts. With its dynamic movements, the TURBObend ensures maximum productivity and unheard-of speed. The machine makes the material thickness adjustments automatically, not the operator, so they will always be correct.

- Fast movement: short production time

- Deep folding beam: excellent bend results

- Automatic adjustment to material thickness

- No downtime for machine adjustments

- Gentle and scratch-free bending of coated materials

- Long machine lifetime

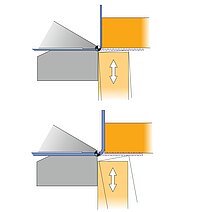

Gauging and sheet support system

The fingers of the stop system position the workpiece for each bend. All stop fingers disappear below the table when the bending part has to be turned on the sheet support system.

- Fast positioning, repeatable operation

- No 2nd operator (50% cost saving)

- No marking (30% time saving)

- Sheet support tables hold the weight of the sheet

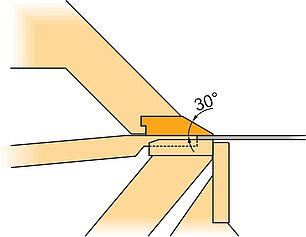

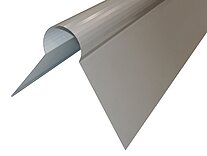

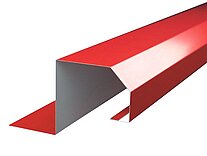

Versatile tools

The TURBObend creates all profiles with a one-piece upper tool. For the folding beam different tool widths are available. The CrownTool is a folding beam tool with an integrated and adjustable crowning system. It is extremely suitable for radius bending.

- Large free spaces for unlimited part design ideas

- Folding beam tools for different thicknesses and Z bends

- CrownTool with adjustable crowning for radius bending

- CrownTool tool widths 10 mm and 15 mm available

- Lower beam tools with finger pockets for stop fingers

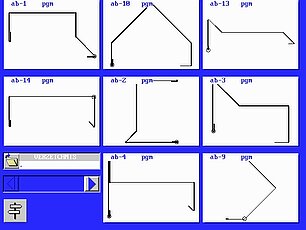

Touch&More control

Use your finger to draw the part with flanges and angles on the screen of the Touch&More control. The software shows the part together with tools and machine components in the later working situation.

- Control panel build-in side stand

- Drawing of the part with the finger

- Technology tables (angle correction/unfolded length)

- Programm, part and actual bending step are shown at a time

- Program library with profile icons

- Operator guidance (text and symbols)

- Speed Optimizer for 15% less cylce times

- EasyGo program for occasional operators