Swing beam cutting

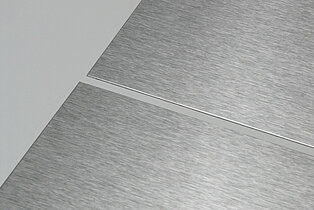

for accurate blank sizes

and straight cuts

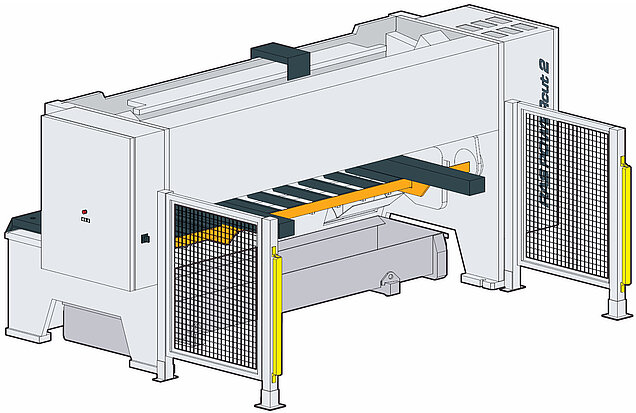

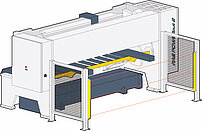

POWERcut2 Swing Beam Shears

Swing beam shear RAS POWERcut 2

RAS SMARTcut Swing Beam Shear

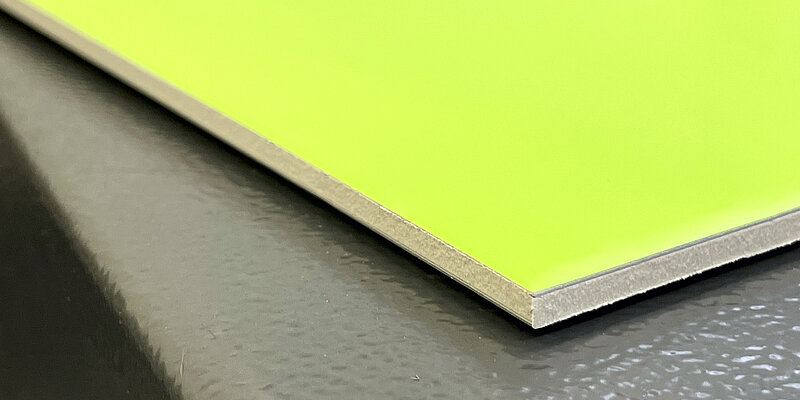

POWERcut2 swing beam shear: Metal facade...

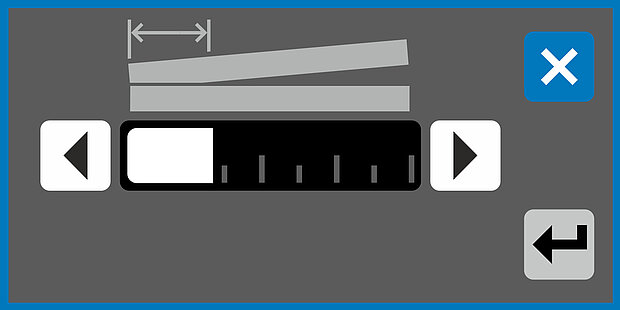

- Low rake angle for twist-free strips

- Large and clear 15" touch monitor with new operating concept

- Sheet support system saves labor costs

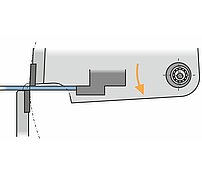

- Fast automatic blade clearance adjustment for thickness and material

- Rapid stroke sequence and adjustable cutting length for high throughput

- Optimal material utilization through deep pockets

- Large shear tables with ball casters facilitate material handling

- Sorting of blanks during cutting (good parts, scrap, small parts)

- Long lifetime of the cutting blades

- LED-illuminated cutting area

Maximum productivity

Speed in all aspects of operation ensures high throughput and productivity:

- Rapid sequence of up to 50 strokes per minute

- Adjustable cutting length for short parts

- Fast backstop movement

- Fast and automatic blade clearance adjustment

- Sorting functions of the sheet support and sorting system

- Single stroke and continuous strokes

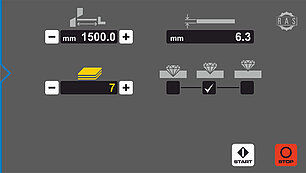

Individual operating concept

The 15" touch monitor offers maximum and individual operating convenience

- Large screen and purely icon based operating functions

- Simple, fast and intuitive inputs

- Movable control panel along the front of the machine

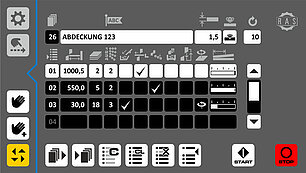

- 3 operating modes for occasional users, more experienced users, experts

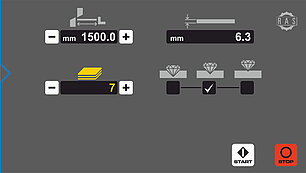

- Simple mode: sheet thickness, material type, stop dimension and quantity

- Advanced simple mode: additional sorting functions and cutting length

- Program mode: Cutting programs with several program lines

- Save and load programs

Best operator ergonomics

The shear table is the operator's direct working area. Its design ensures for easy, quick and efficient material handling.

- Working height 850 mm

- Wide, beveled and rigid tables for quick material handling

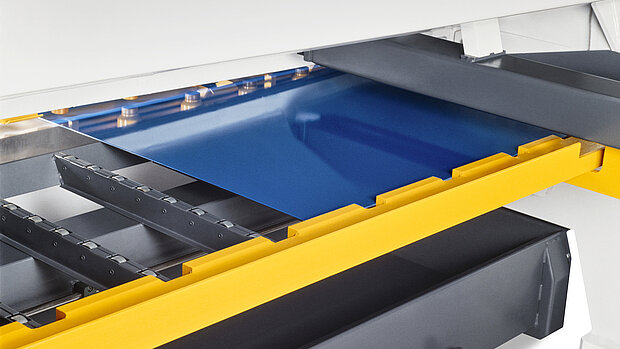

- Ball rollers for gentle metal plate movement

- Recessed grip between shear tables

- Table extensions and table supports for easy access

- Moveable table extensions can be added within seconds

- Table extensions can be easily docked with a lever

- Front stop with fine adjustment

- Adjustable and self-cleaning squaring stop

- Finger safety protection with good visibility

- Deep finger pockets for an optimum material use

- LED workspace illumination

- Hold-down pressure automatically adjusts for slip free cutting

- Easy maintenance and good accessibility when changing the oil

- Large frame cutout for easy blade change

- Highest safety levels by two-channel queries

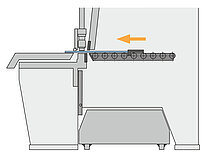

Precise cutting dimensions

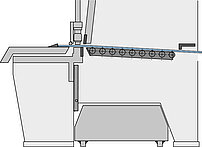

The combination of CNC backstop and sheet support system ensure precise cutting dimensions. The sheet support system guides the sheet to the backstop.

- Sheet in a horizontal position: exact cutting dimensions

- Backstop depths selectable: 1000 mm, 1250 mm and 1500 mm

- Snap-on extensions of the sheet support arms

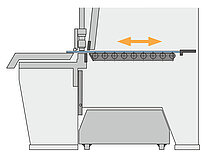

Sorting while cutting

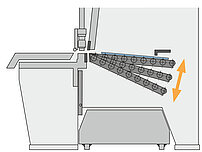

After the cut is made, the sheet support system shows its superiority with multiple material sorting functions:

- Sorting the blanks while cutting increases productivity

- Blanks rolling off in 3 angular positions

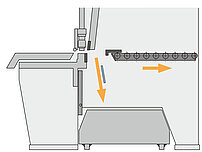

- Low angle for sensitive parts: smooth and gentle delivery

- Steep angle for normal blanks: fast delivery, rapid sequences

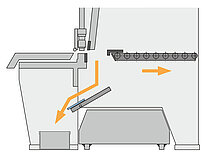

- Return-to-Sender brings cut parts back to the operator

- Safe small parts sorting to the front (max 200 x 500 mm)

- Trim cuts fall into large volume scrap box

- Separation of good parts and scrap during cutting

- Removal of full scrap box to the rear, the right or the left

- No material sorting required below the shear

|

RAS 86.33-2 |

RAS 86.43-2 |

|---|---|---|

| Cutting length max | 3190 mm / 125.5" | 4040 mm / 159" |

| Material thickness max (400 N/mm²) / (58,000 PSI) | 6.3 mm / 1/4" | 5.0 mm / 6 ga |

| Backgauge | 5–1000 mm (1500 mm) / 0.2"–39.4" (59") | 5–1000 mm (1500 mm) / 0.2"–39.4" (59") |

| Small parts chute | yes | yes |

| Automatic blade clearance adjustment | yes | yes |

| Scrap separation | yes | yes |

| Return-to-sender | yes | yes |

| Strokes/min | 30–50 | 28–45 |

| Blade angle | 1.2° | 1.0° |

| Cutting technology | Swing beam | Swing beam |

| Machine dimensions (incl. angle stop and fence) | 4450 x 4050 mm / 175" x 159" | 5400 x 4050 mm / 213" x 159" |

Several industrial companies think that metal shears have no future. However, there is no economical way around shears when it comes to cutting strips and rectangular blanks. Neither punches nor lasers can compete with the efficiency of the shears for such jobs. This is also the case at Gramm GmbH & Co. KG, a specialist for modern, innovative metal roof and façade solutions, who invested in a RAS Powercut2 swing-beam shear.