Folding technology innovations

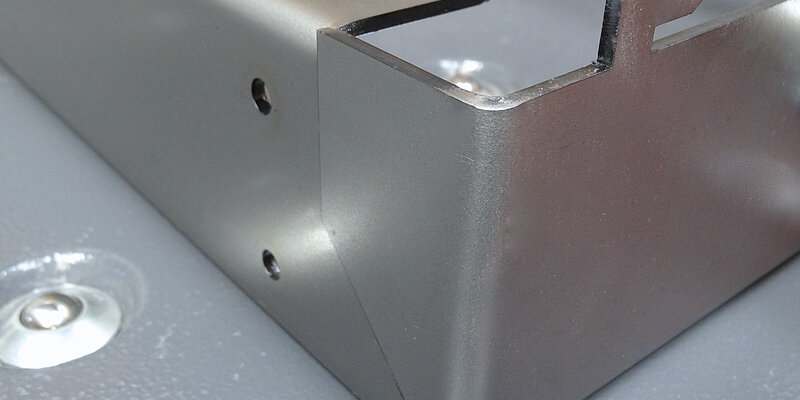

that result in precision parts

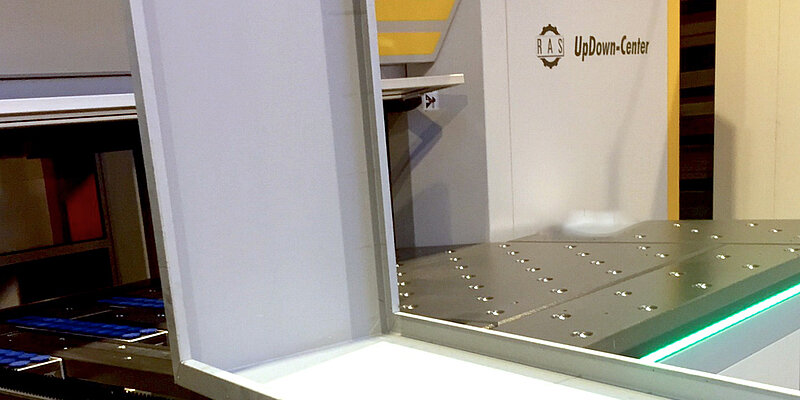

UpDownCenter-2 Bending centers

UpDownCenter-2: 600mm deep electrical en...

UpDownCenter-2: Programming and Bending

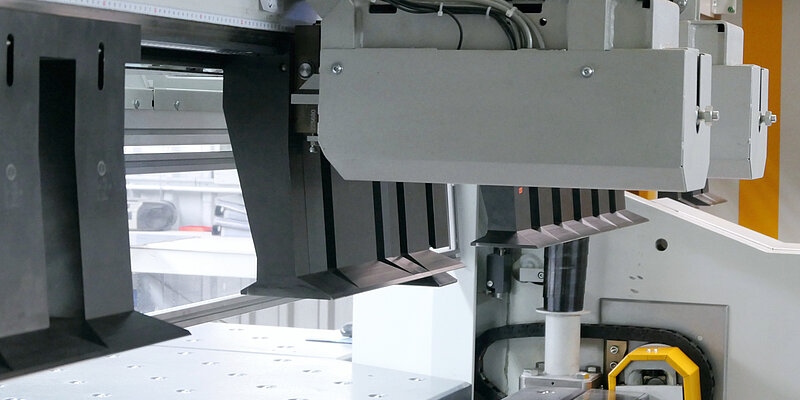

UpDownCenter-2: Drawer with UpDownTools

RAS UpDownCenter-2: Soundproof enclosure...

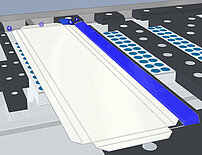

UpDownCenter-2: Kit Production of aircon...

UpDownCenter-2: Air conditioning unit co...

UpDownCenter-2: Folding electrical cabin...

UpDownCenter-2 bends small electrical ca...

Panel bender UpDownCenter RAS 78.43-2

UpDownCenter: 400 mm electrical cabinet ...

UpDownCenter: Folding Safety Doors

UpDownCenter-2: 400 mm deep electrical c...

RAS UpDownCenter

UpDownCenter: Rößler GmbH

UpDownCenter: Soundproof enclosures

UpDownCenter: von Arb SAS AG, Switzerlan...

UpDownCenter bends medical furniture

RAS UpDownCenter: Side panel with large ...

RAS UpDownCenter: Cabinet door with rad...

UpDownCenter-2: Electrical cabinet with ...

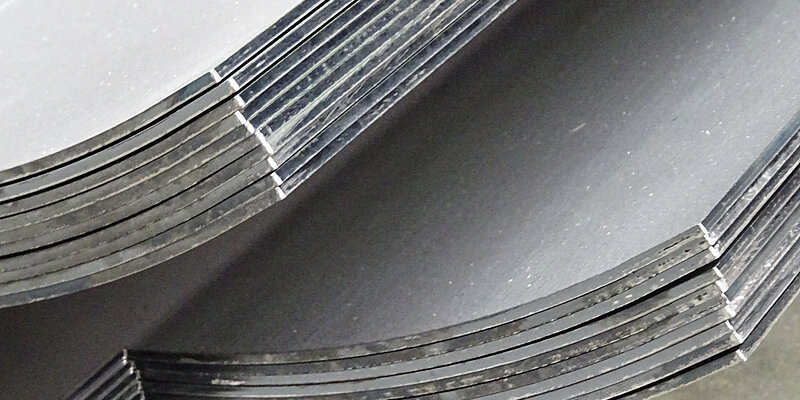

RAS metal folding: Bending radii without...

UpDownCenter: Electrical cabinets

UpDownCenter: Fire hose cabinets

RAS UpDownCenter: Folding Center

UpDownCenter: Aluminum composite facade ...

UpDownCenter: Metal facades

UpDownCenter: Refrigerated counter

UpDownCenter: Machine covers with radii

UpDownCenter: Facade cassette with hook

UpDownCenter-2: Bending radii of any siz...

Frea & Frea: Metal facades

RAS UpDownCenter-2 at Tamellin (Italy)

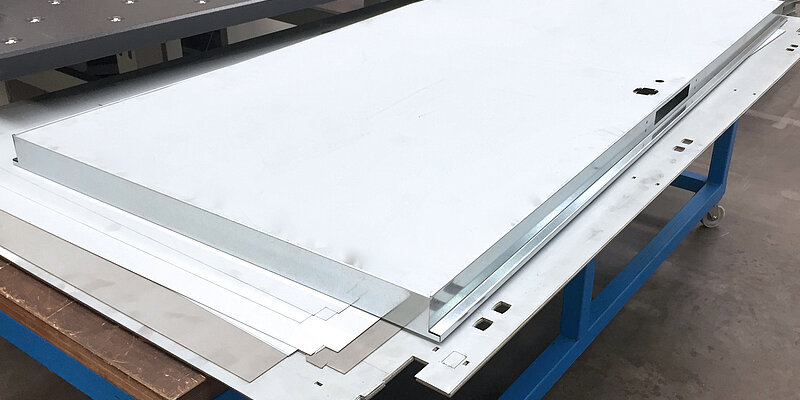

UpDownCenter-2: Bending large panels

UpDownCenter-2: Hemming with tool heel

Bending center

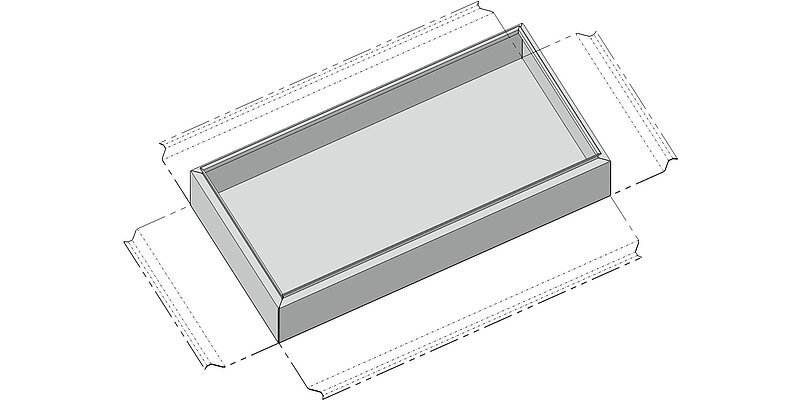

The semi-automatic UpDownCenter-2 for high-precision panels and boxes

The UpDownCenter-2 is a semi-automatic bending center for high precision panels and boxes up to 4060 mm bending length and up to 600 mm box height. With up to 4 mm mild steel bending capacity, it is ideal for thin and medium material thicknesses. The machine can be operated from the gauging system side. Bent parts with long and high flanges can be also unloaded from the folding beam side.

- Automatic tool changer (tool setup ca. 30-45 sec)

- Automatic bending sequences, Bending up and down

- Single operator can bend very large parts

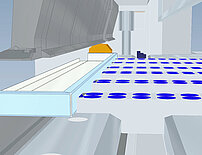

- Automatic part positioning by suction cup pads

- Operation from the gauging system side

- Automatic programming of bending sequence

- Incredible dimensional and angle accuracy

- Bending of boxes with radii and oblique base shapes

- Bending of parts with embossings, large holes etc.

- Automation for high part diversity up to batch size 1

Even the first bent part is accurate

The tool changer cuts set-up times and increases productivity, especially for small production lots or when a tool change is required within the bending sequence. In addition to up and down folding and the automated PosLift part positioning system, the automatic creation of bending programs is another highlight of the machine.

Here are some samples of how accurately the software programs a parts starting from the imported STEP file and how accurately the machine already bends the very first part.

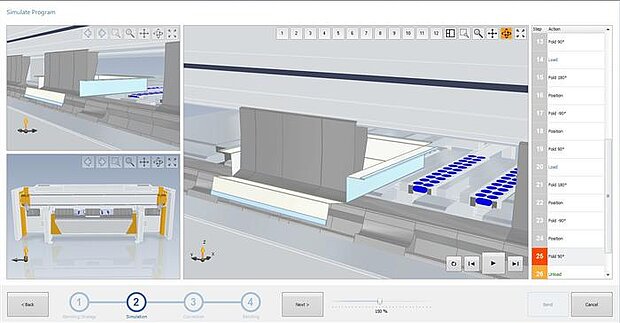

A dream come true

The ingenious Bendex software programs the bending sequence with a click of the mouse. Simply import a STEP file of the part by Drag & Drop into the software. That's it! With one click of the mouse, the software automatically programs the entire bending sequence and shows a variety of possible programs in seconds. With a 5-star rating, the software suggests the best bending sequence. A 3D simulation shows all details of the bending sequence. This allows the feasibility to be checked in the office - even before the first blank is produced. After starting the program, the software guides the operator through the bending sequence. The software shows the loading direction, the rotation of the part and the foot switch operation.

- Import of STEP files (alternatively: DXF, DWG or GEO)

- Software automatically recognizes the bending lines and bending parameters

- Automatic programming of the bending sequence

- Ranking of alternative bending strategies

- 3D bending sequence simulation

- No bending expertise required

PosLift gauging system

Versitile gauging of parts

The UpDownCenter offers numerous options for squaring and gauging the blanks. But no worry: The software calculates the best gauging option automatically and proposes it to the operator. If the operator selects another possibility, the program will be adapted immediately.

- Right and left stopper head with 3 stop positions

- Squaring the blank using notches

- Squaring the blank using the outer edge

- Squaring the blank using pre-bent flanges

- Folding beam used as a stop for oblique parts

- Pop-up squaring arm for parts being narrow and long

- Safety light beam and colored LED access indicator

Position parts with ultimate accuracy

After squaring the parts the suction cups of the gauging system take over the blank and position the workpiece with an accuracy of +/- 0.01 mm for each bend. The UpDownCenter finishes one side of the part before the operator turns the blank to the next side.

- Easy operation. The part rests on gauging system

- No skilled operator level required

- A single operator bends even large and heavy parts just by himself

- Also thin and flexible blanks are easy to handle

- Safe and ergonomic operation

- No exhausting part lifting and holding

- 8 vacuum module pads with 22 suckers each hold the part safely

- 10 front suction cups for positioning very narrow parts

- Suction cups for small parts expand the range of applications

- 12 suction circuits for optimum energy efficiency

- Software detects holes in parts and calculates the vacuum level

- Vacuum modules are able to lift parts with negative flanges by 85 mm

- Vacuum pump generates the required compressed air

- Vacuum modules lower for part rotation

- J-shape table extension supports large workpieces

PosLift gauging system with brush table

The RAS UpDownCenter panel bender is also available with a brush table. This solution is very useful for extremely thin sheets, as they are used for refrigerated cabinets and in the shop fitting industry.

- Easy and quick operation.

- Also thin and flexible blanks are easy to handle.

- Prevents damages to the sheets edges during loading and blank rotation.

- Prevents damages to the suction cups.

Quick tool change

The gripper arms of the tool changer take the tools from the magazine and place them precisely in the upper beam. Fast set-up times lead to high productivity and low unit costs.

- Bending small production batches economically

- Software calculates fastest setup strategy

- Set up of even heavy tools (300 mm tool high weighs 15 kg)

- Tools change also within the folding cycle (bending long before short side)

- Asymmetrical tool setup possible

- Tool magazine left and right

- Automatic tool clamping

Tools

Upper beam tools

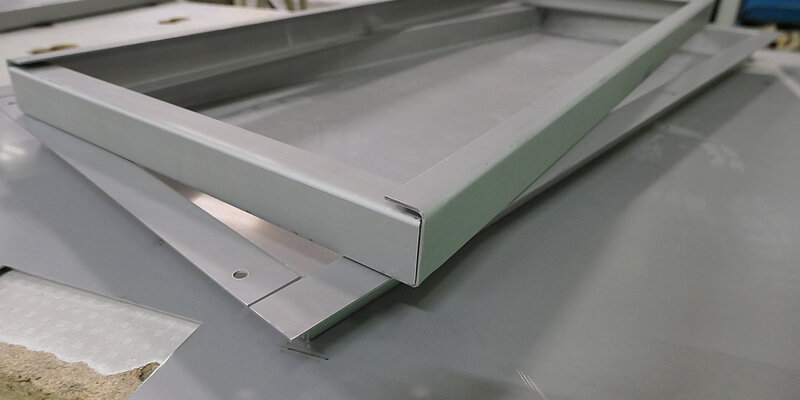

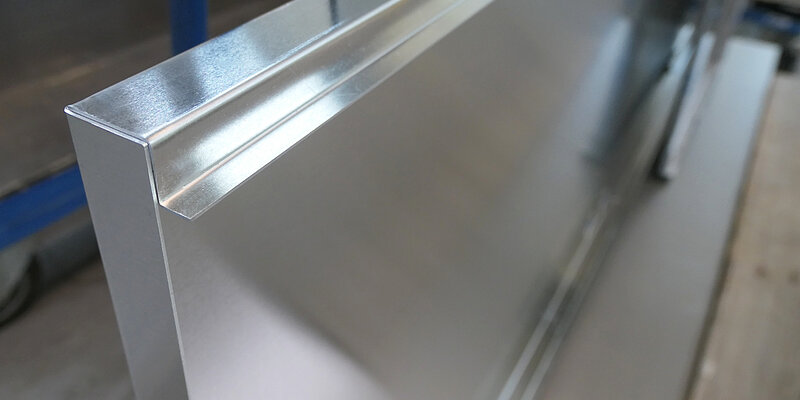

The upper beam tools of UpDownCenter-2 are segmented. This allows the tools to be individually setup for each part length. With tool heights of up to 600 mm, the machine is also ready for deep boxes and enclosures.

- Only one set of upper beam tools for great part design flexibility

- Tool heights 250 mm, 300 mm, 350 mm, 400 mm and 600 mm

- Bending deep four-sided parts

- Tools with heel for closing hems

- No wear of tools

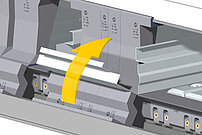

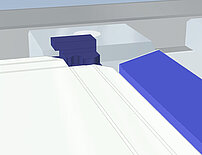

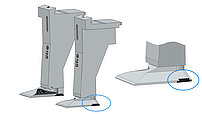

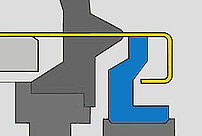

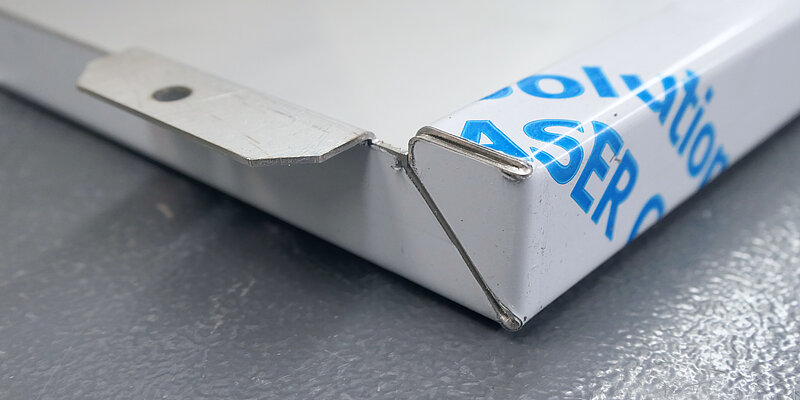

Roto-foot corner tools

The roto-foot corner tools can rotate in and out from pre-bent side flanges.

- Enlarged application range

- Four-sided parts with lateral C-bends can be bent

- Set up by tool changer

- Flexible position within the working length

- For very sensitive material surfaces (mostly stainless steel), roto-foot corner tools with an inserted plastic heel are also available

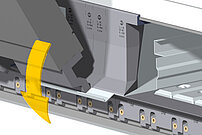

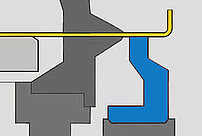

Folding beam tools

The folding beam tools of the UpDownCenter-2 are also segmented to allow slots for protruding flanges or tabs.

- Variety of tool widths for small Z dimensions and large sheet thicknesses

- Programmed folding beam pendulum when changing bending direction

- No manual replacement of pendulum stops required

- Two directions of use for front or rear tool free space

- Fast setup, high productivity, low unit costs

- Automatic folding beam tool clamping

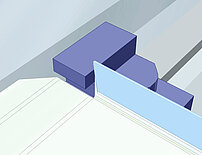

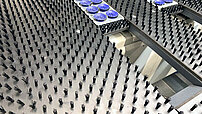

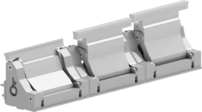

UpDownTools

The UpDownTools can be programmed for three different working heights. This allows bending of tabs, window bends, oblique blanks, etc.

- Maximum part design flexibility

- Different height positions of the UpDownTools right and left

- Different height positions of the UpDownTools also on one side

- Quick set-up (tools are automatically clamped)

Safety

Latest safety systems

The UpDownCenter-2 is equipped with the latest two-channel safety systems.

- Safety light beam at the stop: no access in the automatic sequence

- Colored LED access indicator on the gauging system

- Sliding door on the cell side when working from the gauging system

- Safety light curtain when working from both sides

- Colored LED access display at the cell (with light barrier)

- Protection element prevents access when changing tools

- Protection element automatically opens for removal of high parts

|

RAS 78.33-2 |

RAS 78.43-2 |

|---|---|---|

| Bending direction | UpDown | UpDown |

| Working length | 3200 mm / 126" | 4060 mm / 160" |

| Material thickness max (400 N/mm² / 58,000 PSI) | 4.0 mm / 9 ga | 3.0 mm / 11 ga |

| Upper beam open height | 850 mm / 33.4" | 850 mm / 33.4" |

| Box height max (four-sided) | 400 mm / 15.75" | 400 mm / 15.75" |

| Gauging system | PosLift | PosLift |

| Programming | automatic | automatic |

| Operation | Gauging system side | Gauging system side |

| Unloading of bent parts | Front or rear side | Front or rear side |

| Tool changer | yes | yes |

| Machine dimensions (Rectangular gauging system) | 6400 x 3530 mm / 252" x 139" | 7660 x 3530 mm / 286" x 139" |

| Machine dimensions (J gauging system) | 6400 x 5230 mm / 252" x 206" | 7660 x 5230 mm / 286" x 206" |

A manufacturer of individual electical enclosures compared production on his existing press brakes with bending on a RAS UpDownCenter panel bender and realized remarkable effects. The astonishing finding: The improvements in bending also translate into improvements in cutting and in the downstream welding process. Where do these effects come from?

Soundproof machine enclosures are individually designed according to the customer's needs and the technical requirements for noise reduction. Optimal accessibility determines the position of doors, loading openings and viewing windows. This individualization and concentration on niche applications demands maximum flexibility and skillful handling of small batch sizes. The RAS UpDownCenter is predestined for exactly such jobs. 4060 x 1500 x 3 mm bending capacity are the technical parameters of this panel bender. The machine name says it all, as the UpDownCenter can bend up and down without a need to flip the workpiece. A tool changer automatically sets up the tools of the upper clamping beam.

If you visit the website of Zepter GmbH + Co. KG you will find a huge range of products made of sheet metal. You will find control tower for air traffic control and equipment for mobile containers. In addition, the contract manufacturer from Neunkirchen (Germany) also produces sheet metal components for machine enclosures, emergency services vehicle bodies, as well as customized control cabinets and control desks. In addition, Zepter produces their own product: functional furniture for hospitals and medical laboratories. It goes without saying that this diversity requires high levels of flexibility. The RAS UpDownCenter panel bender produces the required components from individual parts to small batches.

Alphatec Schaltschranksysteme GmbH produces cabinets for the electrical industry. These include meter cabinets, media columns and converter cabinets, e.g. for photovoltaic systems. About 35 percent are custom-made cabinets in small batches. For bending Alphatec uses a RAS UpDownCenter bending center. This panel bender bends the blanks up and down, automatically creates the part programs and sets up the tools with an automatic tool changer.

The von Arb AG SAS produces sound proof enclosures. In addition, the company has established itself as a highly flexible job shop. Even special orders can usually be provided with same day delivery. "If you want to produce single customized parts, you have to consider machines that can handle Step files and automatically program the component," says Roman von Arb and adds: "For small production batches, alternating bending directions, large formats and heavy parts the UpDownCenter is unbeatable."

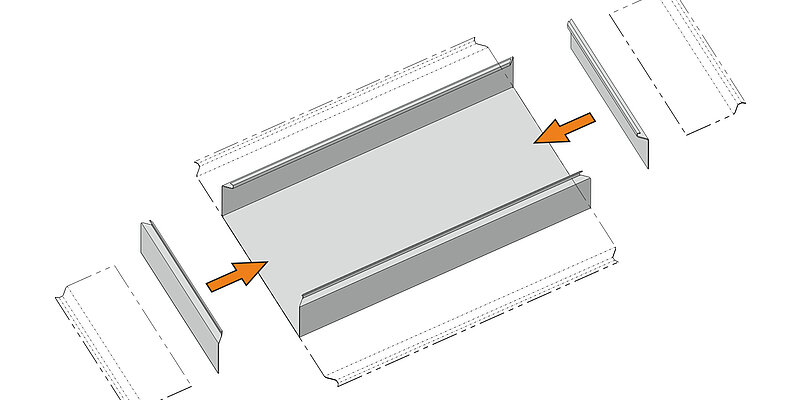

Even for very complex door geometries, the Bendex 1-click programming software automatically creates the bending programs. The safety door panels folded on three or four-sides just will be pushed in each other during assembly.

Geerds Metallbau GmbH has gained more than 40 years of experience and expertise in facade projects. The facade specialists from Groß Welzin pair innovative product design with the latest production technology. The RAS UpDownCenter completes the performance spectrum of this leading supplier in facade technology. The Bendex one-click software programs the parts with a single mouse click. With an automatic tool change and scratch-free folding, Geerds is able to create complex and optically demanding components in small quantities and highly profitable.

The Roessler GmbH from Mertendorf in Germany is a job shop that specializes in enclosures of machine tools. The variety of housings and small batch quantities requires high production flexibility and a high level of vertical integration. When Roessler's customers changed their product to a design with large radii, the previous production with press brakes reached its limits. Today, a RAS UpDownCenter folding system bends the radii automatically.

![[Translate to English:] Entnehmen eines automatisch gebogenen Metallteils mit Radius](/fileadmin/_processed_/5/0/csm_Kaschwig_3D-Ecke-entnehmen_2055824f32.jpg)

![[Translate to English:] Gedämmte Metallkassetten für Wände von Schallschutzkabinen](/fileadmin/_processed_/b/e/csm_Kaschwig_Daemmelemente_865447b9a5.jpg)

![[Translate to English:] Die Platine bleibt immer auf dem Tisch liegen. "Die Zeiten mit Rückenschmerzen sind vorbei", bestätigt Maschinenbediener Fabian Arn.](/fileadmin/_processed_/0/7/csm_DSC00352_3975cd0270.jpg)