Improved seam accuracy

due to longer guide rail

DuctZipper-L Ducting machines

RAS DuctZipper: Duct seaming machine V s...

RAS DuctZipper: L-shape for large air du...

RAS DuctZipper in L-shape: Production se...

RAS DuctZipper with SealJet

RAS DuctZipper: Duct seaming machine V s...

For large ducts and high productivity

RAS has designed the DuctZipper in L-shape especially for large ducts and high productivity. The RAS DuctZipper duct seaming machines reduce the traditional three steps (rollform the receiver lock, rollforming the flange and finally closing the seam) down to only one easy run through the machine. The result is a clean joint and an extremely tight duct.

- Halved staffing needs due to easy handling of large air ducts

- Doubled working speed due to fast workflow

- Low physical strain on machine operators

- Consistent long-term quality due to low machine wear

- 40–50% less space required (possible installation next to a wall)

- Increased safety: Even large ducts keep their shape

- Easy maintenance and cleaning due to good accessibility

Designed for large ducts

The DuctZipper in L-shape is especifically designed for large ducts. However, it also shows benefits when it comes to small and medium size ducts. On the DuctZipper-L the working position is rotated by 45 degrees.

- The horizontal flange of the duct rests on the table

- The vertical flange directs straight up

- Gripping groves simplify holding and guiding of the duct

Halved staffing needs

On the DuctZipper-L, it requires only two operators, who can handle even large 1500 x 1500 mm duct cross sections with ease. Smaller and medium-sized ducts can be completed with a single operator.

- Horizontal machine loading with open duct sections

- Horizontal unloading of finished ducts

- Tipping of the ducts into a stable upright position after unloading

Operating speed doubled

Large ducts can be easily and quickly positioned in the DuctZipper-L. The sheet edges will be just inserted into the guide rail and clamped with the Autopilot. There are no machine support components on the DuctZipper in L-shape and therefore the seaming process can start much quicker.

- The second operator can already insert the following medium size duct

- Unloading of the first duct and clamps the next duct with the AutoPilot

- High throughput, low unit costs

Low load, high productivity

The horizontal loading and unloading of the ducts makes it completely superfluous heaving large and heavy duct cross-sections in and out of the machine.

- Workers can operate mostly in an upright posture

- Low gripping height due to the horizontal-vertical machine setup

- Low back and shoulder strain

- Less fatigue, higher productivity, less sick leave days

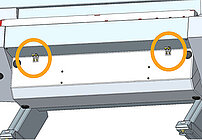

Consistent long-term quality

The weight of the duct presses on the machine only to a small extent.

- The reduced load leads to low wear

- Consistant long-term accuracy of the machine

- The outout table supports the AutoPilot on 2500 mm length

- Extra long ducts safely run through the DuctZipper-L

- Extra wide horizontal table support at the machine

- Stationary or moving table supports the weight of the duct

- Rear wall of the machine provides vertical support

40-50% less space required

A horizontally positioned duct on DuctZipper in L-shape requires less space than a cross-section passing vertically through the machine. In the horizontal position, the flange length of the duct determines the space, while in the V-shape of the diagonal of the duct determines the floorspace requirement. In addition, on the L-shaped DuctZipper both operators are working from the same side of the machine. This allows in small workshops positioning the machine to a wall.

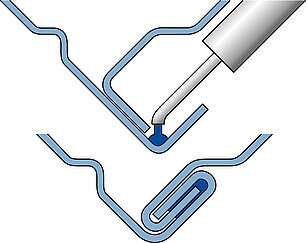

Super tight air ducts

The SealJet additionally seals the seam joint during the run.

- Easy, fast, efficient and clean sealing of the seam joint

- Sensors starts and stop the injection process

- No additional operation steps required

- Recommended sealant: Mez-Bluemastic-Gel

- A container (25 kg) sufficient for approx. 18,000 meters seaming length

- Sealant is temperature resistant from -30°C to +160°C

- Sealant provides corrosion protection (corrosion degree 0).

- Sealant meets the latest hygiene requirements

- SealJet can be retrofitted to existing machines

Increased safety

As even large ducts keep their shape and do not tilt into one another, the DuctZipper-L impresses with an increased work safety.

- Even large ducts keep their shape while running through the machine

- Safe operation for the workers

- Emergency shut-off cord, if an unforeseen situation occurs

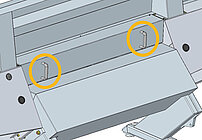

Eased maintenance

As the orientation of the rolls is tilted by 45 degrees less zinc abrasion falls on the bearing points of the forming roll. For regular cleaning the accessibility to the rolls on the DuctZipper-L has been improved.

- For cleaning front and back cover can be simply opened

- Front cover can be tilted down

- Rear cover can be easily taken off